The tubes used in heat exchanger systems contribute to the exchange of heat between two fluids or, in certain situations, to the cooling of those fluids. Additionally, because they provide their user with a number of advantages, several Stainless Steel Shell And Tube Heat Exchanger Manufacturers advocate them. A stainless steel heat exchanger tube may be utilised in a variety of industrial processes, from the removal of process heat and preheating of feed water to the evaporation of liquid or steam. The great strength and corrosion resistance of the alloy, along with its outstanding performance, lead the manufacturers of spiral heat exchangers to advise using it in a variety of industries, including hydraulics and the marine sector.

Plate And Frame Heat Exchanger Manufacturers advise utilising these tubes to cool hydraulic and lubricant oil in hydraulic applications. The Stainless Steel Heat Exchanger Shell and Tube can be used for a variety of purposes in addition to those listed above, including cooling down engines, compressors, turbines, and vapour or steam condensation processes. Despite having a variety of possibilities, including copper, copper-nickel, carbon steel, brass alloys, or even titanium alloys, Air Cooled Heat Exchanger Manufacturers prefer employing stainless steel.

The Stainless Steel Fin Tube Heat Exchanger can be produced in any grade, depending on the requirements of the application, because stainless steel is widely available and offers its users resistance to corrosion. However, if the application requires a lower cost, the suppliers of stainless steel heat exchanger tubes may advise the buyer to acquire an exchanger tube made of grade 304, a more affordable grade of stainless steel.

Compare Stainless Steel Heat Exchanger tube Price with Stainless Steel Boiler Tube price list

| Standard | ASTM A249/ ASME SA 249, ASTM A269/ ASME SA 269, ASTM A789/ ASME SA 789 |

| grades | TP304 / 304L, TP316, TP316L, TP 309S, TP310S, TP321, TP321H, TP347, TP347 H, Duplex 2205 / S31803 |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Size Range | 6.53 to127 mm |

| Length | up to 20 m (65.62 ft) or Custom as required |

| Bending radii | 1.25 x OD up to 1700mm |

| Wall Thickness Range | 0.5 - 5 mm |

| Tolerance | +/-0.05 Mm |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Marking on Stainless Steel Heat Exchanger Tubes |

|

| Test Certificate |

|

| Packaging | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers' request |

| Port | Mumbai, India |

| Uses & Application |

|

| Heat exchanging area(m²) | Diameter of Tube(mm) | Diameter of pipe(mm) | Design Pressure(Mpa) |

|---|---|---|---|

| 2.04~3.47 | 1500~2500 | 273 | 0.6/1.0 |

| 2.63~3.42 | 1500~3000 | 325 | 0.6/1.0 |

| 8.36~18.26 | 1500~3200 | 400 | 0.6/1.0 |

| 18.48~30.56 | 2000~3200 | 500 | 0.6/1.0 |

| 35.12~49.62 | 2500~3500 | 600 | 0.6/1.0 |

| Stainless Steel Tube for Heat Exchanger | Egypt, Malaysia, Mexico, Los Alamos -Mexico |

| Heat Exchanger Welding Tube Mill Line | Netherlands, Sweden, Russia, Malaysia |

| Stainless Steel Tube for Evaporater Muffler Heat Exchanger Boiler 300 Series | UK, Dammam -KSA, Poland, Philippines |

| Stainless Steel Shell and Tube Heat Exchanger for Thermal Oil and Water | United Arab Emirates (UAE), Europe, Norway, Romania |

| Stainless Steel Corrugated Tube for Heat Exchanger Power Plants 300 Series | United Kingdom -UK, Singapore, Malaysia, NY 12203 (USA) |

| Stainless Steel Heat Exchanger Bolier Seamless Tube | Malaysia, Czechia, Japan, Thailand |

| Stainless Steel Extruded Fin Tube for Heat Exchanger | UAE, Singapore, Malaysia, Italy |

| Sanitary Design Stainless Steel Double Tube Plate Heat Exchanger | China, Malaysia, Colombia, Bangladesh |

| Austenitic Stainless Steel U Tube for Heat Exchanger and Boiler | Philippines, South Africa, Taiwan, Kuwait |

| Full Stainless Steel Shell and Tube Heat Exchanger | Chile, Philippines, Iran, Canada |

| economic fin tube air heat exchanger | Singapore, Qatar, Malaysia, Europe |

| 100kw stainless steel finned tube heat exchanger for trailers | Belgium, Philippines, Indonesia, UK |

| stainless steel finned tube coil steam heat exchanger for dryer | Malaysia, Germany, Turkey |

| Steam to Air Heat Exchanger with Finned Tube Stainless Steel | Thailand, Oman, France, Hong Kong |

| Stainless Steel Coil Tube Used for Heat Exchanger | Brazil, UK, Saudi Arabia (KSA), Spain |

| Stainless Steel Swimming Pool Shell Tube Water Heat Exchanger | Malaysia, Bahrain, South Korea, Singapore |

