compare Stainless Steel Welded Pipe price with Stainless Steel Seamless Pipe price list

Several stainless steel alloys can be weld readily using different traditional methods. However, every manufacturer of stainless steel welded pipes in India agrees that an alloy with little carbon content is the most advantageous. Low carbon alloys stop carbide precipitates from forming on the grain. And as a result, any low carbon version of large diameter stainless steel welded pipe, including alloys like 304, 316, 310, etc., tends to have more improved weldability features in addition to not becoming susceptible to intergranular corrosion.

Because the weld seam may become sensitive and create carbide precipitates at high temperatures, corrosion is typically an issue with high carbon stainless steel erw pipes. When transporting different fluids or gases under high pressure, stainless steel welded pipes typically employed at high temperatures emit steam. It is crucial that the purchaser choose the proper Stainless Steel Welded Pipe Pressure Rating, one that corresponds to the pressure required for the application. In addition to the pressure rating, the size of the piping is crucial. Using the proper stainless steel welded pipe size is crucial because the environment affects the application as well.

Conditions such as heat and cold can cause the metal to either expand or contract. The Stainless Steel Welded Pipe Astm A312 may also degrade quickly depending on the climate. For instance, high temperatures and humidity combined with the application could hasten the oxidation of the stainless steel efw pipe. In other cases, the pipes are also impacted by the pollutants in the air. Duty On Stainless Steel Welded Pipe corrosion can be reduced by not only choosing the right alloy but also by applying exterior treatments like polishing, galvanising, or electroplating to get rid of any extra contamination. These procedures either totally cover the Astm A312 Welded Pipe or remove any remaining coating to create a smoother surface and a protective layer as well.

| Los Alamos -Mexico, Egypt, Mexico, Malaysia | Custom Size 8 Inch Stainless Steel Welded Pipe |

| Malaysia, Netherlands, Russia, Sweden, Brazil | Decorative 6 inch welded polished stainless steel pipe |

| NY 12203 (USA), United Kingdom -UK, Malaysia, Singapore | 20mm diameter stainless steel welded pipe mirror polished |

| Romania, United Arab Emirates (UAE), Norway, Europe | Customized 2b surface welded stainless steel pipe |

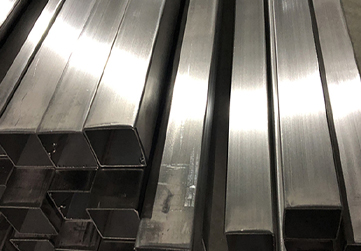

| Philippines, UK, Poland, Dammam -KSA | Square / Rectangle Stainless Steel welded Pipe |

| Thailand, Malaysia, Japan, Czechia | micro/capillary thin wall stainless steel welded pipe |

| Canada, Nigeria, Australia, Ellington -United States | Thickness 9.0mm welded stainless steel pipe |

| Europe, Singapore, Malaysia, Qatar | 4 Inch Stainless Steel Welded Pipe |

| Canada, Chile, Iran, Philippines | Small Diameter 10MM Round Threaded Stainless Steel Welded Pipe |

| Kuwait, Philippines, Taiwan, South Africa | ASTM A312/A213 Cold/Hot Rolling Pickling Welded Stainless Steel Pipe |

| Hong Kong, Thailand, France, Oman | ASTM Standard 200/300/400 Series Welded Stainless Steel Pipe |

| Bangladesh, China, Colombia, Malaysia | 80*1.5*6000mm Polished Stainless Steel Welded pipe |

| UK, Belgium, Indonesia, Philippines | 19mm stainless steel welded pipe |

| Singapore, Malaysia, South Korea, Bahrain | Thickness 5 Inch Stainless Steel ERW Pipe |

| Turkey, Malaysia, Germany | welded medical stainless steel precision pipe 0.32mm*0.1mm |

| Italy, UAE, Malaysia, Singapore | 6 inch stainless steel welded pipe |

| Spain, Brazil, Saudi Arabia (KSA), UK | decorative 3 inch welded stainless steel pipe |

| Malaysia, Finland, USA, Dubai | 200x200 35x35 Welded Stainless Steel Rectangular/Square Pipe |

| Europe, Singapore, South Africa, UAE | micro/capillary thin wall stainless steel welded pipe |

