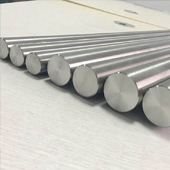

The outstanding qualities of titanium, a rare metal, are its resistance to chlorine ions. However, employing a titanium round bar has the advantage of being lightweight. Being a lightweight metal has benefits for both the user and the installer in terms of weight reduction. The more common stainless steels, like grade 304 or 316, have a tendency to be heavier and denser when employed in applications. Since titanium square bars have a low density, they can be installed more quickly and with greater effectiveness.

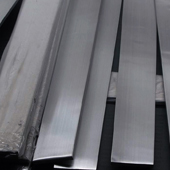

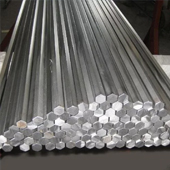

Additionally, titanium's resistance to corrosion is what draws suppliers of titanium round bar. Despite having a density that is 60% higher than aluminium, titanium has a strength that is almost twice as great. Even though Pure Titanium Flat Bar can withstand high temperatures, using heat above 430 °C results in a loss of strength. Commercially pure titanium has softer hardness characteristics than some grades of heat-treated steels because the alloy is ductile. The atmospheric passivation process that the ASTM B348 Ti Alloy Hex Bar goes through gives these bars an exceptional level of corrosion resistance that is virtually comparable to platinum.

before buy compare price of Titanium Round Bar with Monel round bar price list

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Round bar size | Diameter: 3-~800mm |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Bar Round Titanium Alloy. 06.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/1015 Dt 18.11.16 Item No 1) | 5,363 | 72.66 | 59.96 |

| Bar Round Titanium Alloy. Dia 20.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/1015 Dt 18.11.16 Item No 3) | 3,281 | 44.45 | 36.68 |

| Bar Round Titanium Alloy. 16.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/1015 Dt 18.11.16 Item No 4) | 4,050 | 54.87 | 45.28 |

| Bar Round Titanium Alloy. Dia 14.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/885 Dt 07.10.16 Item No 2) | 4,774 | 64.68 | 53.38 |

| Titanium Round Bar 6al-4v 4.53 Diax12 R/l (7 Pcs) | 2,453 | 33.23 | 27.43 |

| Bar Round Titanium Alloy. 18.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/1015 Dt 18.11.16 Item No 2) | 3,669 | 49.71 | 41.02 |

| Bar Round Titanium Alloy. 20.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/885 Dt 07.10.16 Item No1) | 3,281 | 44.45 | 36.68 |

| Bar Round Titanium Alloy. Dia 10.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/885 Dt 07/10/16 Item No 4) | 6,104 | 82.70 | 68.25 |

| Bar Round Titanium Alloy. Dia 12.00mm (C.excise No Vgn(30)26/g.b.adler/rtn/t/2016/885 Dt 07/10/16 Item No 3) | 4,631 | 62.74 | 51.78 |

| Titanium Round Bars | 1,832 | 24.82 | 20.48 |

For titanium segments, bending is a widely accepted cold forming technique. One of the key design considerations for framing such sections is to illustrate the adaptable recovery after dumping, or the so-called spring-back effect. Additionally, residual concerns brought on in the example due to inelastic misshapenings after shaping have a significant impact on the heap transporting limit of the framed component. The experimental device consists of one arm and two rollers. The titanium bar is twisted by the moving roller while being directed by the fixed roller.

For titanium segments, bending is a widely accepted cold forming technique. One of the key design considerations for framing such sections is to illustrate the adaptable recovery after dumping, or the so-called spring-back effect. Additionally, residual concerns brought on in the example due to inelastic misshapenings after shaping have a significant impact on the heap transporting limit of the framed component. The experimental device consists of one arm and two rollers. The titanium bar is twisted by the moving roller while being directed by the fixed roller.