| 40 Litre Stainless Steel Air Pressure Vessel U Tube Heat Exchanger | Finland, Dubai, USA, Malaysia |

| Stainless steel finned tube bundle heat exchanger | Nigeria, Ellington -United States, Australia, Canada |

| 100mm Stainless Steel Fin Tube for Heat Exchanger | Singapore, UAE, South Africa, Europe |

| BWG | BWG | BWG | BWG | BWG | BWG | BWG | BWG | ||

| 25 | 22 | 20 | 18 | 16 | 14 | 12 | 10 | ||

| WT mm | WT mm | WT mm | WT mm |

WT mm | WT mm | WT mm | WT mm |

||

| Outside Diameter | Outside Diameter | 0.508 | 0.71 | 0.89 | 1.24 | 1.65 | 2.11 | 2.77 | 3.40 |

| mm | inch | kg/m | kg/m | kg/m | kg/m | kg/m | kg/m | kg/m | |

| 6.35 | 1/4 | 0.081 | 0.109 | 0.133 | 0.174 | 0.212 | |||

| 9.53 | 3/8 | 0.126 | 0.157 | 0.193 | 0.257 | 0.356 | 0.429 | ||

| 12.7 | 1/2 | 0.214 | 0.263 | 0.356 | 0.457 | 0.612 | 0.754 | ||

| 15.88 | 5/8 | 0.271 | 0.334 | 0.455 | 0.588 | 0.796 | 0.995 | ||

| 19.05 | 3/4 | 0.327 | 0.405 | 0.553 | 0.729 | 0.895 | 1.236 | ||

| 25.4 | 1 | 0.44 | 0.546 | 0.75 | 0.981 | 1.234 | 1.574 | 2.05 | |

| 31.75 | 1 1/4 | 0.554 | 0.688 | 0.947 | 1.244 | 1.574 | 2.014 | 2.641 | |

| 38.1 | 1 1/2 | 0.667 | 0.832 | 1.144 | 1.514 | 1.904 | 2.454 | 3.233 | |

| 44.5 | 1 3/4 | 1.342 | 1.774 | 2.244 | 2.894 | 3.5 | |||

| 50.8 | 2 | 1.549 | 2.034 | 2.574 | 3.334 | 4.03 | |||

| 63.5 | 2 1/2 | 1.949 | 2.554 | 3.244 | 4.214 | 5.13 | |||

| 76.2 | 3 | 2.345 | 3.084 | 3.914 | 5.094 | 6.19 | |||

| 88.9 | 3 1/2 | 2.729 | 3.609 | 4.584 | 5.974 | 7.27 | |||

| 101.6 | 4 | 4.134 | 5.254 | 6.854 | 8.35 | ||||

| 114.3 | 4 1/2 | 4.654 | 5.924 | 7.734 | 9.43 |

| EN 1.4404 3/8" 1/2" 2/4" stainless steel heat exchanger tube | Stainless steel 304 tube heat exchanger |

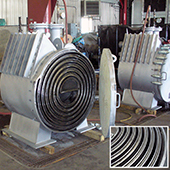

| AISI 316L Coiled heat exchanger Tube | SS 316 welded spiral heat exchanger |

| Stainless Steel Shell and Heat Exchanger Tubes | ASTM A213 cold drawn tp316l stainless steel Heat Exchanger seamless tube |

| Stainless steel cooling tube for heat exchanger | AISI 304 1" BWG 16 stainless steel heat exchanger tube |

| Stainless steel cooling coil tube for heat exchanger | SUS 304L Seamless stainless Steel Coil heat exchanger Tube |

| Welded Stainless Steel Heat Exchanger Tubes | 316L stainless steel heat exchanger tubes |

