Since titanium has a low density, it is best suited for applications that call for lightweight components. The aerospace industry is one that utilises titanium socket head cap screws. The use of lightweight Aerospace Titanium Fasteners helps the vehicle achieve its goal of gaining momentum quickly. The material has a lower density than alloys of stainless steel.

In addition to being lightweight, titanium bolts and fasteners have tensile strength characteristics that are practically identical to some premium classes of carbon steel. Aqua regia, seawater, and chlorine are just a few of the conditions in which titanium aircraft fasteners exhibit their ability to resist corrosion. Because titanium has strong resistance to both fatigue and breaking, its use as nuts and bolts is valued in the aerospace sector.

Some pure metals and alloys that are commonly used have a propensity to creep when subjected to high temperatures. However, because the Titanium Fasteners can resist moderate strength without becoming creep-prone, they are beneficial in a variety of sectors. Manufacturers of titanium fasteners advise using these fasteners in the marine engineering sector due to their resistance to salt, brine, or seawater. Titanium 12 Point Bolts are also used in desalination plants and heat exchanger applications for heavy-duty fastening.

before buy from india see Comparision of Titanium Fasteners price with Inconel fasteners price list

| ISO standard | ISO 7380, ISO 4032, JIS standards, ISO 4017, ISO 4033 |

|---|---|

| BS | British standard 57 |

| Size |

M6, M30, M12, M10, M16, (M45), M4, M8, M2, M24, (M3.5), M33, M20, M42, (M14), M5, M48, (M18), (M27), (M22), M36, M3, M160 and as per need |

| Grade | 4.8, A2-70, A4-80, 8.8, A4, A4-70, A2, 18-8 Stainless Steel, Studr Bolt |

| Length | 3 milimeter - 200 milimeter |

| Titanium Fasteners Threads: | METRIC, UNC, BSF, UNF, BSW or as per need |

| DIN | DIN 912, DIN 603, DIN 933, DIN 6923, DIN 931, DIN 7981, DIN 970, DIN916, DIN 934, DIN 7985, DIN 7982, DIN 913, B.S. |

| UTS | UNEF, UNS, NPTF, UNC, NPT, UNF |

| Tolerance | +/-0.01 milimeter - +/-0.05milimeter |

| treatment on Surface |

|

| Type | Round/ Pan/ Hex Head/ Oval/ Truss head |

| Fasteners Standard: |

JIS, IS, ISO, BS, ANSI, DIN, GB, ASTM and all International Standards |

| Head | Pan head, flat head, oval head, hex head, phillips head |

| Head drive: | Slotted, Six-Lobe, Phillips/Slot, Phillips, etc |

| ASTM Standard | As Per ASTM A380M and A380 |

| Fasteners Manufacturing process | Cold Heading, Heat Treatment, Inspection, Wire Drawing, Packing, Surface Plating, Insert tapping |

| Manufacturers | GKW, SPAX® Screws, Kundan, Unbrako, Sundaram Precision, APL, EBY Fastener, Infasco Etc. |

| Certificate provided |

|

| industrial use of Fasteners | Wind tower, Electronic industry, Railway, Construction, Automotive industry, Nuclear power, |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| m3x0.5x8mm Long Allen Head Screw Titanium Fasteners, | 150 | 2.04 | 1.68 |

| Titanium Gr7 Fasteners M10 | 30,655 | 415.91 | 344.03 |

| m3x0.5x12mm Long Allen Head Screw Titanium Fasteners, | 193 | 2.62 | 2.17 |

| Din 933/934 Gr.2-m12 X 75 Bolt & Nut (200pcs) Titanium Fasteners | 5,852 | 79.40 | 65.67 |

| 20mm Satin Titanium Embossed Wing | 14,117 | 191.53 | 158.43 |

| Titanium Fasten (Exhibition Purpose) | 1,304 | 17.69 | 14.63 |

| Din 933/934 Gr.2-m16 X 75 Bolt & Nut(200pcs) Titanium Fasteners | 5,856 | 79.45 | 65.72 |

| (Alloy Ti-6a1-4v) M5x0.8x14mm Titanium Fasteners | 188 | 2.55 | 2.11 |

| M3x0.5x7mm Titanium Fasteners (Alloy Ti-6a1-4v) | 178 | 2.42 | 2.00 |

| M3x0.5x4mm Titanium Fasteners (Allloy Ti-6ai-4v) | 175 | 2.37 | 1.96 |

| HS Code | Description |

|---|---|

| 81089090 | (Allen Bolt +1 Nut+2 Washers) Titanium Gr7 Fasteners M10 |

| 81089090 | Titanium Fasteners (Exhibition Purpose) |

| 84213990 | Titanium Fasteners Included, Export Sea Crafting Included |

| 81089090 | Titanium Fasteners,m3x0.5x8mm Long Allen Head Screw |

| 81089090 | Titanium Fasteners (Alloy Ti-6a1-4v) M3x0.5x7mm |

| 91139090 | Folding Clasp, Push-piece Fastening, 20mm, Satin Titanium, Embossed Wing |