| Diameter | Random Length |

|---|---|

| 0.187 inches4.7498 mm | 10 ft20 ft |

| 1/4 inches6.35 mm | 10 ft20 ft |

| 0.312 inches7.9248 mm | 10 ft20 ft |

| 3/8 inches9.525 mm | 10 ft20 ft |

| 0.437 inches11.0998 mm | 10 ft20 ft |

| 1/2 inches12.70 mm | 10 ft20 ft |

| 0.562 inches14.2748 mm | 10 ft20 ft |

| 5/8 inches15.875 mm | 10 ft20 ft |

| 0.687 inches17.4498 mm | 10 ft20 ft |

| 3/4 inches19.05 mm | 10 ft20 ft |

| 0.812 inches20.6248 mm | 10 ft20 ft |

| 7/8 inches22.225 mm | 10 ft20 ft |

| 0.937 inches23.7998 mm | 10 ft20 ft |

| 1 inches25.40 mm | 10 ft20 ft |

| 1.062 inches26.9748 mm | 10 ft20 ft |

| 1 1/8 inches28.575 mm | 10 ft20 ft |

| 1.187 inches30.1498 mm | 10 ft20 ft |

| 1 1/4 inches31.75 mm | 10 ft20 ft |

| 1.312 inches33.3248 mm | 10 ft20 ft |

| 1.375 inches34.925 mm | 10 ft20 ft |

| 1.437 inches36.4998 mm | 10 ft20 ft |

| 1 1/2 inches38.10 mm | 10 ft20 ft |

| 1.562 inches39.6748 mm | 10 ft20 ft |

| 1 5/8 inches41.275 mm | 10 ft20 ft |

| 1.687 inches42.8498 mm | 10 ft20 ft |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

Types of Packaging:

– Bundles (hexagonal)

– Wooden Boxes

– Crates (steel/wooden)

– Packaging for Rod as per customer’s requirements

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

|---|---|---|---|---|---|---|---|

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Round Bar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3" | 10.900 | 35.762 |

| 1/8" | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4" | 12.800 | 41.996 |

| 5/32" | 0.029 | 0.095 | 7/8" | 0.926 | 3.038 | 3-1/2" | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4" | 17.001 | 55.780 |

| 3/16" | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4" | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1" | 1.210 | 3.970 | 4-1/4" | 21.908 | 72.249 |

| 7/32" | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2" | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4" | 27.366 | 90.249 |

| 1/4" | 0.076 | 0.249 | 1-1/8" | 1.534 | 5.033 | 5" | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2" | 36.690 | 121.000 |

| 5/16" | 0.118 | 0.387 | 1-1/4" | 1.924 | 6.349 | 6" | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2" | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8" | 2.303 | 7.550 | 7" | 59.432 | 196.000 |

| 3/8" | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2" | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8" | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10" | 121.048 | 397.140 |

| 7/16" | 0.232 | 0.761 | 1-1/2" | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2" | 0.303 | 0.994 | 1-5/8" | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4" | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16" | 0.383 | 1.256 | 1-7/8" | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8" | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2" | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8" | 5.475 | 17.963 | |||

| 11/16" | 0.573 | 1.880 | 2-1/4" | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4" | 0.682 | 2.237 | 2-3/8" | 6.838 | 22.435 | |||