| Stainless Steel Type | ASTM | Equivalent Standard | |||

|---|---|---|---|---|---|

| UNS | Grads (TP) | EN / Din | Afnor (NF) | JIS | |

| Austenitic | S30400 | 304 | 1.4301 | Z 6 CN 18.09 | SUS 304 |

| S30403 | 304L | 1.4306 | Z 2 CN 18.10 | SUS 304L | |

| S31600 | 316 | 1.4401 | Z 6 CND 17.11 | SUS 316 | |

| S31603 | 316L | 1.4404 | Z 2 CND 17.12 | SUS 316L | |

| S31635 | 316Ti | 1.4571 | Z 2 CND 17.12 | - | |

| S32100 | 321 | 1.4541 | Z 6 CNT 18.10 | SUS 321 | |

| S34700 | 347 | 1.455 | Z 6 CNNb 18.10 | SUS 347 | |

| S30409 | 304H | 1.4948 | Z 6 CN 19.10 | SUS 304H | |

| S31609 | 316H | 1.4919 | Z 10 CND 18.10 | SUS 316H | |

| S32109 | 321H | 1.4941 | Z 10 CND 18.10 | SUS 321H | |

| Ferritic | S40500 | 405 | 1.4002 | Z 6 CAL 13 | SUS 405 |

| S41000 | 410 | 1.4002 | Z 12 C 13 | SUS 410 | |

| S43000 | 430 | 1.4016 | Z 10 C 17 | SUS 430 | |

| Duplex | S31803 | - | 1.4462 | Z 2 CND 22.06 | - |

| S32750 | 2507 | 1.4410 | Z 5 CND 20.12 | - | |

| S32760 | - | 1.4501 | - | - | |

| Standard | SIZES OD INCHES | Tolerances Chart | |||

|---|---|---|---|---|---|

| O.D. | Wall Thickness | ||||

| PLUS (+) | MINUS (-) | PLUS (+) | MINUS (-) | ||

| ASTM-A-213 | Under 1.000 | .004" | .004" | 20% | 0% |

| ASME-SA-213 | 1.000 to 1.500 | .006" | .005" | 20% | 0% |

| Cold Finished Seamless | 1.501 to 1.999 | .008" | .008" | 22% | 0% |

| Heat Exchanger Tube | 2.000 to 2.499 | .010" | .010" | 22% | 0% |

| Minimum Wall | 2.500 to 2.999 | .012" | .012" | 22% | 0% |

| 3.000 to 4.000 | .015" | .015" | 22% | 0% | |

| 4.001 to 5.000 | .015" | .025" | 22% | 0% | |

| Grade | Properties | ||

|---|---|---|---|

| Tensile Stress ≥ MPa | Yield Strength ≥ MPa | Elongation ≥ % | |

| T12 | 415 | 220 | 30 |

| TP304 | 515 | 205 | 35 |

| TP304L | 458 | 170 | 35 |

| TP316 | 515 | 205 | 35 |

| TP316L | 485 | 170 | 35 |

| TP317 | 515 | 205 | 35 |

| TP317L | 515 | 205 | 35 |

| TP321 | 515 | 205 | 35 |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Heat Exchanger - T316/316l SS For Tubing | 220,715 | 2977.38 | 2505.17 |

| Heat Exchanger - T316/316l SS For Tubing | 75,704 | 1021.23 | 859.26 |

| Heat Exchanger - T316/316l SS For Tubing | 220,715 | 2977.38 | 2505.17 |

| Heat Exchanger - T316/316l SS For Tubing | 75,704 | 1021.23 | 859.26 |

| Heat Exchanger - T316/316l SS For Tubing | 36,882 | 497.53 | 418.62 |

| OD inches | Ave. Wall inches | D/t Ratio | ID inches | Tube Cross Sectional Area (in2) | Internal Area (in2) |