| 81089090 | Titanium Fasteners (Allloy Ti-6ai-4v) M3x0.5x4mm |

| 81089090 | Titanium Fasteners Din 933/934 Gr.2-m12 X 75 Bolt & Nut |

| 81089090 | Titanium Fasteners,m3x0.5x12mm Long Allen Head Screw |

| 91139090 | folding Clasp Push-piece Fastening 20mm Satin Titanium Embossed Wing |

| 91139090 | Folding Clasp Push-piece Fastening 20mm Satin Titanium Embossed Wing |

| 81089090 | Titanium Fasteners Din 933/934 Gr.2-m16 X 75 Bolt & Nut |

| 81089090 | Titanium Fasteners (Alloy Ti-6a1-4v) M5x0.8x14mm |

Therefore, titanium (6al4v) should be nearly impermeable to consumption and approximately 45 percent more grounded than steel. Would it really make a difference in terms of solidity if I were to redesign my steel equipment (screws, deadlocks, turn, and cut) using titanium instead of steel? If titanium is lighter than steel, I would assume that when people say it is "more grounded," they mean when comparing, say, 1 lb of titanium to 1 lb of steel. However, it would be expected that titanium screws of a comparable size would eventually replace the steel ones, so they wouldn't measure equally. In the event that titanium is just more grounded by precise weight, I'd envision you would require bigger titanium screws, stalemates, and so on to adjust in weight, and really make a distinction or advantage in strength.

Hexagon Nuts |

Stud Bolts |

Hexagon Bolts / Set Screws |

Socket Cap screws |

|---|---|---|---|

BS 1768 |

DIN 976 |

DIN 933 |

DIN 6912 |

DIN 934 |

BS4882 |

DIN 931 |

DIN 912 |

ISO 4033 |

ISO 4017 |

BS 2470 |

|

ANSI B18.2.2 |

BS 1769 |

BS 4168 |

|

BS 1083 |

UNI 5731 |

ANSI B18.3 |

|

BS 1769 |

BS 1768 |

DIN 7984 |

|

ISO 4032 |

ISO 4014 |

UNI 5931 |

|

BS 3692 |

UNI 5739 |

ISO 4762 |

|

BS 3692 |

|||

ANSI B18.2.1 |

Socket & Slotted Countersunk Screws |

Washers |

Socket & Slotted Set Screws |

Studs |

|---|---|---|---|

DIN 7991 |

DIN 9021 |

DIN 914 |

DIN 939 |

BS 483 |

DIN 551 |

BS 2693 |

|

DIN 963 |

DIN 125 |

DIN 913 |

DIN 938 |

BS 1981 |

BS 3410 |

DIN 916 |

BS 4439 |

BS 4168 |

BS 4320 |

DIN 915 |

DIN 2510 |

BS 2470 |

Spring Washers |

DIN 553 |

|

BS 4464 |

BS 4168 |

||

DIN 127 |

DIN 438 |

||

BS 1802 |

| Nominal Size, inch.0 | Fine Threads - UNF | Coarse Threads - UNC | 8 Thread Series - 8UN | |||

|---|---|---|---|---|---|---|

| Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | |

| 5/16 | 24 | 0.00580 | 18 | 0.00524 | -- | -- |

| 1/4 | 28 | 0.00364 | 20 | 0.00318 | -- | -- |

| 3/18 | 24 | 0.00878 | 16 | 0.00775 | -- | -- |

| 1/2 | 20 | 0.01599 | 13 | 0.01419 | ||

| 7/16 | 20 | 0.01187 | 14 | 0.01063 | ||

| 5/8 | 18 | 0.02560 | 11 | 0.02260 | ||

| 9/16 | 18 | 0.02030 | 12 | 0.01820 | ||

| 7/8 | 14 | 0.05090 | 9 | 0.04620 | ||

| 3/4 | 16 | 0.03730 | 10 | 0.03340 | ||

| 1 1/8 | 12 | 0.08560 | 7 | 0.07630 | 8 | 0.0790 |

| 1 | 12 | 0.06630 | 8 | 0.06060 | ||

| 1 3/8 | 12 | 1.03150 | 6 | 1.01550 | 8 | 1.0233 |

| 1 1/4 | 12 | 1.00730 | 7 | 0.09690 | 8 | 1.0000 |

| 1 1/2 | 12 | 1.05810 | 6 | 1.04050 | 8 | 1.049 |

FOR 100 NOS APPROX.0 WEIGHT IN Kilogram |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners SIZE | IS:6610 HEAVY WASHER |

IS:2016 PLAIN PUNCHED WASHER |

SQUARE TAPER WASHERS | SPRING WASHER FLAT SECTION IS:3063-72 | Size (Inches) | SPRING WASHER SQUARE SECTION IS:6735-72 DIN : 7980 |

