Mineral extraction is a procedure used in metallurgy to process ore once the ore has been separated from its precious mineral. Chemically aggressive solids and fluids are used in the extraction of ore.

This is why it's crucial that the equipment is constructed with a suitable material, like Hastelloy C276 bolts. Making a significant investment in ore processing machinery is analogous to choosing a corrosion-resistant material. What could be better than picking Hastelloy C276 stud bolts made of nickel? The Hastelloy c276 nuts are a popular choice in many ore processing plants because of their resistance to localised corrosion and pitting.

Thiosulfates are frequently present during the processing of different mineral ores, which causes microscopic holes or deformities in commonly used alloys. This is a significant issue with ore processing. Hastelloy c276 forged rings are the perfect material for ore processing machinery because to its resistance to corrosive chemical conditions. Leaching is a method of extracting ores that involves treating the ore with chemicals to change the valuable metals into soluble salts while impurities stay insoluble. The stud bolt in this equipment, ASTM B574 UNS N10276, is accustomed to taking part in an oxidative leaching procedure.

In fact, these Hastelloy c276 fasteners are suitable for usage in oxidising environments up to 1900°F. Additionally, Hastelloy C276 hex bolts often perform very well in high pressure situations. For instance, the ASTM B574 bolts work well at a pressure of roughly 5400 kPa during the acid leaching procedure. However, the DIN 2.4819 bolt is vulnerable to assault in situations that are highly oxidising.

Compare Hastelloy C276 Fasteners price with inconel 625 Fasteners price list

| Standard | IS, ANSI, ASTM DIN, ISO, JIS, GB, ASME, BS, UNI and all International Standards |

|---|---|

| Threads: | BSF, UNF METRIC, UNC, BSW or as required |

| Hastelloy C276 Bolts Standard | ANSI – American National Standards Institute

DIN:DIN 933, DIN 931, DIN 970, DIN 934 UTS – Unified Thread Standard : UNF, NPT, NPTF, UNS, UNC, UNEF ISO – International Organization for Standardization ISO 4033, : ISO 4032, JIS standards |

| Fasteners/ Bolts Size | M10, M4, M16, M36 M2.5, M6, M30, M12, M8, M14, M2, M3, M20, M24, M5 to M160 |

| Length | 3 mm to 200 mm |

| Head drive: | Phillips, Slotted, Phillips/Slot, Six-Lobe etc |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Hastelloy C276 Bolts Finishing | Zinc white, (yellow, black, blue), black oxide,

Dacroment, Geometry, plated zinc-nickel, anodizing, nickel plated, Stainless steel: Passivated Self-Colour, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, Stainless Steel, some special one like DACROMET and Mechanically Applied coating |

| raw materials of Source | JSPL, Usha Martin, Tata Steel, Mukund Steel, RINL, Dhamm Steel etc. |

| Hastelloy C276 Bolts Form | Square, Hex, Threading as per Gauge, Round Etc. |

| Process of Production | M2-M24: Cold Froging, hot forging M24-M100, machining and CNC for Customized connecting element |

| Hastelloy C276 Bolts Surface Coating |

|

| Packing | IN BULK: pallet, canton, carton / Small Boxs / pallet or customer request |

Sizes for Hastelloy C276 Hex Bolts range from M3 to M56. Always remember to request from your supplier that your Alloy C276 fasteners are in accordance with ASTM F467 / ASME SF467 and to verify that the external thread specifications should be ASME B1.1 2A/3A - 2B/3G Metric with a certificate NACE MR0103/MR0175/ISO 15156.

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Hastelloy C276 Hex Bolts -0.375 In X 1.5in Length | 253 | 3.42 | 2.87 |

| Hex Bolts Ft M2.5p X 100mm Din 933-hastelloy C-276 | 60 | 0.81 | 0.68 |

| Hex Bolts Ft M16-2.0p X 65mm Din 933- Hastelloy C-276 | 26 | 0.35 | 0.29 |

| hastelloy C276 hex Bolts With Nut M8x25mm L | 305 | 4.12 | 3.46 |

| Hastelloy Fasteners (Uns N010276) M10 X100mm (Hex Bolts + Hex Nut + Flat Washer) | 535 | 7.23 | 6.06 |

Hastelloy C276 Bolts

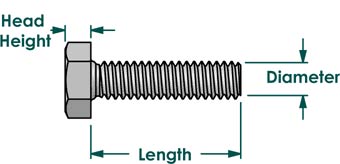

Size: 3/6" to 2" | M3 to M56 or Custom Sizes

| Hastelloy C276 Bolts NOMINAL SIZE (D) | Hastelloy C276 Bolts BODY DIAMETER | Hastelloy C276 Bolts HEAD THICKNE ASTM A479 | ACRO ASTM A479 THE FLATS | ACRO ASTM A479 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