| 2-1/2" | 7.576 | 24.856 | ||||||

| 2-5/8" | 8.354 | 27.409 | ||||||

| 2-3/4" | 9.169 | 30.083 | ||||||

Titanium Flat bar – metric sizes and weights |

|||

|---|---|---|---|

Flat Size |

KG’s per Metre |

Standard Length (metres) |

Colour Code |

10 x 3 |

0.24 |

6.0 |

Blue |

13 x 3 |

0.31 |

6.0 |

Blue |

13 x 5 |

0.46 |

6.0 |

Orange |

16 x 3 |

0.38 |

6.0 |

Blue |

16 x 5 |

0.64 |

6.0 |

Orange |

16 x 8 |

1.03 |

6.0 |

Red |

20 x 3 |

0.48 |

6.0 |

Blue |

20 x 5 |

0.81 |

6.0 |

Orange |

20 x 6 |

0.97 |

6.0 |

White |

20 x 10 |

1.61 |

6.0 |

Yellow |

25 x 3 |

0.60 |

6.0 |

Blue |

25 x 5 |

1.01 |

6.0 |

Orange |

25 x 6 |

1.21 |

6.0 |

White |

25 x 8 |

1.61 |

6.0 |

Red |

25 x 10 |

2.01 |

6.0 |

Yellow |

25 x 12 |

2.41 |

6.0 |

Pink |

32 x 3 |

0.77 |

6.0 |

Blue |

32 x 5 |

1.29 |

6.0 |

Orange |

32 x 6 |

1.55 |

6.0 |

White |

32 x 8 |

2.06 |

6.0 |

Red |

32 x 10 |

2.58 |

6.0 |

Yellow |

32 x 12 |

3.09 |

6.0 |

Pink |

40 x 3 |

0.97 |

6.0 |

Blue |

40 x 5 |

1.61 |

6.0 |

Orange |

40 x 6 |

1.93 |

6.0 |

White |

40 x 8 |

2.58 |

6.0 |

Red |

40 x 10 |

3.22 |

6.0 |

Yellow |

40 x 12 |

3.86 |

6.0 |

Pink |

40 x 16 |

5.15 |

6.0 |

Grey |

40 x 20 |

6.14 |

6.0 |

Green |

50 x 3 |

1.21 |

6.0 |

Blue |

50 x 5 |

2.01 |

6.0 |

Orange |

50 x 6 |

2.41 |

6.0 |

White |

50 x 8 |

3.22 |

6.0 |

Red |

50 x 10 |

4.02 |

6.0 |

Yellow |

50 x 12 |

4.83 |

6.0 |

Pink |

50 x 16 |

6.44 |

6.0 |

Grey |

50 x 20 |

8.05 |

6.0 |

Green |

50 x 25 |

10.1 |

6.0 |

Purple |

65 x 3 |

1.57 |

6.0 |

Blue |

65 x 5 |

2.62 |

6.0 |

Orange |

65 x 6 |

3.14 |

6.0 |

White |

65 x 8 |

4.18 |

6.0 |

Red |

65 x 10 |

5.23 |

6.0 |

Yellow |

65 x 12 |

6.28 |

6.0 |

Pink |

65 x 16 |

8.37 |

6.0 |

Grey |

65 x 20 |

10.5 |

6.0 |

Green |

65 x 25 |

13.1 |

6.0 |

Purple |

75 x 5 |

3.02 |

6.0 |

Orange |

75 x 6 |

3.62 |

6.0 |

White |

75 x 8 |

4.83 |

6.0 |

Red |

75 x 10 |

6.04 |

6.0 |

Yellow |

75 x 12 |

7.24 |

6.0 |

Pink |

75 x 16 |

9.66 |

6.0 |

Grey |

75 x 20 |

12.1 |

6.0 |

Green |

75 x 25 |

15.1 |

6.0 |

Purple |

75 x 40 |

24.1 |

6.0 |

Yellow |

90 x 5 |

3.62 |

6.0 |

Orange |

90 x 6 |

4.35 |

6.0 |

White |

90 x 8 |

5.79 |

6.0 |

Red |

90 x 10 |

7.24 |

6.0 |

Yellow |

90 x 12 |

8.69 |

6.0 |

Pink |

100 x 5 |

4.02 |

6.0 |

Orange |

100 x 6 |

4.83 |

6.0 |

White |

100 x 8 |

6.44 |

6.0 |

Red |

100 x 10 |

8.05 |

6.0 |

Yellow |

100 x 12 |

9.66 |

6.0 |

Pink |

100 x 16 |

12.9 |

6.0 |

Grey |

100 x 20 |

16.1 |

6.0 |

Green |

100 x 25 |

20.1 |

6.0 |

Purple |

100 x 50 |

40.2 |

6.0 |

Green |

110 x 6 |

5.31 |

6.0 |

White |

110 x 8 |

7.08 |

6.0 |

Red |

110 x 10 |