|---|---|---|---|---|---|

| 0.250 | 0.020 | 12.50 | 0.210 | 0.0145 | 0.0346 |

| 0.250 | 0.028 | 8.93 | 0.194 | 0.0195 | 0.0296 |

| 0.250 | 0.035 | 7.14 | 0.180 | 0.0236 | 0.0254 |

| 0.250 | 0.049 | 5.10 | 0.152 | 0.0309 | 0.0181 |

| 0.250 | 0.065 | 3.85 | 0.120 | 0.0378 | 0.0113 |

| 0.375 | 0.020 | 18.75 | 0.335 | 0.0223 | 0.0881 |

| 0.375 | 0.028 | 13.39 | 0.319 | 0.0305 | 0.0799 |

| 0.375 | 0.035 | 10.71 | 0.305 | 0.0374 | 0.0731 |

| 0.375 | 0.049 | 7.65 | 0.277 | 0.0502 | 0.0603 |

| 0.375 | 0.065 | 5.77 | 0.245 | 0.0633 | 0.0471 |

| 0.500 | 0.020 | 25.00 | 0.460 | 0.0302 | 0.1662 |

| 0.500 | 0.028 | 17.86 | 0.444 | 0.0415 | 0.1548 |

| 0.500 | 0.035 | 14.29 | 0.430 | 0.0511 | 0.1452 |

| 0.500 | 0.049 | 10.20 | 0.402 | 0.0694 | 0.1269 |

| 0.500 | 0.065 | 7.69 | 0.370 | 0.0888 | 0.1075 |

| 0.500 | 0.083 | 6.02 | 0.334 | 0.1087 | 0.0876 |

| 0.625 | 0.020 | 31.25 | 0.585 | 0.0380 | 0.2688 |

| 0.625 | 0.028 | 22.32 | 0.569 | 0.0525 | 0.2543 |

| 0.625 | 0.035 | 17.86 | 0.555 | 0.0649 | 0.2419 |

| 0.625 | 0.049 | 12.76 | 0.527 | 0.0887 | 0.2181 |

| 0.625 | 0.065 | 9.62 | 0.495 | 0.1144 | 0.1924 |

| 0.625 | 0.083 | 7.53 | 0.459 | 0.1413 | 0.1655 |

| 0.625 | 0.095 | 6.58 | 0.435 | 0.1582 | 0.1486 |

| 0.625 | 0.109 | 5.73 | 0.407 | 0.1767 | 0.1301 |

| 0.750 | 0.028 | 26.79 | 0.694 | 0.0635 | 0.3783 |

| 0.750 | 0.035 | 21.43 | 0.680 | 0.0786 | 0.3632 |

| 0.750 | 0.049 | 15.31 | 0.652 | 0.1079 | 0.3339 |

| 0.750 | 0.065 | 11.54 | 0.620 | 0.1399 | 0.3019 |

| 0.750 | 0.083 | 9.04 | 0.584 | 0.1739 | 0.2679 |

| 0.750 | 0.095 | 7.89 | 0.560 | 0.1955 | 0.2463 |

| 0.750 | 0.109 | 6.88 | 0.532 | 0.2195 | 0.2223 |

| 0.750 | 0.120 | 6.25 | 0.510 | 0.2375 | 0.2043 |

| 0.875 | 0.020 | 43.75 | 0.835 | 0.0537 | 0.5476 |

| 0.875 | 0.028 | 31.25 | 0.819 | 0.0745 | 0.5268 |

| 0.875 | 0.035 | 25.00 | 0.805 | 0.0924 | 0.5090 |

| 0.875 | 0.049 | 17.86 | 0.777 | 0.1272 | 0.4742 |

| 0.875 | 0.065 | 13.46 | 0.745 | 0.1654 | 0.4359 |

| 0.875 | 0.083 | 10.54 | 0.709 | 0.2065 | 0.3948 |

| 0.875 | 0.095 | 9.21 | 0.685 | 0.2328 | 0.3685 |

| 0.875 | 0.109 | 8.03 | 0.657 | 0.2623 | 0.3390 |

| 0.875 | 0.120 | 7.29 | 0.635 | 0.2846 | 0.316L7 |

| 1.000 | 0.028 | 35.71 | 0.944 | 0.0855 | 0.6999 |

| 1.000 | 0.035 | 28.57 | 0.930 | 0.1061 | 0.6793 |

| 1.000 | 0.049 | 20.41 | 0.902 | 0.1464 | 0.6390 |

| 1.000 | 0.065 | 15.38 | 0.870 | 0.1909 | 0.5945 |

| 1.000 | 0.083 | 12.05 | 0.834 | 0.2391 | 0.5463 |

| 1.000 | 0.095 | 10.53 | 0.810 | 0.2701 | 0.5153 |

| 1.000 | 0.109 | 9.17 | 0.782 | 0.3051 | 0.4803 |

| 1.000 | 0.120 | 8.33 | 0.760 | 0.3318 | 0.4536 |

| 1.000 | 0.134 | 7.46 | 0.732 | 0.3646 | 0.4208 |

| 1.250 | 0.035 | 35.71 | 1.180 | 0.1336 | 1.0936 |

| 1.250 | 0.049 | 25.51 | 1.152 | 0.1849 | 1.0423 |

| 1.250 | 0.065 | 19.23 | 1.120 | 0.2420 | 0.9852 |

| 1.250 | 0.083 | 15.06 | 1.084 | 0.316L3 | 0.9229 |

| 1.250 | 0.095 | 13.16 | 1.060 | 0.3447 | 0.8825 |

| 1.250 | 0.109 | 11.47 | 1.032 | 0.3907 | 0.8365 |

| 1.250 | 0.120 | 10.42 | 1.010 | 0.4260 | 0.8012 |

| 1.250 | 0.134 | 9.33 | 0.982 | 0.4698 | 0.7574 |

| 1.500 | 0.035 | 42.86 | 1.430 | 0.1611 | 1.6061 |

| 1.500 | 0.049 | 30.61 | 1.402 | 0.2234 | 1.5438 |

| 1.500 | 0.065 | 23.08 | 1.370 | 0.2930 | 1.4741 |

| 1.500 | 0.083 | 18.07 | 1.334 | 0.3695 | 1.3977 |

| 1.500 | 0.095 | 15.79 | 1.310 | 0.4193 | 1.3478 |

| 1.500 | 0.109 | 13.76 | 1.282 | 0.4763 | 1.2908 |

| 1.500 | 0.120 | 12.50 | 1.260 | 0.5202 | 1.2469 |

| 1.500 | 0.134 | 11.19 | 1.232 | 0.5750 | 1.1921 |

| 1.500 | 0.148 | 10.14 | 1.204 | 0.6286 | 1.1385 |

| 1.750 | 0.035 | 50.00 | 1.680 | 0.1886 | 2.2167 |

| 1.750 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 1.750 | 0.065 | 26.92 | 1.620 | 0.3441 | 2.0612 |