| Standard Specifications | ASTM A268, A213, A270, A778, A312, A249,A269, |

| Welded Pipes Sch | SCH60, SCH120, SCH80, STD, SCH30, SCH20, XS, XXS, SCH80, SCH140, SCH40, SCH160 |

| Dimensions | ASME, ASTM, and API |

| Grade | 321H, Duplex, 321, UNS31803 310S, 316Ti, 304L, 316L, 304H, 316, 347, 304, 347H |

| Available Type | Fabricated, ERW , Welded , LSAW Pipes |

| End | Plain End, Beveled End, Treaded |

| Welded Pipes Form | Round, Square, Rectangular, HydraulicEtc |

| Condition | Hot Finish, Cold Finish, Bright Annealed, Polished, Welded Annealed & Pickled, Externally Polished, Welded Cold Drawn Annealed & Pickled, Stress Relived, Passivated |

| Size | 1/4” Outside Diameter to 36” Outside Diameter and 1/8” Nominal Bore to 36” Nominal Bore or as per requirment |

| Reports | PMI Test Reports or Other Test Reports, 100% X-Ray Welding Reports, NABL Approved Lab Report, NDT, EN 10204 3.1 Certificate |

| Finish | No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Welded Pipes |

| Welded Pipes Thickness | as per ANSI B36.19/36.10 1 milimeter to 20 milimeter , 120/120S ,5/5S, SCH 10/10S, 160/160S, 20/20S, 40/40S, 80/80S |

| Length | Single and Double Random & Cut Length. |

| Welded Pipes Grade | Mn | C | Fe | P | Si | S | Mo | Ti | Cr | N | Ni | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 | minimum | 18.00 | 8.00 | |||||||||

| maximum | 2.00 | 0.008 | 0.0045 | 0.075 | 0.0030 | 20.00 | 0.010 | 10.05 | ||||

| 304L | minimum | 18.00 | 8.00 | |||||||||

| maximum | 2.00 | 0.0030 | 0.0045 | 0.075 | 0.0030 | 20.00 | 0.010 | 12.00 | ||||

| 304H | minimum | 0.004 | 18.00 | 8.00 | ||||||||

| maximum | 2.00 | 0.0010 | 0.0045 | 0.075 | 0.0030 | 20.00 | 10.05 | |||||

| SS 310 | 2 maximum | 0.0015 maximum | 0.0020 maximum | 0.0015 maximum | 0.0015 maximum | 0.010 maximum | 24.000 26.000 | 54.07 minimum | 19.000 21.000 | |||

| SS 310S | 2 maximum | 0.008 maximum | 0.0045 maximum | 1.000 maximum | 0.0030 maximum | 0.075 maximum | 24.000 26.000 | 53.0095 minimum | 19.000 21.000 | |||

| SS 310H | 2 maximum | 0.004 0.010 | 0.0045 maximum | 1.000 maximum | 0.0030 maximum | 24.000 26.000 | 53.0885 minimum | 19.000 21.000 | ||||

| 316 | minimum | 2.003.00 | 16.00 | 10.00 | ||||||||

| maximum | 2.00 | 0.0035 | 0.0045 | 0.075 | 0.0030 | 18.00 | 14.00 | |||||

| 316L | minimum | 2.003.00 | 16.00 | 10.00 | ||||||||

| maximum | 2.00 | 0.0035 | 0.0045 | 0.075 | 0.0030 | 18.00 | 14.00 | |||||

| 316TI | 10.000 14.000 | 0.008 maximum | 0.0045 maximum | 2.00 maximum | 0.0030 maximum | 0.075 maximum | 16.000 18.000 | 2.000 3.000 | ||||

| 317 | 2 maximum | 0.008 maximum | 57.0845 minimum | 0.0045 maximum | 1 maximum | 0.0030 maximum | 3.000 4.000 | 18.000 20.000 | ||||

| SS 317L | 2.00 maximum | 0.0035 maximum | 57.089 minimum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 3.000 4.000 | 18.000 20.000 | 11.000 15.000 | |||

| SS 321 | 2.00 maximum | 0.008 maximum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 5(C+N) 0.070 maximum | 17.000 19.000 | 0.010 maximum | 9.000 12.000 | |||