8.85 |

6.0 |

Yellow |

110 x 12 |

10.6 |

6.0 |

Pink |

130 x 5 |

5.23 |

6.0 |

Orange |

130 x 6 |

6.28 |

6.0 |

White |

130 x 8 |

8.37 |

6.0 |

Red |

130 x 10 |

10.5 |

6.0 |

Yellow |

130 x 12 |

12.6 |

6.0 |

Pink |

130 x 16 |

16.7 |

6.0 |

Grey |

130 x 20 |

20.9 |

6.0 |

Green |

130 x 25 |

26.2 |

6.0 |

Purple |

150 x 5 |

6.04 |

6.0 |

Orange |

150 x 6 |

7.24 |

6.0 |

White |

150 x 8 |

9.66 |

6.0 |

Red |

150 x 10 |

12.1 |

6.0 |

Yellow |

150 x 12 |

14.5 |

6.0 |

Pink |

150 x 16 |

19.3 |

6.0 |

Grey |

150 x 20 |

24.1 |

6.0 |

Green |

150 x 25 |

30.1 |

6.0 |

Purple |

150 x 50 |

60.4 |

6.0 |

Green |

180 x 5 |

7.24 |

6.0 |

Orange |

180 x 6 |

8.69 |

6.0 |

White |

180 x 10 |

14.5 |

6.0 |

Yellow |

180 x 12 |

17.4 |

6.0 |

Pink |

180 x 16 |

23.2 |

6.0 |

Grey |

180 x 20 |

29.0 |

6.0 |

Green |

180 x 25 |

36.2 |

6.0 |

Purple |

200 x 6 |

9.66 |

6.0 |

White |

200 x 8 |

12.9 |

6.0 |

Red |

200 x 10 |

16.1 |

6.0 |

Yellow |

200 x 12 |

19.3 |

6.0 |

Pink |

200 x 16 |

25.7 |

6.0 |

Grey |

200 x 20 |

32.2 |

6.0 |

Green |

200 x 25 |

40.3 |

6.0 |

Purple |

250 x 6 |

12.1 |

6.0 |

White |

250 x 8 |

16.1 |

6.0 |

Red |

250 x 10 |

20.1 |

6.0 |

Yellow |

250 x 12 |

24.1 |

6.0 |

Pink |

250 x 16 |

32.2 |

6.0 |

Grey |

250 x 20 |

40.2 |

6.0 |

Green |

250 x 25 |

50.3 |

6.0 |

Purple |

300 x 6 |

14.5 |

6.0 |

White |

300 x 8 |

19.3 |

6.0 |

Red |

300 x 10 |

24.1 |

6.0 |

Yellow |

300 x 12 |

29.0 |

6.0 |

Pink |

300 x 16 |

38.6 |

6.0 |

Grey |

300 x 20 |

48.3 |

6.0 |

Green |

300 x 25 |

60.4 |

6.0 |

Purple |

|

|

| H&T | Hardened and tempered. |

| ANN | Annealed |

| PH | Precipitation hardened. |

hex bar Size in Inches |

hex bar Wt per Ft |

hex bar Wt per 12′ |

|---|---|---|

3/16″ |

0.104 |

1.248 |

1/4″ |

0.180 |

2.160 |

5/16″ |

0.290 |

3.480 |

3/8″ |

0.600 |

4.920 |

7/16″ |

0.560 |

6.72 |

1/2″ |

0.740 |

8.880 |

9/16″ |

0.930 |

11.16 |

5/8″ |

1.150 |

13.80 |

11/16″ |

1.390 |

16.68 |

3/4″ |

1.660 |

19.92 |

13/16″ |

1.950 |

23.40 |

7/8″ |

2.300 |

27.60 |

15/16″ |

2.600 |

31.20 |

1″ |

2.90 |

34.80 |

1-1/16″ |

3.30 |

39.60 |

1-1/8″ |

3.700 |

44.40 |

1-1/4″ |

4.600 |

55.20 |

1-5/16″ |

5.100 |

61.20 |

1-3/8″ |

5.600 |

67.20 |

1-7/16″ |

6.100 |

73.20 |

1-1/2″ |

6.600 |

79.20 |

1-5/8″ |

7.800 |

93.60 |

1-3/4″ |

9.030 |

108.36 |

1-7/8″ |

10.400 |

124.80 |

2″ |

11.80 |

141.60 |

2-1/4″ |

14.920 |

179.04 |

2-3/8″ |

16.920 |

203.04 |

2-1/2″ |

18.42 |

221.04 |

3″ |

26.53 |

318.36 |

0.2% Proof Stress |

Tensile Strength |

Elongation |

Reduction of area |

Hardness |

|---|---|---|---|---|

MPA |

MPA |

% |

% |

HRC |