DENSITY (G/CM 3) |

8.89 |

DENSITY (LB/IN 3) |

0.321 |

MELTING POINT (°C) |

1325 – 1370 |

MELTING POINT (°F) |

2415 – 2500 |

| Nominal Sizes | F | G | H | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats |

Width Across Corners |

Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | |

Hastelloy C276 Bolts Coating's |

|||||

|---|---|---|---|---|---|

|

Mirror Buffed

|

Hot Dipped Galvanizing

|

Epoxy Coating

|

Electro Polished

|

Passivation

|

|

|

Teflon Coating

|

Oxidized

|

Zinc Plating

|

Chrome Plating

|

||

Bolts Size |

USS |

SAE |

||||

|---|---|---|---|---|---|---|

Hastelloy C276 Bolts OD (in.) |

ID (in.) |

Hastelloy C276 Bolts Thickness |

OD (in.) |

Hastelloy C276 Bolts ID (in.) |

Hastelloy C276 Bolts Thickness |

|

1/8 (#6) |

0.375 |

0.156 |

.036/.065 |

|||

5/32 (#8) |

0.438 |

0.188 |

.036/.065 |

|||

3/16 (#10) |

0.560 |

0.250 |

.036/.065 |

0.500 |

0.220 |

.036/.065 |

7/32 (#12) |

0.562 |

0.250 |

.051/.080 |

|||

1/4 (#14) |

0.734 |

0.312 |

.051/.080 |

0.625 |

0.281 |

.051/.080 |

5/16 |

0.875 |

0.375 |

.064/.104 |

0.688 |

0.344 |

.051/.080 |

3/8 |

1.000 |

0.438 |

.064/.104 |

0.812 |

0.406 |

.051/.080 |

7/16 |

1.250 |

0.500 |

.064/.104 |

0.922 |

0.469 |

.051/.080 |

1/2 |

1.375 |

0.562 |

.086/.132 |

1.062 |

0.531 |

.074/.121 |

9/16 |

1.469 |

0.625 |

.086/.132 |

1.156 |

0.594 |

.074/.121 |

5/8 |

1.750 |

0.688 |

.108/.160 |

1.312 |

0.656 |

.074/.121 |

3/4 |

2.000 |

0.812 |

.122/.177 |

1.469 |

0.812 |

.108/.160 |

7/8 |

2.250 |

0.938 |

.136/.192 |

1.750 |

0.938 |

.108/.160 |

1 |

2.500 |

1.062 |

.136/.192 |

2.000 |

1.062 |

.108/.160 |

1 1/8 |

2.750 |

1.250 |

.136/.192 |

2.250 |

1.250 |

.108/.160 |

1 1/4 |

3.000 |

1.375 |

.136/.192 |

2.500 |

1.375 |

.136/.192 |

1 3/8 |

3.250 |

1.500 |

.153/.213 |

2.750 |

1.500 |

.136/.213 |

1 1/2 |

3.500 |

1.625 |

.153/.213 |

3.000 |

1.625 |

.153/.213 |

1 5/8 |

3.750 |

1.750 |

.153/.213 |

|||

1 3/4 |

4.000 |

1.875 |

.153/.213 |

|||

1 7/8 |

4.250 |

2.000 |

.153/.213 |

|||

2 |

4.500 |

2.125 |

.153/.213 |

|||

2 1/4 |

4.750 |

2.375 |

.320/.248 |

|||

2 1/2 |

5.000 |

2.625 |

.210/.280 |

|||

2 3/4 |

5.250 |

2.875 |

.228/.410S |

|||

3 |

5.500 |

3.125 |

.249/.327 |

|||

| Nominal | Thread. | Hex Socket Size | Body diameter and Head height | Head Dia | Soc. length | ||