PLAIN PUNCHED WASHER BS:3410 TABLE 7 |

|||

| MACHINED | HIGH STRENGTH FRICTION GRIP |

|||||||||

| FOR I-BEAM IS:5374-75 |

FOR CHANNELS IS:5372-75 |

TYPE-C ( I-BEAMS ) IS : 6649-85 |

TYPE-B (CHANNELS) IS : 6649-85 |

|||||||

| M3 | 0.0001 | 0.0001 | ||||||||

| M4 | 0.0002 | 0.0002 | ||||||||

| M5 | 0.0004 | 0.0003 | 0.0003 | |||||||

| M6 | 0.011 | 0.0008 | 1/4″ | 0.0004 | 0.021 | |||||

| M8 | 0.020 | 1.020 | 1.010 | 0.016 | 5/16″ | 0.011 | 0.035 | |||

| M10 | 1.060 | 0.039 | 1.010 | 1.000 | 0.025 | 3/8″ | 0.020 | 0.048 | ||

| M12 | 1.090 | 0.058 | 2.020 | 2.000 | 1.080 | 2.000 | 0.038 | 1/2″ | 0.023 | 1.007 |

| M14 | 0.082 | 0.060 | 0.038 | |||||||

| M16 | 2.090 | 1.006 | 3.075 | 3.040 | 8.050 | 9.000 | 0.089 | 5/8″ | 0.059 | 1.085 |

| M18 | 1.027 | 0.097 | 0.066 | |||||||

| M20 | 4.040 | 1.064 | 6.070 | 5.080 | 8.000 | 8.050 | 1.052 | 3/4″ | 1.023 | 2.091 |

| M22 | 1.075 | 7.000 | 7.050 | 1.065 | 7/8″ | 1.036 | 4.027 | |||

| M24 | 6.030 | 3.011 | 16.000 | 13.050 | 6.000 | 6.050 | 2.062 | 1″ | 1.081 | 6.013 |

| M27 | 8.000 | 3.094 | 15.000 | 12.050 | 11.050 | 12.000 | 2.087 | 1.01/8″ | 2.006 | 7.069 |

| M30 | 10.010 | 5.005 | 18.070 | 16.050 | 16.000 | 17.050 | 4.043 | 1.01/4″ | 3.020 | 9.090 |

| M33 | 12.000 | 7.010 | 23.050 | 21.000 | 22.050 | 23.000 | 6.030 | 3.050 | ||

| M36 | 14.060 | 8.073 | 29.020 | 25.050 | 26.000 | 26.050 | 6.073 | 1.01/2″ | 5.025 | 17.024 |

| M39 | 16.070 | 12.060 | 34.050 | 28.030 | 7.017 | 5.061 | ||||

| M42 | 20.010 | 17.050 | 11.010 | 8.000 | ||||||

| M45 | 22.020 | 21.020 | 11.070 | 8.053 | ||||||

| M48 | 26.000 | 28.040 | 12.030 | 2″ | 9.000 | 27.078 | ||||

| M52 | 31.090 | 18.020 | ||||||||

| M56 | 47.090 | 19.030 | ||||||||

| M60 | 51.060 | 20.030 | ||||||||

| M64 | 55.040 | 21.080 | ||||||||

| M68 | 57.040 | |||||||||

| M72 | 63.040 | 24.000 | ||||||||

Titanium Bolts Coatings |

|||||

|---|---|---|---|---|---|

Zinc Plating |

Hot Dipped Galvanizing |

Chrome Plating |

Teflon Coating |

Oxidized |

|

Epoxy Coating |

Passivation |

Mirror Buffed |

Electro Polished |

||

| AS PER IS 1363/67 MILLIMETER THREADS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| IN KILOGRAM FOR 100 NOS APPROXIMATE WEIGHT | ||||||||||

| LENGTH | DIAMETER | |||||||||

| M 6 | M 5 | M 10 | M 8 | M 14 | M 12 | M 18 | M 22 | M 16 | M 20 | |

| 16 millimeter | 0.743 | 0.448 | 3.211 | 1.590 | ||||||

| 20 millimeter | 0.812 | 0.598 | 3.411 | 1.711 | 4.892 | |||||

| 25 millimeter | 0.897 | 0.660 | 3.660 | 1.871 | 8.170 | 5.252 | ||||

| 30 millimeter | 1.010 | 0.737 | 3.912 | 2.070 | 9.690 | 5.574 | 10.707 | 18.657 | ||

| 35 millimeter | 1.120 | 0.804 | 4.223 | 2.271 | 10.000 | 5.974 | 16.026 | 11.416 | 19.608 | |

| 40 millimeter | 1.230 | 0.881 | 4.533 | 2.470 | 10.288 | 6.410 | 16.667 | 12.107 | 20.747 | |

| 45 millimeter | 1.340 | 0.958 | 4.840 | 2.671 | 10.504 | 6.859 | 17.241 | 12.821 | 21.739 | |

| 50 millimeter | 1.450 | 1.030 | 5.155 | 2.870 | 11.261 | 7.299 | 17.857 | 28.409 | 13.624 | 22.727 |

| 55 millimeter | 1.560 | 5.464 | 3.071 | 11.628 | 7.740 | 18.868 | 30.120 | 14.409 | 23.810 | |

| 60 millimeter | 1.670 | 5.774 | 3.270 | 12.255 | 8.183 | 20.000 | 32.051 | 15.244 | 25.126 | |

| 65 millimeter | 1.781 | 6.083 | 3.472 | 12.626 | 8.621 | 21.008 | 34.014 | 16.026 | 26.455 | |