| SS 321H | 2.00 maximum | 0.004 0.010 | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 4(C+N) 0.070 maximum | 17.000 19.000 | 0.010 maximum | 9.000 12.000 | |||

| 347/ 347H | 2.00 maximum | 0.008 maximum | 0.0045 maximum | 1.00 maximum | 0.0030 maximum | 17.000 20.000 | 9.00013.000 | |||||

| 410 | minimum | 11.05 | ||||||||||

| maximum | 1.00 | 0.015 | 0.0040 | 1.000 | 0.0030 | 13.05 | 0.075 | |||||

| 446 | minimum | 23.00 | 0.010 | |||||||||

| maximum | 1.05 | 0.02 | 0.0040 | 0.075 | 0.0030 | 30.00 | 0.025 | 0.050 | ||||

| 904L | minimum | 4.000 | 19.00 | 0.010 | 23.000 | |||||||

| maximum | 2.000 | 0.020 | 0.0045 | 1.000 | 0.0035 | 5.000 | 23.00 | 0.025 | 28.000 | |||

| Welded Pipes Grade | Density | Tensile Strength | Elongation | Melting Point | Yield Strength |

|---|---|---|---|---|---|

| 304H | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 40 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| 304/ 304L | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| 904L | 7.95 g/centimeter3 | MPa 490, Psi 71000 | 35 % | (2460 °F) 1350 °C | MPa 220, Psi 32000 |

| 306/ 316H | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1400 °C | MPa 205, Psi 30000 |

| 310 / 310S / 310H | 7.9 g/centimeter3 | MPa 515, Psi 75000 | 40 % | (2555 °F) 1402 °C | MPa 205, Psi 30000 |

| 316L | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F) 1399 °C | MPa 205, Psi 30000 |

| 321 | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2650 °F) 1457 °C | MPa 205, Psi 30000 |

| 317 | 7.9 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2550 °F)1400 °C | MPa 205, Psi 30000 |

| 347 | 8.0 g/centimeter3 | MPa 515, Psi 75000 | 35 % | (2650 °F) 1454 °C | MPa 205, Psi 30000 |

| Welded Pipes STANDARD | AFNOR | UNS | WERKSTOFF NR. | JIS | GOST | BS | EN |

|---|---|---|---|---|---|---|---|

| SS 304L | Z3CN18‐10 | S30403 | 1.4306 / 1.4307 | SUS 304L | 03Х18Н11 | 3304S11 | X2CrNi18-9 / X2CrNi19-11 |

| SS 310 | – | S31000 | 1.4841 | SUS 310 | 20Ch25N20S2 | 310S24 | X15CrNi25-20 |

| SS 304H | – | S30409 | 1.4301 | – | – | – | – |

| SS 304 | Z7CN18‐09 | S30400 | 1.4301 | SUS 304 | 08Х18Н10 | 304S31 | X5CrNi18-10 |

| SS 310S | – | S31008 | 1.4845 | SUS 310S | 20Ch23N18 | 310S16 | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

| SS 316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | S31603 | 1.4404 / 1.4435 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 316S11 / 316S13 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | – | S31609 | 1.4401 | – | – | – | – |

| SS 316 | Z7CND17‐11‐02 | S31600 | 1.4401 / 1.4436 | SUS 316 | – | 316S31 / 316S33 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316Ti | Z6CNDT17‐123 | S31635 | 1.4571 | SUS 316Ti | 08Ch17N13M2T | 320S31 | X6CrNiMoTi17-12-2 |

| SS 317 | – | S31700 | 1.4449 | SUS 317 | – | – | – |

| SS 321 | – | S32100 | 1.4541 | SUS 321 | – | – | X6CrNiTi18-10 |

| SS 317L | – | S31703 | 1.4438 | SUS 317L | – | – | X2CrNiMo18-15-4 |

| SS 321H | – | S32109 | 1.4878 | SUS 321H | – | – | X12CrNiTi18-9 |

| SS 347H | – | S34709 | 1.4961 | SUS 347H | – | – | X6CrNiNb18-12 |

| SS 347 | – | S34700 | 1.4550 | SUS 347 | 08Ch18N12B | – | X6CrNiNb18-10 |

| SS 904L | Z2 NCDU 25-20 | N08904 | 1.4539 | SUS 904L | STS 317J5L | 904S13 | X1NiCrMoCu25-20-5 |

| OD Inches | Pipe Size | TRUE 5 | 5s | TRUE 40 | 40s and STD | 30 | 20 | 60 | TRUE 10 | 10s |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0405 | 1/8 | 0.035 | 0.00068 | 0.00068 | 0.00049 | 0.00049 | ||||