| 1.750 | 0.083 | 21.08 | 1.584 | 0.4347 | 1.9706 |

| 1.750 | 0.095 | 18.42 | 1.560 | 0.4939 | 1.9113 |

| 1.750 | 0.109 | 16.06 | 1.532 | 0.5619 | 1.8433 |

| 1.750 | 0.120 | 14.58 | 1.510 | 0.6145 | 1.7908 |

| 1.750 | 0.134 | 13.06 | 1.482 | 0.6803 | 1.7250 |

| 1.750 | 0.148 | 11.82 | 1.454 | 0.7449 | 1.6604 |

| 1.750 | 0.165 | 10.61 | 1.420 | 0.8216 | 1.5837 |

| 2.000 | 0.035 | 57.14 | 1.930 | 0.2161 | 2.9255 |

| 2.000 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 2.000 | 0.065 | 30.77 | 1.870 | 0.3951 | 2.7465 |

| 2.000 | 0.083 | 24.10 | 1.834 | 0.4999 | 2.6417 |

| 2.000 | 0.095 | 21.05 | 1.810 | 0.5685 | 2.5730 |

| 2.000 | 0.109 | 18.35 | 1.782 | 0.6475 | 2.4941 |

| 2.000 | 0.120 | 16.67 | 1.760 | 0.7087 | 2.4328 |

| 2.000 | 0.134 | 14.93 | 1.732 | 0.7855 | 2.3561 |

| 2.000 | 0.148 | 13.51 | 1.704 | 0.8611 | 2.2805 |

| 2.000 | 0.165 | 12.12 | 1.670 | 0.9512 | 2.1904 |

The shell and tube exchanger consists of four main parts:

The main steps in the calculation are given below:

Shell and Tube Heat Exchangers by two major types.

Design selection need to provide the following parameters:

The Heat Exchanger Tube Specifications Φ20 |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| DN | Quantity of tube pass | Quantity of heat exchanger tube | Quantity of center raw tube | tube pass flow area(m²) | Heat exchanger area(m²) | ||||

| Tube length(mm) | |||||||||

| 1500 | 2000 | 3000 | 4500 | 6000 | |||||

| 159 | 1 | 15 | 5 | 0.0030 | 1.4 | 1.9 | 2.8 | ||

| 219 | 1 | 33 | 7 | 0.0066 | 3.1 | 4.1 | 6.2 | ||

| 273 | 1 | 65 | 9 | 0.0131 | 6.1 | 8.2 | 12.3 | 18.4 | 24.5 |

| 2 | 56 | 8 | 0.0056 | 5.3 | 7.0 | 10.6 | 15.8 | 21.1 | |

| 325 | 1 | 99 | 11 | 0.0199 | 9.3 | 12.4 | 18.7 | 28.0 | 37.3 |

| 2 | 88 | 10 | 0.0088 | 8.3 | 11.1 | 16.6 | 24.9 | 33.2 | |

| 4 | 68 | 11 | 0.0034 | 6.4 | 8.5 | 12.8 | 19.2 | 25.6 | |

| 400 | 1 | 174 | 14 | 0.0350 | 16.4 | 21.9 | 32.8 | 49.2 | 65.8 |

| 2 | 164 | 15 | 0.0165 | 15.5 | 20.6 | 30.9 | 46.4 | 61.8 | |

| 4 | 146 | 14 | 0.0073 | 13.8 | 18.3 | 27.5 | 41.3 | 55.0 | |

| 450 | 1 | 237 | 17 | 0.0477 | 22.3 | 29.8 | 44.7 | 67.0 | 89.3 |

| 2 | 220 | 16 | 0.0221 | 20.7 | 27.8 | 41.5 | 62.2 | 82.9 | |

| 4 | 200 | 16 | 0.0101 | 18.8 | 25.1 | 37.7 | 56.5 | 75.4 | |

| 500 | 1 | 275 | 19 | 0.0553 | 34.6 | 51.8 | 77.8 | 103.7 | |

| 2 | 256 | 18 | 0.0257 | 32.2 | 48.3 | 72.4 | 96.5 | ||

| 4 | 222 | 18 | 0.0112 | 27.9 | 41.8 | 62.8 | 83.7 | ||

| The Heat Exchanger Tube Specifications Φ25 | |||||||||

| DN | Quantity of tube pass | Quantity of heat exchanger tube | Quantity of center raw tube | tube pass flow area(m²) | Heat exchanger area(m²) | ||||