Min |

Min |

Min |

Min |

Min |

827 |

1034 |

17 |

25 |

40 |

Specifications: |

ASME SB-348, ASTM F-67, AMS 4921 |

International Specifications: |

W. NR. 3.7035, W. NR. 3.7034 |

| Grades | UNS | Grades | UNS |

|---|---|---|---|

| CP Grade 1 | R50350 | CP Grade 2 | R50400 |

| CP Grade 3 | R50550 | CP Grade 4 | R50700 |

| Titanium Grade 6 | R54520 | CP Grade 7 | R52400 |

| Titanium Grade 9 | R56320 | CP Grade 11 | R52252 |

| CP Grade 12 | R53400 | CP Grade 16 | R52402 |

| CP Grade 17 | R52252 | CP Grade 26 | R52404 |

| CP Grade 27 | R52404 | Titanium Grade 28 | R56323 |

| Titanium Grade 29 | R56404 | Ti-10V-2Fe-3Al | R56410 |

| Ti-13V-11Cr-3Al3-8-6-44 | R58010 | Ti-2.5Cu | – |

| Ti-3Al-8V-6Cr-4Mo-4Zr | – | Ti-4Al-4Mo-2Sn | – |

| Ti-5-2.5Sn ELI | R54521 | Ti-5.8Al-4.0Sn-3.5Zr-0.7Nb-0.5Mo-0.35Si-0.06C | – |

| Ti-5Al-1Sn-1Zr-1V-0.8Mo | – | Ti-5Al-2Zr-2Sn-4Mo-4Cr | R58650 |

| Ti-6Al-2Sn-2Zr-2Mo-2Cr-0.15Si | R56222 | Ti-6Al-2Sn-4Zr-2Mo | R54620 |

| Ti-6Al-2Sn-4Zr-6Mo | R56260 | Ti-6Al-4V | R56400 |

| Ti-6Al-4V ELI | R56407 | Ti-6Al-6V-2Sn | R56620 |

| Ti-6Al-7Nb | R56700 | Ti-7Al-4Mo | R56740 |

| Ti-8Al-1Mo-1V | R54810 | TIMETAL 21S | – |

| Grade | C | N | O | H | Ti | Fe |

|---|---|---|---|---|---|---|

| Gr 1 | .08 Max | .03 Max | .18 Max | .015 Max | Bal | .20 Max |

| Gr 4 | .08 Max | .05 Max | .40 Max | .015 Max | Bal | .50 Max |

| Gr 7 | .08 Max | .03 Max | .25 Max | .015 Max | Bal | .30 Max |

| Gr 9 | .08 Max | .03 Max | .15 Max | .015 Max | - | .25 Max |

| Gr 12 | .08 Max | .03 Max | .25 Max | 0.15 Max | - | .30 Max |

| Grade | Tensisle Strength | Yield Strength | Elogation In 2 In. Or 50mm Min.,% |

Bend Test | |||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Min | Min | Min | Max | Max | Under 0.070 In. (1.8mm) Thickness |

0.070 To 0.187 In. (1.8mm To 4.75mm) Thickness |

||

| Ksi | Mpa | Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 | 1.5T | 2T |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 | 2T | 2.5T |

| 3 | 65 | 450 | 55 | 380 | 80 | 550 | 18 | 2T | 2.5T |

| 4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 | 2.5T | 3T |

| 5 | 130 | 895 | 120 | 828 | ... | ... | 10 | 4.5T | 5T |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 | 2T | 2.5T |

| 9 | 90 | 620 | 70 | 483 | ... | ... | 15 | 2.5T | 3T |

| 12 | 70 | 483 | 50 | 345 | ... | ... | 18 | 2T | 2.5T |

| ASTM B348 Ti Rectangular Bar Polished | Titanium ASTM B348 Polished Round Bar |

| Titanium ASTM B348 Square Bar | ASTM B348 Ti Alloy Polished Flat Bar |

| ASTM B348 Ti Threaded Bar M16 | Titanium Threaded Rods |

| ASTM B348 Ti Alloy Rectangular Bar stock | ASTM B348 Titanium Polished Bar Stock |

| Titanium ASTM B348 Rectangular Bar Cold Drawn | ASTM B348 Titanium Polished Square Bar |

