Although grade 310 stainless steel is an austenitic alloy, it is less ductile than grade 304. But because of its chemical makeup, stainless steel 310 seamless pipe has inherited qualities including high hardenability, wear resistance, and corrosion resistance. The 310h Stainless Steel Welded Pipe also has much greater levels of nickel and chromium. Since grade 310 stainless steel pipe has a medium carbon content, most manufacturers worldwide advise dual certification as 310s/310h because much of their chemistry stays the same, with changes only affecting the carbon atoms.

SS 310 Seamless Pipe is available in two versions: 310S, which is low carbon, and 310H, which is high carbon. Specification Austenitic alloys, like Aisi 310s Welded Pipe, are included in ASTM A312 because they are excellent for high-temperature situations. The Asme Sa 312 Grade 310s/ 310h Square Pipe performs well in settings where the operational temperatures range up to 1150°C in continuous service thanks to the greater nickel content in its alloy. The Astm A312 Tp 310 Erw Pipe slows the onset of corrosion brought on by oxidation, as is the case with alloys possessing a chromium concentration of more than 20%.

However, applications where lowering sulphur atmospheres are frequent are among the industries that benefit from using Uns S31008 Schedule 40 Pipe. Hydrogen sulphide gas, often known as H2S, is frequently present in such atmospheres. Since the Din 1.4845 Rectangular Pipe is resistant to lowering sulphur atmospheres, many manufacturers advise using it because this gas is particularly corrosive.

| Standard Specification | ASTM A 312/ ASME SA 312/ A790/ SA790/ EN10216-5 |

|---|---|

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 - 60 mm |

| SS Seamless Pipe Length |

|

| Seamless SS Pipe Surface Finish | Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements |

| Standard | JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST |

| Manufacturing types | Seamless, Welded, ERW, EFW |

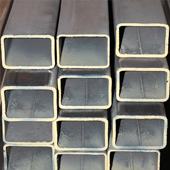

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |

| Manufacturing Technology | Hot / Cold Formed |

| Other Grades | SS 446 |

| Inspection, Test Reports | EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection |

| Technique | Cold Rolled Hot Rolled |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.25 max | 2 max | 1.50 max | 0.045 max | 0.030 max | 24 - 26 | - | 19 - 22 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| Standard | SS 310 |

|---|---|

| WERKSTOFF NR. | 1.4845 |

| UNS | S31000 |

| PIPE SIZE | OD IN INCHES | A.S.A. Pipe Schedules | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5s | 5 | 10s | 10 | 40s & Std. | 40 | 60 | 80s & E.H. | 80 | 120 | 160 | DBL E.H. | ||

| 1/8 | .405 | .035.1383 | .049.1863 | .049.1863 | .068.2447 | 068.2447 | 0.95.3145 | 0.95.3145 | |||||

| 1/4 | .540 | .049.2570 | .065.3297 | .065.3297 | .088.4248 | 088.4248 | .119.5351 | .119.5351 | |||||

| 3/8 | .675 | .049.3276 | .065.4235 | .065.4235 | .091.5676 | .091.5676 | .126.7338 | .126.7338 | |||||

| 1/2 | .840 | .065.5383 | .065.5383 | .083.6710 | .083.6710 | .109.8510 | .109.8510 | .1471.088 | .1471.088 | .1871.304 | .2941.714 | ||

| 3/4 | 1.050 | .065.6838 | .065.6838 | .083.8572 | .083.8572 | .1131.131 | .1131.131 | .1541.474 | .1541.474 | .2181.937 | .3082.441 | ||

| 1 | 1.315 | .065.8678 | .065.8678 | .1091.404 | .1091.404 | .1331.679 | .1331.679 | .1792.172 | .1792.172 | .2502.844 | .3583.659 | ||

| 1-1/4 | 1.660 | .0651.107 | .0651.107 | .1091.806 | .1091.806 | .1402.273 | .1402.273 | .1912.997 | .1912.997 | .2503.765 | .3825.214 | ||

| 1-1/2 | 1.900 | .0651.274 | .0651.274 | .1092.085 | .1092.085 | .1452.718 | .1452.718 | .2003.631 | .2003.631 | .2814.859 | .4006.408 | ||

| 2 | 2.375 | .0651.604 | .0651.604 | .1092.638 | .1092.638 | .1543.653 | .1543.653 | .2185.022 | .2185.022 | .3437.444 | .4369.029 | ||

| 2-1/2 | 2.875 | .0832.475 | .0832.475 | .1203.531 | .1203.531 | .2035.793 | .2035.793 | .2767.661 | .2767.661 | .37510.01 | .55213.70 | ||

| 3 | 3.500 | .0833.029 | .0833.029 | .1204.332 | .1204.332 | .2167.576 | .2167.576 | .30010.25 | .30010.25 | .43714.32 | .60018.58 | ||

| 3-1/2 | 4.000 | .0833.472 | .0833.472 | .1204.973 | .1204.973 | .2269.109 | .2269.109 | .31812.51 | .31812.51 | .63622.85 | |||

| 4 | 4.500 | .0833.915 | .0833.915 | .1205.613 | .1205.613 | .23710.79 | .23710.79 | .28112.66 | .33714.98 | .33714.98 | .43719.01 | .53122.51 | .67427.54 |

| 4-1/2 | 5.000 | .24712.53 | .35517.61 | .71032.53 | |||||||||

| 5 | 5.563 | .1096.349 | .1096.349 | .1347.770 | .1347.770 | .25814.62 | .25814.62 | .37520.78 | .37520.78 | .50027.04 | .62532.96 | .75038.55 | |

| 6 | 6.625 | .1097.585 | .1097.585 | .1349.290 | .1349.290 | .28018.97 | .28018.97 | .43228.57 | .43228.57 | .56236.39 | .71845.30 | .86453.16 | |

| 7 | 7.625 | .30123.57 | .50038.05 | .87563.08 | |||||||||

| Medium Type = Wall thickness in inches Bold Type = Steel weight per foot in pounds | |||||||||||||