| Tube length(mm) | |||||||||

| 1500 | 2000 | 3000 | 4500 | 6000 | |||||

| 159 | 1 | 11 | 3 | 0.0038 | 1.3 | 1.7 | 2.6 | ||

| 219 | 1 | 25 | 5 | 0.0087 | 2.9 | 3.9 | 5.6 | ||

| 273 | 1 | 38 | 6 | 0.0132 | 4.5 | 6.0 | 9.0 | 13.4 | 17.9 |

| 2 | 32 | 7 | 0.0055 | 3.8 | 5.0 | 7.5 | 11.3 | 15.1 | |

| 325 | 1 | 57 | 9 | 0.0197 | 6.7 | 9.0 | 13.4 | 20.1 | 26.9 |

| 2 | 56 | 9 | 0.0097 | 6.6 | 8.8 | 13.2 | 19.8 | 26.4 | |

| 4 | 40 | 9 | 0.0035 | 4.7 | 6.3 | 9.4 | 14.1 | 18.8 | |

| 400 | 1 | 98 | 12 | 0.0339 | 11.5 | 15.4 | 23.1 | 34.6 | 46.2 |

| 2 | 94 | 11 | 0.0163 | 11.1 | 14.8 | 22.1 | 33.2 | 44.3 | |

| 4 | 76 | 11 | 0.0066 | 9.0 | 11.9 | 17.9 | 26.9 | 35.8 | |

| 450 | 1 | 135 | 13 | 0.0468 | 15.9 | 21.2 | 31.8 | 47.7 | 63.6 |

| 2 | 126 | 12 | 0.0218 | 14.8 | 19.8 | 29.7 | 44.5 | 59.4 | |

| 4 | 106 | 13 | 0.0092 | 12.5 | 16.7 | 25.0 | 37.5 | 50.0 | |

| 500 | 1 | 174 | 14 | 0.0603 | 27.3 | 41.0 | 61.5 | 82.0 | |

| 2 | 164 | 15 | 0.0284 | 25.8 | 38.6 | 58.0 | 77.3 | ||

| 4 | 144 | 15 | 0.0125 | 22.6 | 33.9 | 50.9 | 67.9 | ||

| PRODUCTS | Manufacturing Capacity | Material Available |

|---|---|---|

| Bundle Assembly | 50 bundles/Month | Carbon Steel |

| Steel Structure | 30 Bays/Month | Low Alloy Carbon Steel |

| Finned Tube Exchangers | 200 tons/Month | Stainless Steel |

| Finning | High Alloy Steel | |

| Embedded “G” Type | 90,000 m/Month | Nickel Alloy |

| Footed “L” Type | 90,000m/Month | Titanium |

| Overlapped Footed “LL” type | 90,000m/Month | |

| Knurled “KL” Type | 90,000m/Month | |

| Extruded type | 100,000m/Month |

| OUTER DIAMETER (OD) | 0.500 - 3.000 inch 12.7 - 76.2 mm |

| WALL THICKNESS (WT) | 0.035 - 0.220 inch 0.89 - 5.52 mm |

Cold Drawn Heat Exchangers Tubes With Minimum Wall Thickness (Sizes In Inches)

| Outside | Minimum wall thickness | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| diameter | BWG (inch) | 20 (.035) | 18 (.049) | 16 (.065) | 14 (.083) | 13 (.095) | 12 (.109) | 11 (.120) | 10 (.134) | 9 (.148) | 8 (.165) | 7 (.180) | 6 (.203) | 5 (.220) | |

| [mm] | [inch] | [mm] |

0,89 | 1,24 | 1,65 | 2,11 | 2,41 | 2,77 | 3,05 | 3,40 | 3,76 | 4,19 | 4,57 | 5,16 | 5,59 |

| 1/2 | lb/ft | 0,190 | 0,256 | 0,327 | 0,399 | 0,441 | 0,487 | 0,519 | 0,555 | 0,586 | |||||

| 12,70 | .500 | kg/m | 0,283 | 0,381 | 0,487 | 0,594 | 0,657 | 0,725 | 0,773 | 0,826 | 0,873 | ||||

| 5/8 | lb/ft | 0,242 | 0,328 | 0,423 | 0,521 | 0,581 | 0,647 | 0,696 | 0,752 | 0,804 | |||||

| 15,88 | .625 | kg/m | 0,360 | 0,488 | 0,630 | 0,776 | 0,865 | 0,964 | 1,036 | 1,120 | 1,198 | ||||

| 3/4 | lb/ft | 0,400 | 0,518 | 0,643 | 0,720 | 0,807 | 0,872 | 0,948 | 1,021 | ||||||

| 19,05 | .750 | kg/m | 0,595 | 0,771 | 0,957 | 1,072 | 1,202 | 1,299 | 1,412 | 1,521 | |||||

| 7/8 | lb/ft | 0,472 | 0,614 | 0,767 | 0,864 | 0,973 | 1,056 | 1,158 | |||||||

| 22,23 | .875 | kg/m | 0,702 | 0,913 | 1,141 | 1,285 | 1,448 | 1,571 | 1,722 | ||||||

| 1 | lb/ft | 0,543 | 0,709 | 0,887 | 0,998 | 1,128 | 1,225 | 1,342 | 1,456 | 1,587 | 1,696 | ||||

| 25,40 | 1.000 | kg/m | 0,808 | 1,056 | 1,321 | 1,487 | 1,680 | 1,824 | 1,998 | 2,169 | 2,363 | 2,526 | |||

| 1 1/4 | lb/ft | 0,686 | 0,900 | 1,131 | 1,277 | 1,448 | 1,577 | 1,734 | 1,891 | 2,071 | 2,225 | 2,451 | 2,607 | ||

| 31,75 | 1.250 | kg/m | 1,022 | 1,340 | 1,684 | 1,902 | 2,157 | 2,349 | 2,583 | 2,816 | 3,085 | 3,313 | 3,650 | 3,882 | |