| ASTM B348 Ti Alloy Square Bar Black | Titanium ASTM B348 Black Bar |

| ASTM B348 Square Bar Annealed | Titanium Bright Bar Flat |

| Ti Rectangular Bar Black | ASTM B348 Bright Bar Hex |

| 6al-4v titanium round bar | grade 4 titanium round bar |

| 10mm titanium round bar | pure titanium round bar |

| titanium grade 12 round bar | grade 9 titanium round bar |

| 7mm titanium round bar | 8mm titanium round bar |

| Titanium Square Bar Bright | ASTM B348 Titanium Bright Bar Cold Drawn |

| Tolerances for Cold Drawn Titanium Round Bar | ||

|---|---|---|

| Shape / Section | Size, diameter or width across flats | Permitted variation |

| mm | mm | |

| Round | ≥6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 |

+ 0 to - 0.070 + 0 to - 0.085 + 0 to - 0.100 + 0 to - 0.120 + 0 to - 0.140 |

| Flat (thickness) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 |

+ 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.250 + 0 to - 0.350 |

| Flat (width) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 > 100 ≦ 130 > 130 ≦ 160 > 160 ≦ 320 |

+ 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.160 + 0 to - 0.190 + 0 to - 0.220 + 0 to - 0.350 + 0 to - 1.00 + 1.00 to - 1.00 |

| Square and hexagon |

≥ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 105 |

+ 0 to - 0.090 + 0 to - 0.110 + 0 to - 0.130 + 0 to - 0.160 + 0 to - 0.250 |

Tolerances of Turned ASTM B348 Titanium Round Bar (BS 970-3)

| Turned Titanium round bar Tolerances | |

|---|---|

| Titanium round bar Size, diameter | Permitted variation |

| mm | mm |

| ≧ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 120 > 120 ≦ 180 > 180 ≦ 250 > 250 ≦ 315 > 315 ≦ 400 > 400 |

+ 0 to - 0.070 + 0 to - 0.085 + 0 to - 0.100 + 0 to - 0.120 + 0 to - 0.140 + 0 to - 0.160 + 0 to - 0.185 + 0 to - 0.210 + 0 to - 0.230 + 0 to - 0.250 |

Tolerances of Precision Titanium ASTM B348 Round Bar (BS 970-3)

| PrecisionTitanium ASTM B348 Round Bar Tolerances | ||||

|---|---|---|---|---|

| Section | Size, diameter |

Permitted overall variation | ||

| Class A | Class B | Class C | ||

| mm | mm | mm | mm | |

| Round | ≧ 6 <75 | 0.05 | 0.025 | 0.013 |

Tolerance of Titanium Alloy Bright Round Bar (BS EN ISO 286-2 )

| Titanium round bar Tolerance ISO “H” Series in MM | ||||||||

|---|---|---|---|---|---|---|---|---|

| NOMINAL SIZE | h5 | h6 | h7 | h8 | h9 | H10 | H11 | h12 |

| DIAMETER mm | ||||||||

| ~ to 3 | +0.004/0 | +0.006/0 | +0.01/0 | +0.014/0 | +0.025/0 | +0.04/0 | +0.06/0 | +0.1/0 |

| over 3 to 6 | +0.005/0 | +0.008/0 | +0.012/0 | +0.018/0 | +0.03/0 | +0.048/0 | +0.075/0 | +0.12/0 |

| over 6 to 10 | +0.006/0 | +0.009/0 | +0.015/0 | +0.022/0 | +0.036/0 | +0.058/0 | +0.09/0 | +0.15/0 |

| over 10 to 18 | +0.008/0 | +0.011/0 | +0.018/0 | +0.027/0 | +0.043/0 | +0.07/0 | +0.11/0 | +0.18/0 |

| over 18 to 30 | +0.009/0 | +0.013/0 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 | +0.13/0 | +0.21/0 |

| over 30 to 50 | +0.011/0 | +0.016/0 | +0.025/0 | +0.039/0 | +0.062/0 | +0.1/0 | +0.16/0 | +0.25/0 |

| over 50 to 80 | +0.013/0 | +0.019/0 | +0.03/0 | +0.046/0 | +0.074/0 | +0.12/0 | +0.19/0 | +0.3/0 |

| over 80 to 120 | +0.015/0 | +0.022/0 | +0.035/0 | +0.054/0 | +0.087/0 | +0.14/0 | +0.22/0 | +0.35/0 |

| over 120 to 180 | +0.018/0 | +0.025/0 | +0.04/0 | +0.063/0 | +0.1/0 | +0.16/0 | +0.25/0 | +0.4/0 |

| over 180 to 250 | +0.02/0 | +0.029/0 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 | +0.29/0 | +0.46/0 |