|---|---|---|---|---|---|---|---|

| Size | Pitch | Max | Min | Max | Min | ||

| J | D /H | A | K | ||||

| M3 | 0.5 | 2.50 | 3.00 | 2.86 | 5.50 | 5.20 | 1.3 |

| M4 | 0.70 | 3.00 | 4.00 | 3.82 | 7.00 | 6.64 | 2.00 |

| M5 | 0.8 | 4.00 | 5.00 | 4.82 | 8.50 | 8.14 | 2.70 |

| M6 | 1.0 | 5.00 | 6.00 | 5.82 | 10.00 | 9.64 | 3.30 |

| M8 | 1.25 | 6.00 | 8.00 | 7.78 | 13.00 | 12.57 | 4.3 |

| M10 | 1.5 | 8.00 | 10.00 | 9.78 | 16.00 | 15.57 | 5.50 |

| M12 | 1.75 | 10.00 | 12.00 | 11.73 | 18.00 | 17.57 | 6.60 |

| M16 | 2.0 | 14.00 | 16.00 | 15.73 | 24.00 | 23.48 | 8.80 |

| M20 | 2.5 | 17.00 | 20.00 | 19.67 | 30.00 | 29.48 | 10.70 |

| M24 | 3.0 | 19.00 | 24.00 | 23.67 | 36.00 | 35.38 | 12.90 |

| Hastelloy Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

|

||

| Hastelloy Bolts | Hex Head Bolts, Shoulder Bolts, Wedge Anchor Bolts | • DIN 931 • DIN 933 • ISO 4014 • ISO 4017 • ISO 7370 |

||

| Hastelloy Nuts | Hex Nuts, Lock Nuts | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 985 / ISO 7040 • DIN 986 • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 |

||

| Hastelloy Studs/Rod | Studs, Threaded Rod, Weld Studs | • DIN 975 • DIN 976 |

||

| Hastelloy Washers | Flat Washers, Lock Washer | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 127 / ISO 7090 • DIN 9021 / ISO 7093 |

||

| Hastelloy Hose Clamps | Medium Duty Hose Clamps |

| Size | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

|

| #2 | 3/32" | 1/4" | 0.020" | |||

| #4 | 1/8" | 5/16" | 0.032" | |||

| #6 | 5/32" | 3/8" | 0.049" | |||

| #8 | 3/16" | 7/16" | 0.049" | |||

| #10 | 7/32" | 1/2" | 0.049" | |||

| #12 | 1/4" | 9/16" | 0.065" | |||

| 1/4" | 5/16" | 0.734" | 0.065" | 9/32" | 5/8" | 0.065" |

| 5/16" | 3/8" | 7/8" | 0.083" | 11/32" | 11/16" | 0.065" |

| 3/8" | 7/16" | 1" | 0.083" | 13/32" | 13/16" | 0.065" |

| 7/16" | 1/2" | 1-1/4" | 0.083" | 15/32" | 15/16" | 0.065" |

| 1/2" | 9/16" | 1-3/8" | 0.109" | 17/32" | 1-1/16" | 0.095" |

| 9/16" | 5/8" | 1-15/32" | 0.109" | 19/32" | 1-5/32" | 0.095" |

| 5/8" | 11/16" | 1-3/4" | 0.134" | 21/32" | 1-5/16" | 0.095" |

| 3/4" | 13/16" | 2" | 0.148" | 13/16" | 1-15/32" | 0.134" |

| 7/8" | 15/16" | 2-1/4" | 0.165" | 15/16" | 1-3/4" | 0.134" |

| 1" | 1-1/16" | 2-1/2" | 0.165" | 1-1/16" | 2" | 0.134" |

| 1-1/8" | 1-1/4" | 2-3/4" | 0.165" | |||

| 1-1/4" | 1-3/8" | 3" | 0.165" | |||

| 1-3/8" | 1-1/2" | 3-1/4" | 0.180" | |||

| 1-1/2" | 1-5/8" | 3-1/2" | 0.180" | |||

| 1-5/8" | 1-3/4" | 3-3/4" | 0.180" | |||

| 1-3/4" | 1-7/8" | 4" | 0.180" | |||

| 2" | 2-1/8" | 4-1/2" | 0.213" | |||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grade |

Ni |

C |

Mo |

Mn |

Si |

Fe |

P |

S |

Co |

Cr |

|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C276 Bolts | Balance |

0.01 max |

15 – 17 |

1.0 max |

0.08 max |

4 – 7 |

0.04 max |

0.03 max |

2.5 max |

14.5 – 16.5 |

Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

|---|---|---|---|---|

8.89 g/cm3 |

1370 °C (2500 °F) |

Psi – 52,000 , MPa – 355 |

Psi – 1,15,000 , MPa – 790 |

40 % |

STANDARD |

UNS |

WERKSTOFF NR. |

AFNOR |

EN |

JIS |

OR |

GOST |

|---|---|---|---|---|---|---|---|

Hastelloy C276 Bolts |

N10276 |

2.4819 |

– |

NiMo16Cr15W |

NW 0276 |

ЭП760 |

ХН65МВУ |

Different material grades are used to create the bolts and nuts. The 304 grade is the most often utilised, followed by the 316 grade. Bolts of the C276 grade are uncommon. The C276 hex bolts are utilised in operations that are very susceptible to corrosion at high temperatures. The 316 hex head bolts are used to combat both chloride iron corrosion and general corrosion. Food grade applications, marine and sea water applications, water lines, and other generally corrosive applications can all use 316 hex head bolts. Compared to C276 alloy hex bolts, these are less expensive. The majority of applications for c276 hex bolts are in chemical processing. They do not corrode easily under severe conditions such as concentrated acids, alkalis and in heat exchangers at very high temperatures as well.