| 1 1/2 | lb/ft | 0,830 | 1,090 | 1,375 | 1,556 | 1,769 | 1,930 | 2,128 | 2,326 | 2,556 | 2,753 | 3,047 | 3,253 | ||

| 38,10 | 1.500 | kg/m | 1,236 | 1,624 | 2,048 | 2,317 | 2,634 | 2,875 | 3,169 | 3,464 | 3,807 | 4,100 | 4,538 | 4,845 | |

| 2 | lb/ft | 1,472 | 1,863 | 2,114 | 2,409 | 2,636 | 2,914 | 3,196 | 3,525 | 3,810 | 4,241 | 4,547 | |||

| 50,80 | 2.000 | kg/m | 2,192 | 2,775 | 3,148 | 3,588 | 3,925 | 4,340 | 4,759 | 5,250 | 5,674 | 6,316 | 6,771 | ||

| 2 1/2 | lb/ft | 1,854 | 2,351 | 2,671 | 3,050 | 3,341 | 3,701 | 4,066 | 4,494 | 4,867 | 5,435 | 5,839 | |||

| 63,50 | 2.500 | kg/m | 2,761 | 3,502 | 3,978 | 4,542 | 4,976 | 5,512 | 6,055 | 6,693 | 7,249 | 8,094 | 8,696 | ||

| 3 | lb/ft | 2,840 | 3,228 | 3,691 | 4,047 | 4,487 | 4,935 | 5,464 | 5,924 | 6,628 | 7,132 | ||||

| 76,20 | 3.000 | kg/m | 4,229 | 4,808 | 5,497 | 6,027 | 6,683 | 7,350 | 8,137 | 8,823 | 9,871 | 10,622 | |||

| Cold Drawn Heat Exchangers Tubes With Average Wall Thickness (Sizes In Inches) | |||||||||||||||

| Outside | Average wall thickness | ||||||||||||||

| diameter | BWG (inch) | 20 (.035) | 18 (.049) | 16 (.065) | 14 (.083) | 13 (.095) | 12 (.109) | 11 (.120) | 10 (.134) | 9 (.148) | 8 (.165) | 7 (.180) | 6 (.203) | 5 (.220) | |

| [mm] | [inch] | [mm] |

0,89 | 1,24 | 1,65 | 2,11 | 2,41 | 2,77 | 3,05 | 3,40 | 3,76 | 4,19 | 4,57 | 5,16 | 5,59 |

| 1/2 | lb/ft | 0.173 | 0.236 | 0.302 | 0.369 | 0.410 | 0.445 | 0.487 | 0.523 | 0.557 | |||||

| 12,70 | .500 | kg/m | 0,259 | 0,351 | 0,450 | 0,551 | 0,612 | 0,678 | 0,726 | 0,780 | 0,829 | ||||

| 5/8 | lb/ft | 0.220 | 0.301 | 0.388 | 0.480 | 0.537 | 0.600 | 0.647 | 0.703 | 0.754 | |||||

| 15,88 | .625 | kg/m | 0,328 | 0,447 | 0,579 | 0,716 | 0,801 | 0,897 | 0,965 | 1,046 | 1,124 | ||||

| 3/4 | lb/ft | 0.267 | 0.366 | 0.475 | 0.591 | 0.664 | 0.745 | 0.807 | 0.881 | 0.952 | |||||

| 19,05 | .750 | kg/m | 0,398 | 0,547 | 0,708 | 0,881 | 0,989 | 1,110 | 1,203 | 1,312 | 1,418 | ||||

| 7/8 | lb/ft | 0.432 | 0.562 | 0.702 | 0.791 | 0.891 | 0.967 | 1.060 | |||||||

| 22,23 | .875 | kg/m | 0,643 | 0,836 | 1,045 | 1,177 | 1,326 | 1,439 | 1,577 | ||||||

| 1 | lb/ft | 0.497 | 0.649 | 0.812 | 0.918 | 1.037 | 1.128 | 1.239 | 1.346 | 1.471 | 1.575 | ||||

| 25,40 | 1.000 | kg/m | 0,740 | 0,966 | 1,212 | 1,366 | 1,550 | 1,681 | 1,845 | 2,006 | 2,192 | 2,347 | |||

| 1 1/4 | lb/ft | 0.628 | 0.822 | 1.034 | 1.172 | 1.328 | 1.448 | 1.597 | 1.741 | 1.912 | 2.056 | 2.272 | 2.417 | ||

| 31,75 | 1.250 | kg/m | 0,933 | 1,225 | 1,542 | 1,744 | 1,980 | 2,159 | 2,377 | 2,595 | 2,848 | 3,063 | 3,383 | 3,606 | |

| 1 1/2 | lb/ft | 0.759 | 0.996 | 1.256 | 1.426 | 1.619 | 1.769 | 1.955 | 2.137 | 2.353 | 2.537 | 2.814 | 3.009 | ||

