Increased ambient temperatures may hasten the pace of degradation in situations where corrosion by oxidation occurs. Low-chromium stainless steels are more susceptible to oxidation corrosion. Additionally, UNS S31609 ERW Pipe's increased carbon content allows for a delay in the oxidation process. The alloy's tolerance for high temperatures likewise rises as the carbon concentration is increased. As a result, the pace of degradation is slowed.

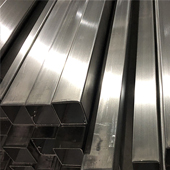

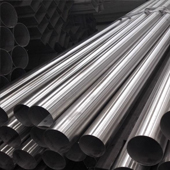

As a result, the high carbon variant of Stainless Steel 316H Seamless Pipe is well suited for applications where general corrosion resistance is essential as well as high-temperature settings. The ASTM A312 TP 316H Rectangular Pipe is well suited for high pressure applications because of its material. The use of an ASTM A312 TP 316H Square Pipe is common in a number of situations where the applications require a combination of high pressure and extreme temperatures up to 500oC.

These circumstances are typical in nuclear power facilities. Therefore, AISI 316H schedule 40 pipe is preferred by the power generating industry as well as the maritime and chemical processing industries. Aside from long-term investment considerations, adopting SS 316H Welded Pipe is worthwhile because to its superior mechanical qualities and corrosion resistance.

| Standard Specification | ASTM A 312/ ASME SA 312/ A790/ SA790/ EN10216-5 |

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 - 60 mm |

| SS Seamless Pipe Length |

|

| Seamless SS Pipe Surface Finish | Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements |

| Standard | JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST |

| Manufacturing types | Seamless, Welded, ERW, EFW |

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |

| Manufacturing Technology | Hot / Cold Formed |

| Other Grades | SS 446 |

| Inspection, Test Reports | EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection |

| Technique | Cold Rolled Hot Rolled |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16.0 | 2.00 | 10.0 | – |

| max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | – |

| Grade | Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Elec Resistivity (nΩ.m) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 0-100°C | 0-315°C | 0-538°C | At 100°C | At 500°C | |||||

| 316H | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS 316H | – | S31609 | – | – | – | – | – |

| PIPE SIZE | OD IN INCHES | A.S.A. Pipe Schedules | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5s | 5 | 10s | 10 | 40s & Sth. | 40 | 60 | 80s & E.H. | 80 | 120 | 160 | DBL E.H. | ||

| 1/8 | .405 | .035.1383 | .049.1863 | .049.1863 | .068.2447 | 068.2447 | 0.95.3145 | 0.95.3145 | |||||

| 1/4 | .540 | .049.2570 | .065.3297 | .065.3297 | .088.4248 | 088.4248 | .119.5351 | .119.5351 | |||||

| 3/8 | .675 | .049.3276 | .065.4235 | .065.4235 | .091.5676 | .091.5676 | .126.7338 | .126.7338 | |||||

| 1/2 | .840 | .065.5383 | .065.5383 | .083.6710 | .083.6710 | .109.8510 | .109.8510 | .1471.088 | .1471.088 | .1871.304 | .2941.714 | ||

| 3/4 | 1.050 | .065.6838 | .065.6838 | .083.8572 | .083.8572 | .1131.131 | .1131.131 | .1541.474 | .1541.474 | .2181.937 | .3082.441 | ||

| 1 | 1.315 | .065.8678 | .065.8678 | .1091.404 | .1091.404 | .1331.679 | .1331.679 | .1792.172 | .1792.172 | .2502.844 | .3583.659 | ||

| 1-1/4 | 1.660 | .0651.107 | .0651.107 | .1091.806 | .1091.806 | .1402.273 | .1402.273 | .1912.997 | .1912.997 | .2503.765 | .3825.214 | ||

| 1-1/2 | 1.900 | .0651.274 | .0651.274 | .1092.085 | .1092.085 | .1452.718 | .1452.718 | .2003.631 | .2003.631 | .2814.859 | .4006.408 | ||

| 2 | 2.375 | .0651.604 | .0651.604 | .1092.638 | .1092.638 | .1543.653 | .1543.653 | .2185.022 | .2185.022 | .3437.444 | .4369.029 | ||

| 2-1/2 | 2.875 | .0832.475 | .0832.475 | .1203.531 | .1203.531 | .2035.793 | .2035.793 | .2767.661 | .2767.661 | .37510.01 | .55213.70 | ||

| 3 | 3.500 | .0833.029 | .0833.029 | .1204.332 | .1204.332 | .2167.576 | .2167.576 | .30010.25 | .30010.25 | .43714.32 | .60018.58 | ||

| 3-1/2 | 4.000 | .0833.472 | .0833.472 | .1204.973 | .1204.973 | .2269.109 | .2269.109 | .31812.51 | .31812.51 | .63622.85 | |||

| 4 | 4.500 | .0833.915 | .0833.915 | .1205.613 | .1205.613 | .23710.79 | .23710.79 | .28112.66 | .33714.98 | .33714.98 | .43719.01 | .53122.51 | .67427.54 |

| 4-1/2 | 5.000 | .24712.53 | .35517.61 | .71032.53 | |||||||||

| 5 | 5.563 | .1096.349 | .1096.349 | .1347.770 | .1347.770 | .25814.62 | .25814.62 | .37520.78 | .37520.78 | .50027.04 | .62532.96 | .75038.55 | |

| 6 | 6.625 | .1097.585 | .1097.585 | .1349.290 | .1349.290 | .28018.97 | .28018.97 | .43228.57 | .43228.57 | .56236.39 | .71845.30 | .86453.16 | |

| 7 | 7.625 | .30123.57 | .50038.05 | .87563.08 | |||||||||

| Medium Type = Wall thickness in inches Bold Type = Steel weight per foot in pounds | |||||||||||||