| 1⁄2“ Nut | 3.75 | 6.54 | 2.62 | 4.00 | 5.78 | 7.87 |

| 5⁄8“ Nut | 7.33 | 11.9 | 4.93 | 6.96 | 10.8 | 14.3 |

| 3⁄4“ Nut | 11.9 | 19.3 | 7.70 | 11.0 | 15.4 | 23.5 |

| 7⁄8“ Nut | 19.0 | 29.7 | 12.0 | 16.7 | 24.5 | 36.2 |

| 1″ Nut | 28.3 | 42.5 | 17.6 | 23.5 | 36.3 | 51.5 |

| 11⁄8“ Nut | 40.3 | 59.2 | 24.7 | 32.4 | 52.5 | 72.4 |

| 11⁄4“ Nut | 54.3 | 78.6 | 36.1 | 45.8 | 70.6 | 95.5 |

| 13⁄8“ Nut | 73.0 | 102 | 47.9 | 59.3 | 94.5 | 125.0 |

| 11⁄2“ Nut | 94.3 | 131 | 60.9 | 74.8 | 122 | 161 |

| 15⁄8“ Nut | 162 | 91.6 | ||||

| 13⁄4“ Nut | 151 | 204 | 100 | 114 | ||

| 17⁄8“ Nut | 241 | 134 | ||||

| 2″ Nut | 224 | 299 | 140 | 165 | ||

| 21⁄4“ Nut | 419 | 227 | ||||

| 21⁄2“ Nut | 564 | 332 | ||||

| 23⁄4“ Nut | 738 | 429 | ||||

| 3″ Nut | 950 | 545 | ||||

| 31⁄4“ Nut | 1194 | 651 | ||||

| 31⁄2“ Nut | 1526 | 851 | ||||

| 33⁄4“ Nut | 1812 | 1005 | ||||

| 4″ Nut | 2180 | 1200 |

MM THREADS AS PER IS 1363/67 |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Hastelloy C276 Bolts APPROXIMATE WEIGHT IN KGS FOR 100 NOS |

||||||||||

LENGTH |

D I A M E T E R |

|||||||||

M 5 |

M 6 |

M 8 |

M 10 |

M 12 |

M 14 |

M 16 |

M 18 |

M 20 |

M 22 |

|

| 16 mm | 0.448 | 0.743 | 1.590 | 3.211 | ||||||

| 20 mm | 0.598 | 0.812 | 1.711 | 3.411 | 4.892 | |||||

| 25 mm | 0.660 | 0.897 | 1.871 | 3.660 | 5.252 | 8.170 | ||||

| 30 mm | 0.737 | 1.010 | 2.070 | 3.912 | 5.574 | 9.690 | 10.707 | 18.657 | ||

| 35 mm | 0.804 | 1.120 | 2.271 | 4.223 | 5.974 | 10.000 | 11.416 | 16.026 | 19.608 | |

| 40 mm | 0.881 | 1.230 | 2.470 | 4.533 | 6.410 | 10.288 | 12.107 | 16.667 | 20.747 | |

| 45 mm | 0.958 | 1.340 | 2.671 | 4.840 | 6.859 | 10.504 | 12.821 | 17.241 | 21.739 | |

| 50 mm | 1.030 | 1.450 | 2.870 | 5.155 | 7.299 | 11.261 | 13.624 | 17.857 | 22.727 | 28.409 |

| 55 mm | 1.560 | 3.071 | 5.464 | 7.740 | 11.628 | 14.409 | 18.868 | 23.810 | 30.120 | |

| 60 mm | 1.670 | 3.270 | 5.774 | 8.183 | 12.255 | 15.244 | 20.000 | 25.126 | 32.051 | |

| 65 mm | 1.781 | 3.472 | 6.083 | 8.621 | 12.626 | 16.026 | 21.008 | 26.455 | 34.014 | |

| 70 mm | 1.890 | 3.671 | 6.394 | 9.058 | 12.987 | 16.835 | 22.124 | 27.778 | 35.461 | |

| 75 mm | 2.000 | 3.873 | 6.702 | 9.506 | 13.228 | 17.606 | 23.256 | 29.070 | 39.063 | |

