Stainless steel bars are used often in a wide variety of engineering applications. The SS 304 Square Bar is still one of the most economically viable options, being used both in general assembly and as manufacturing components. Alloy 304 is one of numerous stainless steel grades that offers fairly high strength and moderately good corrosion resistance. The price of the bar is lower than many molybdenum bearing alloys because grade 304 8mm stainless steel hollow square bar has an alloying concentration of 18% chromium and 8% nickel. one of the biggest manufacturers of SS square bars

The manufacturer can advise utilising an SS 316 Square Bar, which is the next best option, in applications where stronger strength and higher corrosion resistant qualities are required. Any Stainless Steel Square Bar Manufacturer In India will tell you that the majority of their orders are for ornamental or decorative uses, railings, safety window barriers, or even gates.

The polished stainless steel square bar's ability to have a gloss that gives the bars a shiny surface—which is good for decorative purposes—is what makes them so ideal. Depending on the needs of the final application, the finishing could potentially have a mirror effect. In compared to hot finished square bar, cold finished square bar typically has a better finish, and the component's edges have more definition. The Hot Finished Square Bar, on the other hand, uses heat, which reduces processing time. As a result, processing costs decrease.

before buy Compare Stainless Steel Square Bar price with inconel 625 round bar price list

The multipurpose steel region known as square bars, also known as square steel, squares, and square metal bar, is mostly used for assembly and repairs. Our light and removed part is crucial for universally helpful square bars, making it appropriate for routine business ventures.

The multipurpose steel region known as square bars, also known as square steel, squares, and square metal bar, is mostly used for assembly and repairs. Our light and removed part is crucial for universally helpful square bars, making it appropriate for routine business ventures.

Width X Depth |

Width X Depth |

Width X Depth |

|---|---|---|

milimeter |

milimeter |

milimeter |

20X20 |

5X5 |

48X48 |

19X19 |

4X4 |

45X45 |

22X22 |

7X7 |

53X53 |

21X21 |

6X6 |

50X50 |

25X25 |

9X9 |

60X60 |

24X24 |

8X8 |

56X56 |

28X28 |

11X11 |

67X67 |

26X26 |

10X10 |

63X63 |

32X32 |

13X13 |

75X75 |

30X30 |

12X12 |

70X70 |

35X35 |

15X15 |

85X85 |

34X34 |

14X14 |

80X80 |

40X40 |

17X17 |

95X95 |

38X38 |

16X16 |

90X90 |

42X42 |

18X18 |

100X100 |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Eras-12 Friction Stay -18mm Square Groove, 2 Bar 2.5mm Thickness, With Plastic Slider | 188 | 2.54 | 2.09 |

| 80cm Stainless Steel Long Bar And Square Shower Head | 104 | 1.41 | 1.16 |

| Stainless Steel Square Bar-410s | 401 | 5.42 | 4.46 |

| Stainless Steel 310s Square Bar 50/50 (Lg=1500mm) | 155,560 | 2101.63 | 1729.00 |

| Stainless Steel Square Bar Steel 140., S235jr | 650 | 8.78 | 7.22 |

| Sunrise Hydraulic Ironworkers Iw-60s Without Round/square Bar Shear Tool | 544,745 | 7359.56 | 6054.68 |

| Uns S20910 - 40 X 40 Mm Stainless Steel Bar - Square Bar, Xm19, | 751 | 10.15 | 8.35 |

| Paddlewheel Aerator Scd-1.5 ( 2 Hp 230v 50hz Single Phase With Float Without Square Pipe S.s Solid Shaft&setting Bar | 18,042 | 243.75 | 200.53 |

| Sunrise Hydraulic Ironworker Iw-50a S/l No 15120242without Round Square Bar Shearing Tool | 397,919 | 5375.93 | 4422.75 |

| Size:20mm X 20mm X 4040mm Stainless Steel Hot Rolled Square Bar Grade:s45c | 135 | 1.82 | 1.50 |