| 70 millimeter | 1.890 | 6.394 | 3.671 | 12.987 | 9.058 | 22.124 | 35.461 | 16.835 | 27.778 | |

| 75 millimeter | 2.000 | 6.702 | 3.873 | 13.228 | 9.506 | 23.256 | 39.063 | 17.606 | 29.070 | |

| 80 millimeter | 2.111 | 7.013 | 4.072 | 13.889 | 10.000 | 24.510 | 40.000 | 18.248 | 30.303 | |

| 90 millimeter | 7.634 | 4.472 | 14.925 | 10.917 | 26.042 | 41.667 | 19.841 | 33.113 | ||

| 100 millimeter | 8.251 | 4.873 | 16.340 | 11.820 | 27.778 | 46.296 | 21.459 | 35.714 | ||

| 110 millimeter | 8.881 | 17.730 | 12.723 | 31.250 | 47.170 | 23.041 | 38.168 | |||

| 120 millimeter | 9.506 | 18.797 | 13.624 | 32.895 | 50.000 | 24.631 | 40.984 | |||

| 130 millimeter | 10.101 | 20.000 | 14.535 | 34.722 | 52.632 | 26.316 | 43.478 | |||

| 140 millimeter | 10.707 | 20.833 | 15.432 | 35.461 | 55.556 | 27.933 | 46.296 | |||

| 150 millimeter | 11.312 | 22.222 | 16.340 | 37.594 | 58.824 | 29.412 | 48.544 | |||

| 160 millimeter | 11.905 | 24.272 | 17.241 | 40.984 | 61.728 | 31.056 | 50.505 | |||

| 180 millimeter | 13.123 | 26.882 | 19.011 | 67.568 | 34.247 | 55.556 | ||||

| 170 millimeter | 12.500 | 18.116 | 64.935 | 32.680 | 53.191 | |||||

| 200 millimeter | 14.327 | 29.586 | 20.833 | 49.020 | 73.529 | 37.594 | 60.976 | |||

| 190 millimeter | 13.736 | 19.920 | 70.423 | 35.971 | 58.140 | |||||

| 240 millimeter | 16.722 | 24.510 | 84.746 | 43.860 | 71.429 | |||||

| 220 millimeter | 15.528 | 22.624 | 79.365 | 40.650 | 65.789 | |||||

| 260 millimeter | 17.921 | 26.316 | 90.909 | 47.170 | 76.923 | |||||

| 250 millimeter | 17.301 | 25.381 | 87.719 | 45.455 | 74.627 | |||||

| 300 millimeter | 20.325 | 29.940 | 104.167 | 53.763 | 87.719 | |||||

| 280 millimeter | 19.157 | 28.090 | 98.039 | 50.505 | 81.967 | |||||

| 340 millimeter | 33.557 | 60.241 | 98.039 | |||||||

| 320 millimeter | 31.646 | 56.818 | 92.593 | |||||||

| 380 millimeter | 37.037 | 66.667 | 108.696 | |||||||

| 360 millimeter | 35.211 | 63.291 | 104.167 | |||||||

| 400 millimeter | 39.063 | 69.444 | 113.636 | |||||||

| Size | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Inside Diameter (A) |