| 80 mm | 2.111 | 4.072 | 7.013 | 10.000 | 13.889 | 18.248 | 24.510 | 30.303 | 40.000 | |

| 90 mm | 4.472 | 7.634 | 10.917 | 14.925 | 19.841 | 26.042 | 33.113 | 41.667 | ||

| 100 mm | 4.873 | 8.251 | 11.820 | 16.340 | 21.459 | 27.778 | 35.714 | 46.296 | ||

| 110 mm | 8.881 | 12.723 | 17.730 | 23.041 | 31.250 | 38.168 | 47.170 | |||

| 120 mm | 9.506 | 13.624 | 18.797 | 24.631 | 32.895 | 40.984 | 50.000 | |||

| 130 mm | 10.101 | 14.535 | 20.000 | 26.316 | 34.722 | 43.478 | 52.632 | |||

| 140 mm | 10.707 | 15.432 | 20.833 | 27.933 | 35.461 | 46.296 | 55.556 | |||

| 150 mm | 11.312 | 16.340 | 22.222 | 29.412 | 37.594 | 48.544 | 58.824 | |||

| 160 mm | 11.905 | 17.241 | 24.272 | 31.056 | 40.984 | 50.505 | 61.728 | |||

| 170 mm | 12.500 | 18.116 | 32.680 | 53.191 | 64.935 | |||||

| 180 mm | 13.123 | 19.011 | 26.882 | 34.247 | 55.556 | 67.568 | ||||

| 190 mm | 13.736 | 19.920 | 35.971 | 58.140 | 70.423 | |||||

| 200 mm | 14.327 | 20.833 | 29.586 | 37.594 | 49.020 | 60.976 | 73.529 | |||

| 220 mm | 15.528 | 22.624 | 40.650 | 65.789 | 79.365 | |||||

| 240 mm | 16.722 | 24.510 | 43.860 | 71.429 | 84.746 | |||||

| 250 mm | 17.301 | 25.381 | 45.455 | 74.627 | 87.719 | |||||

| 260 mm | 17.921 | 26.316 | 47.170 | 76.923 | 90.909 | |||||

| 280 mm | 19.157 | 28.090 | 50.505 | 81.967 | 98.039 | |||||

| 300 mm | 20.325 | 29.940 | 53.763 | 87.719 | 104.167 | |||||

| 320 mm | 31.646 | 56.818 | 92.593 | |||||||

| 340 mm | 33.557 | 60.241 | 98.039 | |||||||

| 360 mm | 35.211 | 63.291 | 104.167 | |||||||

| 380 mm | 37.037 | 66.667 | 108.696 | |||||||

| 400 mm | 39.063 | 69.444 | 113.636 | |||||||

| ASTM B574 Hastelloy C276 Lock Washer | Hastelloy WERKSTOFF NR. 2.4819 Self drilling screws |

| EN 2.4819 Hastelloy C276 Nuts and Bolts | ASTM B574 Hastelloy N10276 StudBolts |

| ASTM B574 Hastelloy C276 Dowel Pin | Hastelloy C276 Tie Bar |

| Hastelloy C276 Double Ended Stud | GOST ХН65МВУ Hastelloy Pan Head Screw |

| Hastelloy C276 Flat Washer | Hastelloy C276 Coupler Nuts |

| Hastelloy C276 Foundation Bolts | Hastelloy C276 Washers |

| Hastelloy C276 Punched Washer | ASTM B574 Hastelloy C276 Lock Nut |

| ASTM B574 Hastelloy C276 Nuts | Hastelloy C276 Square Nut |

| Hastelloy WERKSTOFF NR. 2.4819 Self-tapping Bolts | DIN 2.4819 Hastelloy Hex Head Bolts |

| ASTM B574 Hastelloy C276 Bolts | Hastelloy C276 Blind fasteners |

| UNS N10276 Hastelloy Threaded Rod | Hastelloy N10276 Insert Nuts |

| Hastelloy 2.4819 Industrial fasteners and fixings | Hastelloy C276 Fender Washer |

| Hastelloy C276 Welding Studs | ASTM B574 Hastelloy N10276 Pan Head Screw |

| WERKSTOFF NR. 2.4819 Hastelloy Square Bolts | Hastelloy C276 Hex Bolts |

| Hastelloy 2.4819 Stud Bolts | ASTM B574 Hastelloy C276 Locking Nuts |

| Hastelloy C276 Cap Screw | ASTM B574 Hastelloy C276 Pins and keys |

| Hastelloy C276 Self Clinching Fasteners | JIS NW 0276 Hastelloy Countersunk Slotted Screw |