| Size:20mm X 20mm X 4040mm Stainless Steel Hot Rolled Square Bar Grade:s45c | 135 | 1.82 | 1.50 |

| Stainless Steel Square Bar 14 L.40 For Crushing Machines | 192 | 2.59 | 2.13 |

| Stainless Steel Square Bar Size and Theoretical Weight | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (kilogram/m) | Size (milimeter) | Weight (kilogram/m) | Size (milimeter) | Weight (kilogram/m) | Size (milimeter) | Weight (kilogram/m) | Size (milimeter) | ||||

| 0.0071 | 3 × 3 | 1.0784 | 15 × 15 | 7.0137 | 30 × 30 | 28.0548 | 60 × 60 | ||||

| 0.0127 | 4 × 4 | 2.003 | 16 × 16 | 8.012 | 32 × 32 | 31.0474 | 63 × 63 | ||||

| 0.0198 | 5 × 5 | 2.0292 | 17 × 17 | 9.0167 | 34 × 34 | 35.0598 | 67 × 67 | ||||

| 0.0285 | 6 × 6 | 2.0569 | 18 × 18 | 9.0714 | 35 × 35 | 38.0857 | 70 × 70 | ||||

| 0.0389 | 7 × 7 | 2.0863 | 19 × 19 | 11.0451 | 38 × 38 | 44.0606 | 75 × 75 | ||||

| 0.0508 | 8 × 8 | 3.0172 | 20 × 20 | 12.0688 | 40 × 40 | 50.0752 | 80 × 80 | ||||

| 0.0642 | 9 × 9 | 3.0497 | 21 × 21 | 13.0989 | 42 × 42 | 52.0294 | 85 × 85 | ||||

| 0.0793 | 10 × 10 | 3.0838 | 22 × 22 | 16.0058 | 45 × 45 | 64.0233 | 90 × 90 | ||||

| 0.096 | 11 × 11 | 4.0568 | 24 × 24 | 18.0271 | 48 × 48 | 71.0568 | 95 × 95 | ||||

| 1.0142 | 12 × 12 | 4.0956 | 25 × 25 | 19.0825 | 50 × 50 | 79.03 | 100 × 100 | ||||

| 1.034 | 13 × 13 | 5.0361 | 26 × 26 | 22.0275 | 53 × 53 | ||||||

| 1.0554 | 14 × 14 | 6.0217 | 28 × 28 | 24.0868 | 56 × 56 | ||||||

| Siding × Siding × 0.000793 = Weight (kg) per meter | |||||||||||

the Stainless Steel square bar is that strong steel bar made of steel ingots through squeezing, anyway the very unique square tube is empty segment with cycle of welding the pipe's billets.

| Bright drawn | BD | Slit rolled edge | SRE |

| Cold drawn | CD | Polished | P |

| Peeled and turned | P&T | Rough turned/peeled | RT |

| Cold finished | CF | Hot rolled pickled and annealed | HRAP |

| Centreless ground | CG | Hot finished | HF |

| Smooth turned | ST | reeled and Peeled | PR |

Stainless Steel CF Tolerances |

Minus |

Plus |

|---|---|---|

5/16″ to 1/2″ (exclusive) |

0.003 |

0.000 |

1/8″ to 5/16″ (exclusive) |

0.002 |

0.000 |

over 1″ to 2″ (inclusive) |

0.006 |

0.000 |

1/2″ to 1″ (inclusive) |

0.004 |

0.000 |

over 2″ to 3″ (inclusive) |

0.008 |

0.000 |

Stainless Steel Cold Finished Square Bar Straightness Tolerance:

CF: 1/16 inch in any 5 foot; but may not exceed 1/16 X (length in ft/5)

Stainless Steel HF Tolerances |

Minus |

Plus |

Out of Sq |

|---|---|---|---|

Over 1″ to 1-1/8″ (inclusive) |

0.010 |

0.010 |

0.015 |

Over 1-1/2″ to 2″ (inclusive) |

1/64 |

1/64 |

0.023 |

Over 1-1/4″ to 1-3/8″ (inclusive) |

0.012 |

0.012 |

0.018 |

Over 1-1/8″ to 1-1/4″ (inclusive) |

0.011 |

0.011 |

0.016 |

Over 1-3/8″ to 1-1/2″ (inclusive) |

0.014 |

0.014 |

0.021 |

Stainless Steel Hot Finished Square Bar Straightness Tolerance:

HF: 1/8 inch in any 5 foot; but may not exceed 1/8 X (length in ft/5)

| ANN | Annealed |

| H&T | Hardened and tempered. |

| PH | Precipitation hardened. |

| Stainless Steel Grade | Mn | C | Fe | P | Si | S | Mo | Ti | Cr | N | Ni | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stainless Steel 304 | minimum | 18.00 | 8.00 | |||||||||

| maximum | 2.00 | 0.008 | 0.0045 | 0.075 | 0.0030 | 20.00 | 0.010 | 10.05 | ||||

| 304L | minimum | 18.00 | 8.00 | |||||||||

| maximum | 2.00 | 0.0030 | 0.0045 | 0.075 | 0.0030 | 20.00 | 0.010 | 12.00 | ||||

| 304H | minimum | 0.004 | 18.00 | 8.00 | ||||||||

| maximum | 2.00 | 0.0010 | 0.0045 | 0.075 | 0.0030 | 20.00 | 10.05 | |||||

| Stainless Steel 310 | 2 maximum | 0.0015 maximum | 0.0020 maximum | 0.0015 maximum | 0.0015 maximum | 0.010 maximum | 24.000 26.000 | 54.07 minimum | 19.000 21.000 | |||

| SS 310S | 2 maximum | 0.008 maximum | 0.0045 maximum | 1.000 maximum | 0.0030 maximum | 0.075 maximum | 24.000 26.000 | 53.0095 minimum | 19.000 21.000 | |||

| Stainless Steel 310H | 2 maximum | 0.004 0.010 | 0.0045 maximum | 1.000 maximum | 0.0030 maximum | 24.000 26.000 | 53.0885 minimum | 19.000 21.000 | ||||

| Stainless Steel 316 | minimum | 2.003.00 | 16.00 | 10.00 | ||||||||

| maximum | 2.00 | 0.0035 | 0.0045 | 0.075 | 0.0030 | 18.00 | 14.00 | |||||

| 316L | minimum | 2.003.00 | 16.00 | 10.00 | ||||||||

| maximum | 2.00 | 0.0035 | 0.0045 | 0.075 | 0.0030 | 18.00 | 14.00 | |||||

| 316TI | 10.000 14.000 | 0.008 maximum | 0.0045 maximum | 2.00 maximum | 0.0030 maximum | 0.075 maximum | 16.000 18.000 | 2.000 3.000 | ||||

| Stainless Steel 317 | 2 maximum | 0.008 maximum | 57.0845 minimum | 0.0045 maximum | 1 maximum | 0.0030 maximum | 3.000 4.000 | 18.000 20.000 | ||||

| SS 317L | 2.00 maximum | 0.0035 maximum | 57.089 minimum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 3.000 4.000 | 18.000 20.000 | 11.000 15.000 | |||

| SS 321 | 2.00 maximum | 0.008 maximum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 5(C+N) 0.070 maximum | 17.000 19.000 | 0.010 maximum | 9.000 12.000 | |||

| Stainless Steel 321H | 2.00 maximum | 0.004 0.010 | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 4(C+N) 0.070 maximum | 17.000 19.000 | 0.010 maximum | 9.000 12.000 | |||

| 347/ 347H | 2.00 maximum | 0.008 maximum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 17.000 20.000 | 9.00013.000 | |||||