Thickness (C) |

Outside Diameter (B) |

Outside Diameter (B) |

Inside Diameter (A) |

Thickness (C) |

|

| #2 | 1/4" | 3/32" | 0.0020" | |||

| #4 | 5/16" | 1/8" | 0.0032" | |||

| #6 | 3/8" | 5/32" | 0.0049" | |||

| #8 | 7/16" | 3/16" | 0.0049" | |||

| #10 | 1/2" | 7/32" | 0.0049" | |||

| #12 | 9/16" | 1/4" | 0.0065" | |||

| 1/4" | 5/16" | 0.0065" | 0.0734" | 5/8" | 9/32" | 0.0065" |

| 5/16" | 3/8" | 0.0083" | 7/8" | 11/16" | 11/32" | 0.0065" |

| 3/8" | 7/16" | 0.0083" | 1" | 13/16" | 13/32" | 0.0065" |

| 7/16" | 1/2" | 0.0083" | 1-1/4" | 15/16" | 15/32" | 0.0065" |

| 1/2" | 9/16" | 0.0109" | 1-3/8" | 1-1/16" | 17/32" | 0.0095" |

| 9/16" | 5/8" | 0.0109" | 1-15/32" | 1-5/32" | 19/32" | 0.0095" |

| 5/8" | 11/16" | 0.0134" | 1-3/4" | 1-5/16" | 21/32" | 0.0095" |

| 3/4" | 13/16" | 0.0148" | 2" | 1-15/32" | 13/16" | 0.0134" |

| 7/8" | 15/16" | 0.0165" | 2-1/4" | 1-3/4" | 15/16" | 0.0134" |

| 1" | 1-1/16" | 0.0165" | 2-1/2" | 2" | 1-1/16" | 0.0134" |

| 1-1/8" | 1-1/4" | 0.0165" | 2-3/4" | |||

| 1-1/4" | 1-3/8" | 0.0165" | 3" | |||

| 1-3/8" | 1-1/2" | 0.0180" | 3-1/4" | |||

| 1-1/2" | 1-5/8" | 0.0180" | 3-1/2" | |||

| 1-5/8" | 1-3/4" | 0.0180" | 3-3/4" | |||

| 1-3/4" | 1-7/8" | 0.0180" | 4" | |||

| 2" | 2-1/8" | 0.0213" | 4-1/2" | |||

| Torque Specifications | |||||||

|---|---|---|---|---|---|---|---|

Bolt Size

Inches or # |

Threads

Per Inch |

Standard Dry Torque in Inch-Pounds

|

|||||

#2 |

56 |

2.05 |

2.06 |

||||

64 |

3.00 |

3.02 |

|||||

#3 |

48 |

3.09 |

4.00 |

||||

56 |

4.04 |

4.06 |

|||||

#4 |

40 |

5.02 |

5.05 |

||||

48 |

6.06 |

6.09 |

|||||

#5 |

40 |

7.07 |

8.01 |

||||

44 |

9.04 |

9.08 |

|||||

#6 |

32 |

9.06 |

10.01 |

||||

40 |

12.01 |

12.07 |

|||||

#8 |

32 |

19.08 |

20.07 |

||||

36 |

22.00 |

23.00 |

|||||

#10 |

24 |

22.08 |

23.08 |

||||

32 |

31.07 |

33.01 |

|||||

Bolt Size

Inches or # |

Threads

Per Inch |

Standard Dry Torque in Inch-Pounds

|

|||||

|---|---|---|---|---|---|---|---|

1/4 |

20 |

75.02 |

78.08 |

||||

28 |

94.00 |

99.00 |

|||||

5/16 |

18 |

132 |

138 |

||||

24 |

142 |

147 |

|||||

3/8 |

16 |

236 |

247 |

||||

24 |

259 |

271 |

|||||

7/16 |

14 |

376 |

393 |

||||

20 |

400 |

418 |

|||||

1/2 |

13 |

517 |

542 |

||||

20 |

541 |

565 |

|||||

Bolt Size

Inches or # |

Threads

Per Inch |

Standard Dry Torque in Inch-Pounds

|

|||||

|---|---|---|---|---|---|---|---|

9/16 |

12 |

682 |

713 |

||||

18 |

752 |

787 |

|||||

5/8 |

11 |

1110 |

1160 |

||||

18 |

1244 |

1301 |

|||||

3/4 |

10 |

1530 |

1582 |

||||

16 |

1490 |

1558 |

|||||

7/8 |

9 |

2328 |

2430 |

||||

14 |

2318 |

2420 |

|||||

1 |

8 |

3440 |

3595 |

||||

14 |

3110 |

3250 |

|||||

Bolt Size

Inches or # |

Threads

Per Inch |

Standard Dry Torque in Foot-Pounds

|

|||||

|---|---|---|---|---|---|---|---|

1 1/8 |

7 |

413 |

432 |

||||

12 |

390 |

408 |

|||||

1 1/4 |

7 |

523 |

546 |

||||

12 |

480 |

504 |

|||||

1 1/2 |

6 |

888 |

930 |

||||

12 |

703 |

732 |

|||||

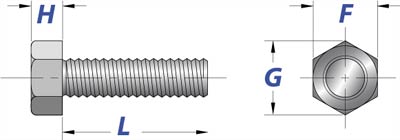

| Nominal Sizes | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats |

Width Across Corners |

Thickness | |||||||

| Basic | Minimum | Maximum | Minimum | Maximum | Basic | Maximum | Minimum | ||

| 1/4 | 0.02500 | 7/16 | 0.0428 | 0.0438 | 0.0488 | 0.0505 | 7/32 | 0.0226 | 0.0212 |

| 5/16 | 0.03125 | 1/2 | 0.0489 | 0.0500 | 0.0557 | 0.0577 | 17/64 | 0.0273 | 0.0258 |

| 7/16 | 0.04375 | 11/16 | 0.0675 | 0.0688 | 0.0768 | 0.0794 | 3/8 | 0.0385 | 0.0365 |

| 1/2 | 0.05000 | 3/4 | 0.0736 | 0.0750 | 0.0840 | 0.0866 | 7/16 | 0.0448 | 0.0427 |

| 5/8 | 0.06250 | 15/16 | 0.0922 | 0.0938 | 10.0051 | 10.0083 | 35/64 | 0.0559 | 0.0535 |

| 3/4 | 0.07500 | 1-1/8 | 10.0088 | 10.0125 | 10.0240 | 10.0299 | 41/64 | 0.0665 | 0.0617 |

| 7/8 | 0.08750 | 1-5/16 | 10.0269 | 10.0312 | 10.0447 | 10.0516 | 3/4 | 0.0776 | 0.0724 |

| 1-1/8 | 10.01250 | 1-11/16 | 10.0631 | 10.0688 | 10.0859 | 10.0949 | 31/32 | 0.0999 | 0.0939 |

| 1-3/8 | 10.03750 | 2-1/16 | 10.0994 | 20.0062 | 20.0273 | 20.0382 | 1-11/64 | 10.0206 | 10.0138 |