| 0.01383 | 0.02447 | 0.02447 | 0.01863 | 0.01863 | ||||||

| 0.054 | 1/4 | 0.00049 | 0.00088 | 0.00088 | 0.00065 | 0.00065 | ||||

| 0.0257 | 0.04248 | 0.04248 | 0.03297 | 0.03297 | ||||||

| 0.0675 | 3/8 | 0.00049 | 0.00091 | 0.00091 | 0.00065 | 0.00065 | ||||

| 0.03276 | 0.05676 | 0.05676 | 0.04235 | 0.04235 | ||||||

| 0.084 | 1/2 | 0.00065 | 0.00065 | 0.0109 | 0.0109 | 0.00083 | 0.00083 | |||

| 0.05383 | 0.05383 | 0.0851 | 0.0851 | 0.0671 | 0.0671 | |||||

| 1.005 | 3/4 | 0.00065 | 0.00065 | 0.0113 | 0.0113 | 0.00083 | 0.00083 | |||

| 0.06838 | 0.06838 | 1.0131 | 1.0131 | 0.08572 | 0.08572 | |||||

| 1.0315 | 1 | 0.00065 | 0.00065 | 0.0133 | 0.0133 | 0.019 | 0.0109 | |||

| 0.08678 | 0.08678 | 1.0679 | 1.0679 | 1.0404 | 1.0404 | |||||

| 1.066 | 1 1/4 | 0.00065 | 0.00065 | 0.014 | 0.014 | 0.0109 | 0.0109 | |||

| 1.0107 | 1.0107 | 2.0273 | 2.0273 | 1.0806 | 1.0806 | |||||

| 1.09 | 1 1/2 | 0.00065 | 0.00065 | 0.0145 | 0.0145 | 0.0109 | 0.0109 | |||

| 1.0274 | 1.0274 | 2.0718 | 2.0718 | 2.0638 | 2.0638 | |||||

| 2.0375 | 2 | 0.00065 | 0.00065 | 0.0154 | 0.0154 | 0.0109 | 0.0109 | |||

| 1.0604 | 1.0604 | 3.0653 | 3.0653 | 2.0638 | 2.0638 | |||||

| 2.0875 | 2 1/2 | 0.00083 | 0.00083 | 0.0203 | 0.0203 | 0.012 | 0.012 | |||

| 2.0475 | 2.0475 | 5.0793 | 5.0793 | 3.0531 | 3.0531 | |||||

| 3.05 | 3 | 0.00083 | 0.00083 | 0.0216 | 0.0216 | 0.012 | 0.012 | |||

| 3.0029 | 3.0029 | 7.0576 | 7.0576 | 4.0332 | 4.0332 | |||||

| 4 | 3 1/2 | 0.00083 | 0.00083 | 0.0226 | 0.0226 | 0.012 | 0.012 | |||

| 3.0472 | 3.0472 | 9.0109 | 9.0109 | 4.097 | 4.097 | |||||

| 4.05 | 4 | 0.00083 | 0.00083 | 0.0237 | 0.0237 | 0.0281 | 0.012 | 0.012 | ||

| 3.0915 | 3.0915 | 10.079 | 10.079 | 12.066 | 5.0613 | 5.0613 | ||||

| 5 | 4 1/2 | 0.0247 | ||||||||

| 12.053 | ||||||||||

| 5.0563 | 5 | 0.0109 | 0.0109 | 0.0258 | 0.0258 | 0.0134 | 0.0134 | |||

| 6.0349 | 6.0349 | 14.062 | 14.062 | 7.077 | 7.077 | |||||

| 6.0625 | 6 | 0.0109 | 0.0109 | 0.028 | 0.028 | 0.0134 | 0.0134 | |||

| 7.0585 | 7.0585 | 18.097 | 18.097 | 9.0289 | 9.0289 | |||||

| 7.0625 | 7 | 0.0301 | ||||||||

| 23.057 | ||||||||||

| 8.0625 | 8 | 0.0109 | 0.0109 | 0.0322 | 0.0322 | 0.0277 | 0.025 | 0.0406 | 0.0148 | 0.0148 |

