Grade 321 is a heat-resistant alloy that is a member of the austenitic family of stainless steels. Both stainless steel grade 304 and stainless steel 321 seamless pipe share a similar chemical composition. The difference between them can be explained by the fact that grade 321 has roughly five times as much titanium as alloy 304 does carbon. The rate of carbide precipitation in ASTM A312 TP 321 ERW Pipe significantly decreases when titanium is added to the alloy, especially after welding.

Furthermore, even after the SS 321 Welded Pipe has been exposed to temperatures between 800°F and 1500°F, the rate of alloy breakdown is also slowed down. The amount of carbon in the alloy of a UNS S32100 schedule 40 pipe could be raised, similar to the majority of austenitic stainless steel alloys in the 300 series. While the outcome is comparable to that of its other austenitic stainless steel competitors, this specific alloy's mechanical qualities increase dramatically. One improvement is shown in the ASME SA 312 Grade 321H Square Pipe's ability to resist creep.

IThe stress rupture characteristics and low-temperature toughness of the 321/321H stainless steel round pipe are significantly higher than those of grades 304 and 304L. Due to its carbon concentration, grade 321 and 321H are both capable of dual certification. Since DIN 1.4541 Rectangular Pipe can tolerate temperatures as high as 1500°F without succumbing to oxidation, its oxidation resistance is highly regarded.

| Standard Specification | ASTM A 312/ ASME SA 312/ A790/ SA790/ EN10216-5 |

|---|---|

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 - 60 mm |

| SS Seamless Pipe Length |

|

| Seamless SS Pipe Surface Finish | Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements |

| Standard | JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST |

| Manufacturing types | Seamless, Welded, ERW, EFW |

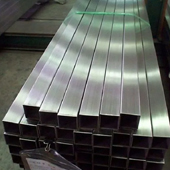

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |

| Manufacturing Technology | Hot / Cold Formed |

| Other Grades | SS 446 |

| Inspection, Test Reports | EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection |

| Technique | Cold Rolled Hot Rolled |

| ASTM A312 TP 321 Welded Pipe | High pressure UNS S32100 Pipe |

| SS A312 TP321 Custom Pipe | Schedule 40 321 SS Pipe |

| UNS S32100 Seamless Steel Pipe | Schedule 5S Stainless Steel 1.4541 Seamless Pipes |

| ASME SA312 TP 321 EFW Pipe | Stainless Steel 321 Cold Drawn Pipes |

| Stainless Steel 1.4541 Cold Drawn Seamless Pipes | 4 inch ASTM A312 TP 321 Seamless Pipe |

| Stainless Steel 321 Pipe | SS A312 TP321 Welded Pipes |

| Stainless Steel 321 Seamless Steel Precision Pipe | ASME SA312 TP 321 Cold Drawn Pipes |

| SS A312 TP321 ERW Pipe | 321 Stainless Steel Cold Drawn Welded Pipes |

| ASTM A312 TP 321 Pipes | Stainless Steel 1.4541 Electropolished Pipe |

| 321 SS Cold Drawn Seamless Pipes | SS A312 TP321 Precision Pipe |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) - 0.70 max |

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

|---|---|---|---|---|

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |