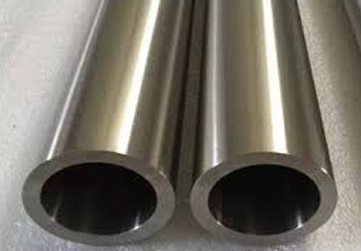

Alloy 904L is the most resistant stainless steel, even though most of them show resistance to sulfuric acid in a range of concentrations. So, for applications that specifically use sulfuric acid or in those where sulfuric acid is a byproduct, the majority of manufacturers advise using grade 904L stainless steel seamless pipe. Sulfuric acid is a highly corrosive fluid that dissolves things at greater concentrations. Therefore, employing STM B673 UNS N08904 ERW Pipe, which is a robust material, is appropriate for these applications. Due to the addition of copper to the alloy, sulfuric acid resistance has been identified as a contributing factor.

Copper is the material of choice for engineering because it makes UNS N08904 schedule 40 pipe resistant to the sodium chloride found in marine conditions. Because of its abilities to resist corrosion, the ASTM A312 tp 904L material is classified as a super austenitic stainless steel alloy. The ASME SB677 TP 904L Square Pipe offers superior resistance to localised attack, especially from corrosion forms like pitting and crevice corrosion, because the alloy has a larger amount of molybdenum in its composition. Contrary to the more robust grade of stainless steel 904L seamless pipe, traditional alloys are more susceptible to pitting and crevice corrosion when chlorides and some reductive acids are present.

Due to the alloy's improved weldability and lower carbon content, ASTM A312 tp 904L Welded Pipe production is simplified. Due to the decreased carbon content, the formation of carbide precipitates on the DIN 1.4539 Rectangular Pipe is discouraged, preventing welding issues like intergranular corrosion.

| Standard Specification | ASTM A 312/ ASME SA 312/ A790/ SA790/ EN10216-5 |

|---|---|

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 - 60 mm |

| SS Seamless Pipe Length |

|

| Standard | JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST |

| Manufacturing types | Seamless, Welded, ERW, EFW |

| Seamless SS Pipe Surface Finish | Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements |

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |

| Manufacturing Technology | Hot / Cold Formed |

| Other Grades | SS 446 |

| Technique | Cold Rolled Hot Rolled |

| Inspection, Test Reports | EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection |

| Tensile Strength | 520-720 |

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 460 | 68 | 0.11 |

| 100 | 485 | 200 | 0.12 |

| 200 | 515 | 400 | 0.12 |

| 300 | 545 | 600 | 0.13 |

| 400 | 570 | 800 | 0.14 |

| 500 | 590 | 1000 | 0.14 |

| 600 | 605 | 1200 | 0.15 |

| 700 | 615 | 1300 | 0.15 |

| Temperature | Comparison to other High Temperature Pipe | ||||

|---|---|---|---|---|---|

| °F | °C | Alloy 254 | UNS C69100 Temper TF00 | Type 904L | Alloy 825 |

| 200 | 93 | 0.88 | 1.00 | 0.82 | 1.00 |

| 300 | 149 | 0.79 | 1.00 | 0.74 | 0.95 |

| 400 | 204 | 0.73 | 0.96 | 0.68 | 0.90 |

| 500 | 260 | 0.69 | 0.63 | 0.87 | |

| 600 | 315 | 0.66 | 0.58 | 0.84 | |

| 700 | 371 | 0.64 | 0.56 | 0.81 | |

| 800 | 426 | 0.79 | |||

| Nominal size [inches] | Outside diameter (OD) [inches] | Outside diameter (OD) [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

|---|---|---|---|---|---|---|

| 1/8" NPS 6 | 0.41 | 10.3 | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4" NPS 8 | 0.54 | 13.7 | 0.088 | 2.24 | 0.42 | 0.63 |

| 3/8" NPS 10 | 0.68 | 17.1 | 0.091 | 2.31 | 0.57 | 0.84 |

| 1/2" NPS 15 | 0.84 | 21.3 | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4" NPS 20 | 1.05 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1" NPS 25 | 1.32 | 33.4 | 0.133 | 3.38 | 1.68 | 2.5 |

| 1 1/4" NPS 32 | 1.66 | 42.2 | 0.14 | 3.56 | 2.27 | 3.39 |

| 1 1/2" NPS 40 | 1.9 | 48.3 | 0.145 | 3.68 | 2.72 | 4.05 |

| 2" NPS 50 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2" NPS 65 | 2.875 | 73.0 | 0.203 | 5.16 | 5.79 | 8.63 |

| 3" NPS 80 | 3.5 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2" NPS 90 | 4.0 | 101.6 | 0.226 | 5.74 | 9.11 | 13.57 |

| 4" NPS 100 | 4.5 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 5" NPS 125 | 5.563 | 141.3 | 0.258 | 6.55 | 14.62 | 21.77 |

| 6" NPS 150 | 6.625 | 168.3 | 0.28 | 7.11 | 18.97 | 28.26 |

| 8" NPS 200 | 8.625 | 219.1 | 0.322 | 8.18 | 28.55 | 42.55 |

| 10" NPS 250 | 10.75 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 12" NPS 300 | 12.75 | 323.8 | 0.406 | 10.31 | 53.52 | 79.73 |

| 14" NPS 350 | 14.0 | 355.6 | 0.437 | 11.13 | 54.57 | 94.55 |

| 16" NPS 400 | 16.0 | 406.4 | 0.5 | 12.7 | 82.77 | 123.3 |

| 18" NPS 450 | 18.0 | 457.0 | 0.562 | 14.27 | 104.67 | 155.8 |

| 20" NPS 500 | 20.0 | 508.0 | 0.594 | 15.09 | 123.11 | 183.42 |

| 24" NPS 600 | 24.0 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 32" NPS 800 | 32.0 | 813.0 | 0.688 | 17.48 | 230.08 | 342.91 |

