Due to the fact that either fittings or pipes made of this alloy are cleanable, stainless steel 316 tube has been classified as a hygienic or sanitary material. This 316 ss sanitary tubing system can be manually cleaned after it has been disassembled, or the cleaning can be done using a CIP, or clean in situ procedure. Utilizing ss 316 tubing as a sanitary material has the benefit of reducing entrapment regions, where germs could grow or hide. Additionally, these time-saving UNS S31600 tubes are quick and simple to clean..

But it's important to keep in mind that alloys chosen for sanitary tubes typically have high levels of corrosion resistance, such as SS 316 seamless tubing. Due to this alloy's resistant qualities, applications in the pharmaceutical and food and beverage sectors frequently achieve success when using alloy 316 tubes. As they serve clients from all over the world, these businesses have a very high need for sanitary materials like ASTM A554 tp316 tube.

They therefore need cleanliness and non-toxic final goods. The ASTM A270 tp316 tube is tested for mechanical qualities including tensile and yield strength, Rockwell hardness, and elongation since it is made in accordance with specific ASTM specifications.

Comapre price of 316 stainless steel tube with 304 stainless steel tube price list

| ASME and ASTM designation |

|

| Common Standards | ASTM, ASME and API |

| Thikness Available | thickness ranging from 0.1 to 1.2mm |

| Sizes range |

1/8" To 30″NB Inch OD: 0.35 to 6.35mm |

| ASME B36.10M Schedule Chart | SCH80, SCH20, SCH60, SCH80, SCH30, SCH140, SCH160, STD, SCH120, XS, XXS, SCH40, |

| Stock and Supply types | LSAW /Seamless/ Fabricated /ERW/Welded Tubes |

| Various Form | Hydraulic, Square, Rectangular, Round etc |

| Manufacturing Length | Cut Length, Double Random, Single Random etc |

| Tube End Abbreviations | Threaded, Plain End, Beveled End, |

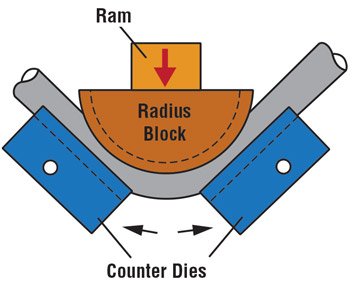

Tubing made of stainless steel 316 can be bent using a variety of techniques. Tubing can be bent with three-roll benders on the off chance that the bend has a wide range (additionally called section benders, profile benders, or angle rolls.) Tubing can be bent on a rotary-draw bender using a process known as mandrel tube bending if the curve has a narrow span.

Tubing made of stainless steel 316 can be bent using a variety of techniques. Tubing can be bent with three-roll benders on the off chance that the bend has a wide range (additionally called section benders, profile benders, or angle rolls.) Tubing can be bent on a rotary-draw bender using a process known as mandrel tube bending if the curve has a narrow span.

Bending is possible with both welded and seamless tubing. When the optimal range is constrained, seamless generally bends better.

Recently, we bent 6 pieces of 1.5 OD x 0.083 division (14 ga) 316 seamless stainless steel tubing to a 5.25 in inside sweep with 81 levels of bend and 6 in digressions on either end. These are prototypes for a vacuum get tube structure found in a food processing facility.

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Tubing 316ss 1/2 Odx.083 Wall 10ft Length Part No.tub-r-0145(Spare Parts For Hydralic Compressor)(960 Pcs) | 4,637 | 63.06 | 51.87 |

| 569.139.1y.tf.10.3 316l Ss Whirly 1 Tube Fe ( 20gpm/360) (Tank Cleaning Nozzle ( Machinery Spares ) | 20,347 | 276.71 | 227.61 |

| Seamless Ss Tubes Sandvik Grade 3r60 Tp316/l Acc To Astm A269 In Fixed 6mtrs-tht-3r60-10-1 Fl-167-6000(35kgs) | 316 | 4.30 | 3.53 |

| Seamless Ss Tubes Sandvik Grade 3r60 Tp316/l Acc To Astm A269 In-6 Mtr Length Tht-3r60-8-1 Fl-167-6000(169.00kgs) | 280 | 3.81 | 3.13 |

| Seamless Ss Tubes Sandvik Grade 3r60 Tp316/l Acc To Astm A269 In-6 Mtr Length Tht-3r60-10-1 Fl-167-6000 /197.00kgs | 316 | 4.30 | 3.53 |

| Seamless Ss Tubes Tp316/l Acc To Astm A269 In Fixed 6mtr Length-tht-3r60-6.35-1.24 Fl-250-6000(267.00kgs) | 387 | 5.26 | 4.33 |