| 9.0914 | 9.0914 | 28.055 | 28.055 | 24.07 | 22.036 | 35.064 | 13.04 | 13.04 | ||

| 9.0625 | 9 | 0.0342 | ||||||||

| 33.09 | ||||||||||

| 10.075 | 10 | 0.0134 | 0.0134 | 0.0365 | 0.0365 | 0.0307 | 0.025 | 0.05 | 0.0165 | 0.0165 |

| 15.019 | 15.019 | 40.048 | 40.048 | 34.024 | 28.004 | 54.074 | 18.065 | 18.065 | ||

| 11.075 | 11 | 0.0375 | ||||||||

| 45.055 | ||||||||||

| 12.075 | 12 | 0.0165 | 0.0156 | 0.0406 | 0.0375 | 0.033 | 0.025 | 0.0562 | 0.018 | 0.018 |

| 22.018 | 21.007 | 53.053 | 49.056 | 43.077 | 33.038 | 73.016 | 24.02 | 24.02 | ||

| 16 | 16 | 0.0165 | 0.05 | 0.0375 | 0.0375 | 0.0312 | 0.0656 | 0.025 | 0.0188 | |

| 27.09 | 82.077 | 62.058 | 62.058 | 52.036 | 107.05 | 42.005 | 31.075 | |||

| 14 | 14 | 0.0156 | 0.0437 | 0.0375 | 0.0375 | 0.0312 | 0.0593 | 0.025 | 0.0188 | |

| 23.006 | 63.067 | 54.057 | 54.057 | 45.068 | 84.091 | 36.071 | 27.073 | |||

| 20 | 20 | 0.0188 | 0.0593 | 0.0375 | 0.05 | 0.0375 | 0.0812 | 0.025 | 0.0218 | |

| 39.078 | 122.09 | 78.06 | 104.01 | 78.06 | 166.04 | 52.073 | 46.005 | |||

| 18 | 18 | 0.0165 | 0.0562 | 0.0375 | 0.0437 | 0.0312 | 0.075 | 0.025 | 0.0188 | |

| 31.043 | 104.08 | 70.059 | 82.006 | 59.003 | 138.02 | 47.039 | 35.076 | |||

| 26 | 26 | 0.0375 | 0.05 | 0.0312 | ||||||

| 102.06 | 136.02 | 85.06 | ||||||||

| 24 | 24 | 0.0218 | 0.0687 | 0.0375 | 0.0562 | 0.0375 | 0.0968 | 0.025 | 0.025 | |

| 55.037 | 171.02 | 94.062 | 140.08 | 94.062 | 238.01 | 63.041 | 63.041 | |||

| 30 | 30 | 0.025 | 0.0375 | 0.0625 | 0.05 | 0.0312 | 0.0312 | |||

| 79.043 | 118.06 | 196.01 | 157.05 | 98.093 | 98.093 | |||||

| 42 | 42 | 0.0375 | ||||||||

| 166.07 | ||||||||||

| 28 | 28 | 0.0375 | 0.0625 | 0.05 | 0.0312 | |||||

| 110.06 | 182.07 | 146.08 | 92.026 | |||||||

| 34 | 34 | 0.0688 | 0.0375 | 0.0625 | 0.05 | 0.0312 | ||||

| 244.08 | 134.07 | 222.08 | 178.09 | 112.03 | ||||||

| 32 | 32 | 0.0688 | 0.0375 | 0.0625 | 0.05 | 0.0312 | ||||

| 230.01 | 126.07 | 209.04 | 168.02 | 105.06 | ||||||

| 40 | 40 | 0.0375 | ||||||||

| 158.07 | ||||||||||

| 36 | 36 | 0.075 | 0.0375 | 0.0625 | 0.0312 | |||||

| 282.03 | 142.07 | 236.01 | 118.09 | |||||||

| 48 | 48 | 0.0375 | ||||||||

| 190.07 |

| Outside Diamter of Welded Pipes | Product | Wall Thickness | |

|---|---|---|---|

| 12.7 milimeter* 12.7 milimeter to 300 milimeter* 300 milimeter | Stainless Steel Square Pipe | 0.5 milimeter to 30 milimeter | |