| 1-1/2 | 10.0500 | 2-1/4 | 20.0175 | 20.0250 | 20.0480 | 20.0598 | 1-9/32 | 10.0ASTM A194 GR0.0 8 | 10.0245 |

| 1-3/4 | 10.07500 | 2-5/8 | 20.0538 | 20.0625 | 20.0893 | 30.0031 | 1-1/2 | 10.0540 | 10.0460 |

| 2 | 20.00000 | 3 | 20.0900 | 30.0000 | 30.0306 | 30.0464 | 1-23/32 | 10.0763 | 10.0675 |

| 2-1/2 | 20.05000 | 3-3/4 | 30.0625 | 30.0750 | 40.0133 | 40.0330 | 2-5/32 | 20.0209 | 20.0105 |

| 2-3/4 | 20.07500 | 4-1/8 | 30.0988 | 40.0125 | 40.0546 | 40.0763 | 2-3/8 | 20.0431 | |

Nominal Size or Basic Major Thread Diameter |

G |

F |

H |

||||||

|---|---|---|---|---|---|---|---|---|---|

Width Across Corners |

Width Across Flats |

Thickness |

|||||||

Max |

Min |

Basic |

Max |

Min |

Basic |

Max |

Min |

||

0.02500 |

1/4 |

0.0577 |

0.0556 |

1/2 |

0.0500 |

0.0488 |

15/64 |

0.0250 |

0.0218 |

0.03125 |

5/16 |

0.0650 |

0.0622 |

9/16 |

0.0562 |

0.0546 |

19/64 |

0.0314 |

0.0280 |

0.03750 |

3/8 |

0.0794 |

0.0763 |

11/16 |

0.0688 |

0.0669 |

23/64 |

0.0377 |

0.0341 |

0.04375 |

7/16 |

0.0866 |

0.0830 |

3/4 |

0.0750 |

0.0728 |

27/64 |

0.0441 |

0.0403 |

0.05000 |

1/2 |

10.0010 |

0.0969 |

7/8 |

0.0875 |

0.0850 |

31/64 |

0.0504 |

0.0464 |

0.05625 |

9/16 |

10.0083 |

10.0037 |

15/16 |

0.0938 |

0.0909 |

35/64 |

0.0568 |

0.0526 |

0.06250 |

5/8 |

10.0227 |

10.0175 |

1-1/16 |

10.0062 |

10.0031 |

39/64 |

0.0631 |

0.0587 |

0.07500 |

3/4 |

10.0443 |

10.0382 |

1-1/4 |

10.0250 |

10.0212 |

47/64 |

0.0758 |

0.0710 |

0.08750 |

7/8 |

10.0660 |

10.0589 |

1-7/16 |

10.0438 |

10.0394 |

55/64 |

0.0885 |

0.0833 |

10.00000 |

1 |

10.0876 |

10.0796 |

1-5/8 |

10.0325 |

10.0575 |

63/64 |

10.0012 |

0.0956 |

10.01250 |

1-1/8 |

20.0093 |

20.0002 |

1-13/16 |

10.0812 |

10.0756 |

1-7/64 |

10.0139 |

10.0079 |

10.02500 |

1-1/4 |

20.0309 |

20.0209 |

2 |

20.0000 |

10.0938 |

1-7/32 |

10.0251 |

10.0187 |

10.03750 |

1-3/8 |

20.0526 |

20.0416 |

2-3/16 |

20.0188 |

20.0119 |

1-11/32 |

10.0378 |

10.0460 |

10.05000 |

1-1/2 |

20.0742 |

20.0622 |

2-3/8 |

20.0375 |

20.0300 |

1-15/32 |

10.0505 |

10.0433 |

10.06250 |

1-5/8 |

20.0959 |

20.0828 |

2-9/16 |

20.0562 |

20.0481 |

1-19/32 |

10.0632 |

10.0556 |

10.07500 |

1-3/4 |

30.0175 |

30.0035 |

2-3/4 |

20.0750 |

20.0662 |

1-23/32 |

10.0759 |

10.0679 |

20.00000 |

2 |

30.0608 |

30.0449 |

3-1/8 |

30.0125 |

30.0025 |

1-31/32 |

20.0013 |

10.0925 |

20.02500 |

2-1/4 |

40.0041 |

30.0862 |

3-1/2 |

30.0500 |

30.0388 |

2-13/64 |

20.0251 |

20.0155 |

20.05000 |

2-1/2 |

40.0474 |

40.0275 |

3-7/8 |

30.0875 |

30.0750 |

2-29/64 |

20.0505 |

20.0401 |

20.07500 |

2-3/4 |

40.0907 |

40.0688 |

4-1/4 |

40.0250 |

40.0112 |

2-45/64 |

20.0759 |

20.0647 |

30.00000 |

3 |

50.0340 |

50.0102 |

4-5/8 |

40.0625 |

40.0475 |

2-61/64 |

30.0013 |

20.0893 |

30.02500 |

3-1/4 |

50.0774 |

50.0515 |

5 |

50.0000 |

40.0838 |

3-3/16 |

30.0252 |

30.0124 |

30.05000 |

3-1/2 |

60.0207 |

50.0928 |

5-3/8 |

50.0375 |

50.0200 |

3-7/16 |

30.0506 |

30.0370 |

30.07500 |

3-3/4 |

60.0640 |

60.0341 |

5-3/4 |

50.0750 |

50.0562 |

3-11/16 |

30.0670 |

30.0616 |

40.00000 |

4 |

70.0073 |

60.0755 |

6-1/8 |

60.0125 |

50.0925 |

3-15/16 |

40.0014 |

30.0862 |

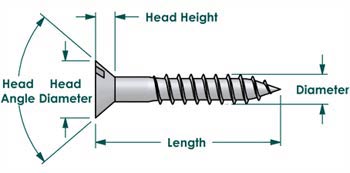

| Wood Screws: Slotted & Phillips Flat Head Dimensions (ASME B180.060.01) |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Phillips Driver Size |