| Stainless Steel 410 | minimum | 11.05 | ||||||||||

| maximum | 1.00 | 0.015 | 0.0040 | 1.000 | 0.0030 | 13.05 | 0.075 | |||||

| 446 | minimum | 23.00 | 0.010 | |||||||||

| maximum | 1.05 | 0.02 | 0.0040 | 0.075 | 0.0030 | 30.00 | 0.025 | 0.050 | ||||

| Stainless Steel 904L | minimum | 4.000 | 19.00 | 0.010 | 23.000 | |||||||

| maximum | 2.000 | 0.020 | 0.0045 | 1.000 | 0.0035 | 5.000 | 23.00 | 0.025 | 28.000 | |||

| Stainless Steel Grade | Density | Tensile Strength | Elongation | Melting Point | Yield Strength |

|---|---|---|---|---|---|

| 304H | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 40 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| Stainless Steel 304/ 304L | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| 904L | 7.95 g/centimeter3 | MPa 490, Psi 71000 | 35 % | (2460 °F) 1350 °C | MPa 220, Psi 32000 |

| 306/ 316H | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| Stainless Steel 310 / 310S / 310H | 7.9 g/centimeter3 | MPa 515, Psi 75000 | 40 % | (2555 °F) 1402 °C | MPa 205, Psi 30000 |

| 316L | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1399 °C | MPa 205, Psi 30000 |

| Stainless Steel 321 | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2650 °F) 1457 °C | MPa 205, Psi 30000 |

| 317 | 7.9 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F)1400 °C | MPa 205, Psi 30000 |

| 347 | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2650 °F) 1454 °C | MPa 205, Psi 3000 |

| STANDARD | AFNOR | UNS | WERKSTOFF NR. | JIS | GOST | BS | EN |

|---|---|---|---|---|---|---|---|

| Stainless Steel 304L | Z3CN18‐10 | S30403 | 1.4306 / 1.4307 | SUS 304L | 03Х18Н11 | 3304S11 | X2CrNi18-9 / X2CrNi19-11 |

| SS 310 | – | S31000 | 1.4841 | SUS 310 | 20Ch25N20S2 | 310S24 | X15CrNi25-20 |

| SS 304H | – | S30409 | 1.4301 | – | – | – | – |

| Stainless Steel 304 | Z7CN18‐09 | S30400 | 1.4301 | SUS 304 | 08Х18Н10 | 304S31 | X5CrNi18-10 |

| SS 310S | – | S31008 | 1.4845 | SUS 310S | 20Ch23N18 | 310S16 | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

| Stainless Steel 316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | S31603 | 1.4404 / 1.4435 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 316S11 / 316S13 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | – | S31609 | 1.4401 | – | – | – | – |

| Stainless Steel 316 | Z7CND17‐11‐02 | S31600 | 1.4401 / 1.4436 | SUS 316 | – | 316S31 / 316S33 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316Ti | Z6CNDT17‐123 | S31635 | 1.4571 | SUS 316Ti | 08Ch17N13M2T | 320S31 | X6CrNiMoTi17-12-2 |

| SS 317 | – | S31700 | 1.4449 | SUS 317 | – | – | – |

| SS 321 | – | S32100 | 1.4541 | SUS 321 | – | – | X6CrNiTi18-10 |

| Stainless Steel 317L | – | S31703 | 1.4438 | SUS 317L | – | – | X2CrNiMo18-15-4 |

| SS 321H | – | S32109 | 1.4878 | SUS 321H | – | – | X12CrNiTi18-9 |

| SS 347H | – | S34709 | 1.4961 | SUS 347H | – | – | X6CrNiNb18-12 |

| SS 347 | – | S34700 | 1.4550 | SUS 347 | 08Ch18N12B | – | X6CrNiNb18-10 |

| Stainless Steel 904L | Z2 NCDU 25-20 | N08904 | 1.4539 | SUS 904L | STS 317J5L | 904S13 | X1NiCrMoCu25-20-5 |

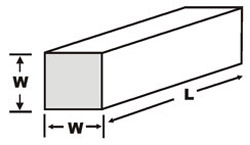

Square Bar Weight Formula

0.00788 X ( mm ) Diam X ( mm ) Diam = Weight / Meter

0.00240 X ( mm ) Diam X ( mm ) Diam = Weight / Feet

|

|