| 6 milimeter to 630 milimeter | Stainless Steel Round Pipe | 0.5 milimeter to 30 milimeter | |

| 10*20 milimeter to 100*200 milimeter | Stainless Steel Rectangular Pipe | 0.5 milimeter to 30 milimeter | |

| 12.7 milimeter to 76.2 milimeter | Stainless Steel Ornamental Pipe | 0.5 milimeter to 2.0 milimeter | |

| 6 milimeter to 630 milimeter | Stainless Steel Colour Coated Pipe | 0.5 milimeter to 30 milimeter | |

| 12.7 milimeter to 250 milimeter | Stainless Steel Electropolished Pipes | 0.5 milimeter to 30 milimeter | |

| 16 milimeter to 85 milimeter | Stainless Steel Pipe | 0.5 milimeter to 3.0 milimeter | |

| 12.7 milimeter to 76.2 milimeter | Stainless Steel Slot Round Pipe | 0.5 milimeter to 2.0 milimeter | |

| 13 milimeter to 85 milimeter | Stainless Steel Hexagonal Pipe | 0.5 milimeter to 2.0 milimeter | |

| 20 milimeter to 200 milimeter | Stainless Steel Pipe | 0.5 milimeter to 2.0 milimeter | |

| 12.7 milimeter to 100 milimeter | SS Polished Pipes | 0.5 milimeter to 2.0 milimeter | |

| 22 milimeter*0.7 milimeter to 108 milimeter*2.0 milimeter | Thin to Wall Stainless Steel Pipe | 0.5 milimeter to 2.0 milimeter | |

| 0.28 milimeter to 10 milimeter | Stainless Steel Pipe | 0.08 milimeter – 1.2 milimeter | |

| 12.5 milimeter to 203.2 milimeter | Inner/Outside Polished Stainless Steel Pipe | 1.0 milimeter – 5 milimeter | |

| 6 milimeter to 430 milimeter | Stainless Steel Seamless Pipe | 0.8 milimeter – 30 milimeter | |

| HS Code | Welded Pipes Description |

|---|---|

| 73053990 | Grade 316 Stainless Steel Secondary / Defective Welded Pipes |

| 73053990 | Grade 304 Stainless Steel Defective Welded Pipe |

| 73053990 | Grade 201 (Nickel Below 1%) Stainless Steel Welded Pipe |

| 73053990 | Grade 316 Stainless Steel Secondary / Defective Welded Pipes |

| 73053990 | Stainless Steel Welded Defective Pipes & Tubes Grade: 304 |

| 73053990 | Stainless Steel Defective Welded Pipes Grade 316 |

| 73053990 | Grade 304 Stainless Steel Welded Defective Pipes |

| 73053990 | 304 Stainless Steel Welded Defective Pipes Grade |

| 73053990 | Stainless Steel Welded Defective Pipes Grade 304 |

| Description | PRice in USD | Per Unit (INR) |

|---|---|---|

| Stainless Steel Defective Welded Pipe Grade 2205 | 1.66 | 123 |

| Stainless Steel Secondary / Defective Welded Pipe Grade 316 | 1.74 | 129 |

| Stainless Steel Defective Welded Pipe Grade 304 | 1.80 | 134 |

| Stainless Steel Secondary / Defective Welded Pipe Grade 304 | 1.39 | 103 |

| Stainless Steel Defective Welded Pipe Grade 304 | 1.59 | 118 |

| Stainless Steel Defective Welded Pipe Grade 316 | 2.01 | 149 |

| TP310S/1.4845Stainless Steel Welded Pipes | TP316L/1.4404Stainless Steel Welded Pipes |

| TP317L/1.4449Stainless Steel Welded Pipes | TP304L/1.4307Stainless Steel Welded Pipes |