Nominal Size* |

Head Diameter (A) |

Head Height (H) |

Width of Slot (J) |

Depth of Slot (T) |

Dimension of Recess |

|||||||

Maximum |

Minimum |

Ref |

Maximum |

Minimum |

Maximum |

Minimum |

Dia0.0 Minimum (M) |

Dia0.0 Maximum (M) |

Depth Minimum (G) |

Depth Maximum (G) |

Width Minimum (N) |

||

1 |

2 |

0.0172 |

0.0147 |

0.0051 |

0.0031 |

0.0023 |

0.0023 |

0.0015 |

0.0089 |

0.0102 |

0.0047 |

0.0063 |

0.0017 |

1 |

3 |

0.0199 |

0.0141 |

0.0059 |

0.0035 |

0.0027 |

0.0027 |

0.0017 |

0.0094 |

0.0107 |

0.0052 |

0.0068 |

0.0018 |

1 |

4 |

0.0225 |

0.0195 |

0.0067 |

0.0039 |

0.0031 |

0.0030 |

0.0020 |

0.0115 |

0.0128 |

0.0073 |

0.0089 |

0.0018 |

2 |

5 |

0.0252 |

0.0220 |

0.0075 |

0.0043 |

0.0035 |

0.0034 |

0.0022 |

0.0141 |

0.0154 |

0.0063 |

0.0086 |

0.0027 |

2 |

6 |

0.0279 |

0.0244 |

0.0083 |

0.0048 |

0.0039 |

0.0038 |

0.0024 |

0.0161 |

0.0174 |

0.0083 |

0.0106 |

0.0029 |

2 |

7 |

0.0305 |

0.0268 |

0.0091 |

0.0048 |

0.0039 |

0.0041 |

0.0027 |

0.0176 |

0.0189 |

0.0098 |

0.0121 |

0.0030 |

2 |

8 |

0.0332 |

0.0292 |

0.0100 |

0.0054 |

0.0045 |

0.0045 |

0.0029 |

0.0191 |

0.0204 |

0.0113 |

0.0136 |

0.0032 |

2 |

9 |

0.0358 |

0.0316 |

0.0108 |

0.0054 |

0.0045 |

0.0049 |

0.0032 |

0.0201 |

0.0214 |

0.0123 |

0.0146 |

0.0033 |

3 |

10 |

0.0385 |

0.0340 |

0.0116 |

0.0060 |

0.0050 |

0.0053 |

0.0034 |

0.0245 |

0.0258 |

0.0123 |

0.0146 |

0.0034 |

3 |

12 |

0.0438 |

0.0389 |

0.0132 |

0.0067 |

0.0056 |

0.0060 |

0.0039 |

0.0270 |

0.0283 |

0.0148 |

0.0171 |

0.0036 |

3 |

14 |

0.0507 |

0.0452 |

0.0153 |

0.0075 |

0.0064 |

0.0070 |

0.0046 |

0.0270 |

0.0283 |

0.0148 |

0.0171 |

0.0036 |

3 |

16 |

0.0544 |

0.0485 |

0.0164 |

0.0075 |

0.0064 |

0.0075 |

0.0049 |

0.0290 |

0.0303 |

0.0168 |

0.0191 |

0.0039 |

| NOMINIMUMAL SIZE (D) | HEAD THICKNESS | BODY DIAMETER | ACROSS CORNERS | |||

|---|---|---|---|---|---|---|

| H (MAXIMUM) | H (MINIMUM) | D (MAXIMUM) | D (MINIMUM) | C (MAXIMUM) | C (MINIMUM) | |

| m12 | 7.076 | 4.024 | 12.000 | 11.073 | 20.078 | 20.003 |

| m10 | 6.063 | 6.017 | 10.000 | 9.078 | 18.048 | 17.077 |

| m16 | 10.032 | 9.068 | 16.000 | 15.073 | 27.071 | 26.075 |

| m14 | 9.009 | 8.051 | 14.000 | 13.073 | 24.025 | 23.035 |

| m30 | 19.048 | 17.092 | 30.000 | 29.067 | 53.012 | 50.085 |

| m20 | 12.088 | 12.012 | 20.000 | 19.067 | 34.064 | 32.095 |

| m48 | 31.007 | 28.093 | 48.000 | 47.038 | 86.060 | 82.076 |

| m42 | 26.097 | 25.003 | 42.000 | 41.038 | 75.006 | 71.071 |

| m80 | 51.058 | 48.042 | 80.000 | 79.026 | 132.072 | 126.054 |

| m64 | 41.032 | 38.068 | 64.000 | 63.026 | 109.070 | 104.065 |

| m100 | 63.09 | 60.010 | 90.000 | 99.013 | 167.043 | 159.060 |

Nominal |

Hex Socket Size |

Thread.0 |

Body diameter and Head height |

Head Dia |

Soc.0 length |

||

|---|---|---|---|---|---|---|---|