| 38,10 | 1.500 | kg/m | 1,127 | 1,483 | 1,870 | 2,121 | 2,413 | 2,636 | 2,909 | 3,184 | 3,504 | 3,779 | 4,191 | 4,481 | |

| 2 | lb/ft | 1.343 | 1.699 | 1.933 | 2.201 | 2.409 | 2.670 | 2.929 | 3.246 | 3.499 | 3.896 | 4.185 | |||

| 50,80 | 2.000 | kg/m | 2,000 | 2,533 | 2,876 | 3,281 | 3,591 | 3,974 | 4,362 | 4,816 | 5,210 | 5,807 | 6,232 | ||

| 2 1/2 | lb/ft | 1.690 | 2.143 | 2.440 | 2.783 | 3.050 | 3.385 | 3.717 | 4.126 | 4.460 | 4.980 | 5.360 | |||

| 63,50 | 2.500 | kg/m | 2,517 | 3,194 | 3,631 | 4,148 | 4,547 | 5,039 | 5,539 | 6,128 | 6,641 | 7,424 | 7,983 | ||

| 3 | lb/ft | 2.586 | 2.947 | 3.365 | 3.691 | 4.102 | 4.508 | 5.006 | 5.421 | 6.064 | 6.536 | ||||

| 76,20 | 3.000 | kg/m | 3,855 | 4,385 | 5,016 | 5,502 | 6,104 | 6,717 | 7,440 | 8,072 | 9,040 | 9,734 | |||

| SIZE | SINGLE BRAID | DOUBLE BRAID | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Static | Dynamic bend radius | Max. working | Test pressure | Burst | Static | Dynamic bend radius | Max. working | Test pressure | Burst | |

| bend radius | pressure | pressure | bend radius | pressure | pressure | ||||||

| Inch | mm | mm | mm | bar | bar | bar | mm | mm | bar | bar | bar |

| 1/4 | 6 | 25 | 100 | 154 | 230 | 616 | 25 | 100 | 246 | 369 | 984 |

| 3/8 | 10 | 40 | 150 | 105 | 157 | 420 | 40 | 150 | 168 | 252 | 672 |

| 1/2 | 12 | 50 | 200 | 88 | 132 | 352 | 50 | 200 | 140 | 210 | 560 |

| 5/8 | 16 | 50 | 200 | 73 | 109 | 292 | 50 | 200 | 116 | 174 | 464 |

| 3/4 | 20 | 70 | 200 | 64 | 96 | 256 | 70 | 200 | 102 | 153 | 408 |

| 1 | 25 | 90 | 200 | 50 | 75 | 200 | 90 | 200 | 80 | 120 | 320 |

| 1¼ | 32 | 110 | 250 | 42 | 63 | 168 | 110 | 250 | 67 | 100 | 268 |

| 1 ½ | 40 | 130 | 250 | 32 | 48 | 128 | 130 | 250 | 51 | 76 | 204 |

| 2 | 50 | 175 | 350 | 31 | 46 | 124 | 175 | 350 | 49 | 73 | 196 |

| 2 ½ | 65 | 200 | 410 | 26 | 39 | 104 | 200 | 410 | 41 | 61 | 164 |

| 3 | 80 | 205 | 450 | 18 | 27 | 72 | 205 | 450 | 28 | 42 | 112 |

| 4 | 100 | 230 | 560 | 16 | 24 | 64 | 230 | 560 | 26 | 39 | 104 |

| 5 | 125 | 280 | 660 | 16 | 24 | 64 | 280 | 660 | 25 | 37 | 100 |

| 6 | 150 | 320 | 815 | 12 | 18 | 48 | 320 | 815 | 20 | 30 | 80 |

| 8 | 200 | 435 | 1015 | 10 | 16 | 40 | 435 | 1015 | 16 | 24 | 64 |

| 10 | 250 | 560 | 1220 | 6.5 | 10 | 26 | 560 | 1220 | 10.5 | 16 | 42 |

| GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| NB SIZES | SCH 5 | SCH 10 | SCH 40 | SCH 80 | SCH 160 |

|---|---|---|---|---|---|

1/8″ |

√ |

√ |

√ |

√ |

|

1/4″ |

√ |

√ |

√ |

√ |

|

3/8″ |

√ |

√ |

√ |

√ |

|

1/2″ |

√ |

√ |

√ |

√ |

√ |

3/4″ |

√ |

√ |

√ |

√ |

√ |

1″ |

√ |

√ |

√ |

√ |

√ |

1 1/4″ |

√ |

√ |

√ |

√ |

√ |

1 1/2″ |

√ |

√ |

√ |

√ |

√ |

2″ |

√ |

√ |

√ |

√ |

√ |

2 1/2″ |

√ |

√ |

√ |

√ |

√ |

3″ |

√ |

√ |

√ |

√ |

√ |

4″ |

√ |

√ |

√ |

√ |

√ |

5″ |

√ |

√ |

√ |

√ |

|

6″ |

√ |

√ |

√ |

√ |