| 904LStainless Steel Welded Pipes | TP316Ti/1.4571Stainless Steel Welded Pipes |

| TP321/1.4541Stainless Steel Welded Pipes | TP304/1.4301Stainless Steel Welded Pipes |

| TP309S/1.4833Stainless Steel Welded Pipes | TP316/1.4401Stainless Steel Welded Pipes |

| TP347H/1.4912Stainless Steel Welded Pipes | TP304H/1.4948Stainless Steel Welded Pipes |

|

|

| Welded Pipes Outside Diameter |

Qty/B | 0.007 | 0.006 | 1.000 | 0.009 | 2.000 | 1.005 | 4.000 | 5.000 | 6.000 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches | milimeter | Lgh | Kilogram | Kilogram | Kilogram | Kilogram | Kilogram | Kilogram | Kilogram | Kilogram | Kilogram |

| 1/2" | 12.007 | 100 | 1.0028 | 1.0010 | 1.0078 | 1.0061 | 2.0055 | ||||

| 3/8" | 9.005 | 100 | 0.0094 | 0.0081 | 1.0029 | 1.0018 | 1.0082 | ||||

| 3/4" | 19.001 | 100 | 1.0096 | 1.0069 | 2.0075 | 2.0049 | 4.0001 | ||||

| 5/8" | 15.009 | 100 | 1.0062 | 1.0039 | 2.0026 | 2.0005 | 3.0028 | ||||

| 1" | 25.004 | 100 | 2.0063 | 2.0026 | 3.0071 | 3.0035 | 5.0045 | ||||

| 7/8" | 22.002 | 100 | 2.0029 | 1.0097 | 3.0022 | 2.0091 | 4.0072 | ||||

| 11/4" | 31.008 | 50 | 3.0031 | 2.0084 | 4.0068 | 4.0023 | 6.0091 | ||||

| 11/8" | 28.006 | 50 | 2.0097 | 2.0055 | 4.0019 | 3.0079 | 6.0018 | ||||

| 15/8" | 41.003 | 50 | 4.0032 | 3.0071 | 6.0012 | 5.0052 | 9.0007 | ||||

| 11/2" | 38.001 | 50 | 3.0098 | 3.0042 | 5.0064 | 5.0009 | 8.0034 | ||||

| 2" | 50.008 | 10 | 7.0057 | 6.0082 | 14.0083 | 11.0024 | |||||

| 5" | 127 | 10 | |||||||||

| 13/4" | 44.005 | 50 | 4.0066 | 4.0000 | 6.0061 | 5.0096 | 9.0080 | ||||

| 3" | 76.002 | 10 | 11.0043 | 10.0030 | 22.0055 | 17.0003 | 43.0088 | ||||

| 21/2" | 63.005 | 10 | 9.0050 | 8.0056 | 18.0069 | 14.0013 | |||||

| 4" | 101.006 | 10 | 30.0027 | 22.0082 | 59.0032 | 73.0039 | 87.0016 | ||||

| 31/2" | 88.009 | 10 | 13.0036 | 12.0003 | 26.0041 | 19.0092 | 51.0060 | ||||

| 6" | 152.004 | 10 | |||||||||

Most Common Method

Process

ASTM A312 Stainless Steel Pipes OD Tolerance

| NPS | ASTM A312 Welded Pipes Outside Diameter Tolerance | |||

|---|---|---|---|---|

| + | – | |||

| milimeter | inch | milimeter | inch | |

1/8~1 1 /2 |

0.04 0.08 1.6 2.4 3.2 4.0 4.8 |

1/64(0.0015) |

0.08 |

1/32(0.0031) |

ASTM A312 Stainless Steel Pipes WT Tolerance %

| NPS | ASTM A312 Welded Pipes WT Tolerance, % |

|

|---|---|---|

| – | + | |

| 3~18, t/D≤ 5% | 12.5 | 22.5 |

| ≥ 20, seamless, t/D≤ 5% | 12.5 | 22.5 |

| 1/8-2 1 /2 | 12.5 | 20.0 |

| ≥ 20, welded | 12.5 | 17.5 |

| 3~18, t/D> 5% | 12.5 | 15.0 |

| ≥ 20, seamless, t/D> 5% | 12.5 | 15.0 |