| Nominal | O.D. Inches | 10s | 10 | 40s & Std | 40 | 80s & E.H. | 80 | 160 |

|---|---|---|---|---|---|---|---|---|

| 1/8 | .405 | .049 | .049 | .068 | .068 | .095 | .095 | |

| 1/4 | .540 | .065 | .065 | .088 | .088 | .119 | .119 | |

| 3/8 | .675 | .065 | .065 | .091 | .091 | .126 | .126 | |

| 1/2 | .840 | .083 | .083 | .109 | .109 | .147 | .147 | .187 |

| 3/4 | 1.050 | .083 | .083 | .113 | .113 | .154 | .154 | .218 |

| 1 | 1.315 | .109 | .109 | .133 | .133 | .179 | .179 | .250 |

| 1 1/4 | 1.660 | .109 | .109 | .140 | .140 | .191 | .191 | .250 |

| 1 1/2 | 1.900 | .109 | .109 | .145 | .145 | .200 | .200 | .281 |

| 2 | 2.375 | .109 | .109 | .154 | .154 | .218 | .218 | .343 |

| 2 1/2 | 2.875 | .120 | .120 | .203 | .203 | .276 | .276 | .375 |

| 3 | 3.500 | .120 | .120 | .216 | .216 | .300 | .300 | .437 |

| 3 1/2 | 4.000 | .120 | .120 | .226 | .226 | .318 | .318 | |

| 4 | 4.500 | .120 | .120 | .237 | .237 | .337 | .337 | .531 |

| 4 1/2 | 5.000 | .247 | .355 | |||||

| 5 | 5.563 | .134 | .134 | .258 | .258 | .375 | .375 | .625 |

| 6 | 6.625 | .134 | .134 | .280 | .280 | .432 | .432 | .718 |

| 7 | 7.625 | .301 | .500 | |||||

| 8 | 8.625 | .148 | .148 | .322 | .322 | .500 | .500 | .906 |

| 9 | 9.625 | .342 | .500 | |||||

| 10 | 10.750 | .165 | .165 | .365 | .365 | .500 | .593 | 1.125 |

| 11 | 11.750 | .375 | .500 | |||||

| 12 | 12.750 | .180 | .180 | .375 | .406 | .500 | .687 | 1.312 |

| 14 | 14.000 | .188 | .250 | .375 | .437 | .500 | .750 | 1.406 |

| 16 | 16.000 | .188 | .250 | .375 | .500 | .500 | .843 | 1.593 |

| 18 | 18.000 | .188 | .250 | .375 | .562 | .500 | .937 | 1.781 |

| Stainless Steel 904L Pipe | 4 inch Stainless Steel 1.4539 Seamless Pipe |

| Stainless Steel 1.4539 Pipes | SS B677 TP904L Welded Pipes |

| 904L Stainless Steel Seamless Steel Pipe | ASTM B677 TP 904L Cold Drawn Welded Pipes |

| Stainless Steel 1.4539 Welded Pipe | UNS N08904 Cold Drawn Pipes |

| SS B677 TP904L ERW Pipe | Schedule 5S 904L SS Seamless Pipes |

| UNS N08904 EFW Pipe | Schedule 40 ASME SB677 TP 904L Pipe |

| 904L SS Cold Drawn Seamless Pipes | SS B677 TP904L Precision Pipe |

| Stainless Steel 904L Seamless Steel Precision Pipe | High pressure 904L Stainless Steel Pipe |

| ASME SB677 TP 904L Cold Drawn Seamless Pipes | 904L SS Electropolished Pipe |

| SS B677 TP904L Custom Pipe | Stainless Steel 904L Cold Drawn Pipes |

| ASTM B677 TP 904L Round Pipe | UNS N08904 Exhaust Pipe |

| 904L SS Square Pipe | ASTM B677 TP 904L Thin Wall Pipe |

| ASTM B677 TP 904L Rectangular Pipe | Small diameter ASME SB677 TP 904L pipe |

| NPS | Outside Diameter (OD) | Wall Thickness (WT) | Weight | Weight | |||

|---|---|---|---|---|---|---|---|

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2" | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4" | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1" | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4" | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2" | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2" | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2" | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3" | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4" | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6" | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8" | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10" | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12" | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14" | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 | 30 STD |

93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 | 40 XHY |

123.289 | 82.770 | |||

| 18" | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20" | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24" | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30" | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36" | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

0.688 |

17.475 | 386.487 | 259.467 | ||||

0.750 |

19.050 | 420.576 | 282.353 | ||||

| 42" | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48" | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

| Element | Min | Max |

|---|---|---|

| C | - | 0.2 |

| Mn | - | 2 |

| Ni | 23 | 28 |

| Cr | 19 | 23 |

| S | - | 0.3 |

| Mo | 4 | 5 |

| N | - | 0.1 |

| Cu | 1 | 2 |

| P | - | 0.03 |

| Si | - | 0.7 |

| Temper | Annealed | |

|---|---|---|

| Tensile Rm | 71 | ksi (min) |

| Tensile Rm | 490 | MPa (min) |

| R.p. 0.2% Yield | 32 | ksi (min) |

| R.p. 0.2% Yield | 220 | MPa (min) |

| Elongation (2” or 4D gl) | 35 | % (min) |

| Specific Heat (0-100°C) | 450 | J.kg-1.°K-1 |

| Thermal Conductivity | 11.5 | W.m -1.°K-1 |

| Thermal Expansion | 15.8 | mm/m/°C |

| Modulus Elasticity | 190 | GPa |

| Electrical Resistivity | 9.52 | μohm/cm |

| Density | 7.95 | g/cm3 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | X1NiCrMoCu25-20-5 | 1.4539 | – | – | SUS 890L |