Size |

Pitch |

Maximum |

Minimum |

Maximum |

Minimum |

||

J |

D /H |

A |

K |

||||

M3 |

2.050 |

0.05 |

3.000 |

2.086 |

5.050 |

5.020 |

1.03 |

M4 |

3.000 |

0.070 |

4.000 |

3.082 |

7.000 |

6.064 |

2.000 |

M5 |

4.000 |

0.08 |

5.000 |

4.082 |

8.050 |

8.014 |

2.070 |

M6 |

5.000 |

1.00 |

6.000 |

5.082 |

10.000 |

9.064 |

3.030 |

M8 |

6.000 |

1.025 |

8.000 |

7.078 |

13.000 |

12.057 |

4.03 |

M10 |

8.000 |

1.05 |

10.000 |

9.078 |

16.000 |

15.057 |

5.050 |

M12 |

10.000 |

1.075 |

12.000 |

11.073 |

18.000 |

17.057 |

6.060 |

M16 |

14.000 |

2.00 |

16.000 |

15.073 |

24.000 |

23.048 |

8.080 |

M20 |

17.000 |

2.05 |

20.000 |

19.067 |

30.000 |

29.048 |

10.070 |

M24 |

19.000 |

3.00 |

24.000 |

23.067 |

36.000 |

35.038 |

12.090 |

Nominal size |

Body Dia |

Hex Socket Size |

Thread Pitch |

Max Cone Dia |

Head Height |

Head Dia |

Soc.0 length |

||

|---|---|---|---|---|---|---|---|---|---|

D(min) |

D(max) |

J |

A1 |

H |

A_max |

A_Min |

K |

||

M3 |

2.086 |

3.000 |

2,0 |

0.05 |

6,72 |

1,86 |

6,00 |

5,82 |

1,05 |

M4 |

3.082 |

4.000 |

2,5 |

0.070 |

8,96 |

2,48 |

8,00 |

7,78 |

1,49 |

M5 |

4.082 |

5.000 |

3,0 |

0.08 |

11,2 |

3,1 |

10,00 |

9,78 |

1,86 |

M6 |

5.082 |

6.000 |

4,0 |

1.00 |

13,44 |

3,72 |

12,00 |

11,75 |

2,16 |

M8 |

7.078 |

8.000 |

5,0 |

1.025 |

17,92 |

4,96 |

16,00 |

15,73 |

2,85 |

M10 |

9.078 |

10.000 |

6,0 |

1.05 |

22,4 |

6,2 |

20,00 |

19,67 |

3,60 |

M12 |

11.073 |

12.000 |

8,0 |

1.075 |

26,88 |

7,44 |

24,00 |

23,67 |

4,35 |

M16 |

15.073 |

16.000 |

10,0 |

2.00 |

33,6 |

8,8 |

32,00 |

29,67 |

4,89 |

M20 |

19.067 |

20.000 |

10,0 |

2.05 |

40,32 |

10,16 |

40,00 |

35,61 |

5,49 |

|

Diameter*

(milimeter) |

Nut Size (milimeter) |

Height

(milimeter) |

||

|---|---|---|---|---|

|

Jam Nut |

Hex Nut |

Nylock Nut |

||

|

4 |

2 |

1.2 |

1.6 |

- |

|

5 |

2.5 |

1.6 |

2 |

- |

|

5.5 |

3 |

1.8 |

2.4 |

4 |

|

7 |

4 |

2.2 |

3.2 |

5 |

|

8 |

5 |

2.7 |

4 |

5 |

|

10 |

6 |

3.2 |

5 |

6 |

|

11 |

7 |

3.5 |

5.5 |

- |

|

13 |

8 |

4 |

6.5 |

8 |

|

17 |

10 |

5 |

8 |

10 |

|

19 |

12 |

6 |

10 |

12 |

|

22 |

14 |

7 |

11 |

14 |

|

24 |

16 |

8 |

13 |

16 |

|

27 |

18 |

9 |

15 |

18.5 |

|

30 |

20 |

10 |

16 |

20 |

|

* This is the diameter across the flats. It is also the size of wrench to use. |

||||

Titanium Acorn Nuts |

Titanium Dome Nuts |

Titanium Self Tapping Screws |

Titanium Lug Nuts |

Titanium Grub Screws |

Titanium Hex Head Screws |

Metric Titanium Bolts |

Titanium Flange Nuts |

Titanium Allen Bolts |

Titanium Allen Head Bolts |

ASTM B348 Titanium Tie Bar |

B348 Ti Threaded Rod |

Titanium Screws |

Titanium Set Screws |

Titanium Bolts Harley |

Thomson Titanium Bolts |

Titanium Crank Bolts |

Titanium M6 Bolts |