| Seamless Ss Tubes Tp316/l Acc To Astm A269 In Fixed 6mtr Length-tht-3r60-6.35-1.24 Fl-250-6000(233.00kgs) | 300 | 4.08 | 3.36 |

| Ss Seamless Tubes Tht-3r60-12.7-1.65 - Sp. For Piping System(Qty=5 Pcs/14 Kgs) - (Ss316l Astm A269). | 992 | 13.49 | 11.10 |

| Ss Seamless Tubes Tht-3r60-6.35-0.89 - Sp. For Piping System(Qty=20 Pcs/15 Kgs) - (Ss316l Astm A269). | 439 | 5.97 | 4.91 |

| Ss Seamless Tubes Tht-3r60-12.7-0.89 - Sp. For Piping System(Qty=25 Pcs/41 Kgs) - (Ss316l Astm A269). | 778 | 10.58 | 8.70 |

| Ss Seamless Tube (Ss316l) Astm A269, Tht-3r60 [o/d-9.53mm, Thk-0.89mm, / 36 Kgs-30pcs] Compo (%): C-0.017 Cr-17.34 Ni-1 | 583 | 7.93 | 6.52 |

Indian manufacturers make ASTM a269 tubing that is both seamless and welded. It is a commercial grade of austenitic stainless steel that is employed in industries such as food processing, chemical manufacturing, dairy, etc. The sizes of drawn and welded tubes made of stainless steel type 316 range from 1/8" to a maximum of 24". Don't forget to ask your supplier for the mill test certificate A1016/A1016M.

Tube O.D. |

Nominal Wall Thickness, in. |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.010 |

0.012 |

0.014 |

0.016 |

0.020 |

0.028 |

0.035 |

0.049 |

0.065 |

0.083 |

0.095 |

0.109 |

0.120 |

0.134 |

0.156 |

0.188 |

|

Working Pressure, psig |

||||||||||||||||

1/16 |

5600 |

6800 |

8100 |

9400 |

12000 |

|

|

|

|

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

8500 |

10900 |

|

|

|

|

|

|

|

|

|

3/16 |

|

|

|

|

|

5400 |

7000 |

10200 |

|

|

|

|

|

|

|

|

1/4 |

|

|

|

|

|

4000 |

5100 |

7500 |

|

|

|

|

|

|

|

|

5/16 |

|

|

|

|

|

|

4000 |

5800 |

8000 |

|

|

|

|

|

|

|

3/8 |

|

|

|

|

|

|

3300 |

4800 |

6500 |

|

|

|

|

|

|

|

1/2 |

|

|

|

|

|

|

2600 |

3700 |

5100 |

6700 |

|

|

|

|

|

|

5/8 |

|

|

|

|

|

|

|

2900 |

4000 |

5200 |

6000 |

|

|

|

|

|

3/4 |

|

|

|

|

|

|

|

2400 |

3300 |

4200 |

4900 |

5800 |

|

|

|

|

7/8 |

|

|

|

|

|

|

|

2000 |

2800 |

3600 |

4200 |

4800 |

|

|

|

|

1 |

|

|

|

|

|

|

|

|

2400 |

3100 |

3600 |

4200 |

4700 |

|

|

|

1 1/4 |

|

|

|

|

|

|

|

|

|

2400 |

2800 |

3300 |

3600 |

4100 |

4900 |

|

1 1/2 |

|

|

|

|

|

|

|

|

|

|

2300 |

2700 |

3000 |

3400 |

4000 |

4900 |

| Stainless Steel Tube Size and Weight | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness in mm | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.6 | 3 | 3.2 | 3.6 |

| O. D. in mm Weight in kg/m | ||||||||||||

| 6 | 0.069 | 0.081 | 0.093 | 0.104 | 0.125 | 0.144 | 0.176 | – | – | – | – | – |

| 10 | 0.119 | 0.141 | 0.163 | 0.184 | 0.225 | 0.264 | 0.336 | – | – | – | – | – |

| 12.7 | 0.153 | 0.182 | 0.21 | 0.238 | 0.293 | 0.345 | 0.444 | – | – | – | – | – |

| 14 | 0.169 | 0.201 | 0.233 | 0.264 | 0.325 | 0.384 | 0.496 | – | – | – | – | – |

| 15.87 | 0.192 | 0.229 | 0.266 | 0.301 | 0.372 | 0.44 | 0.571 | 0.694 | – | – | – | – |

| 19 | 0.231 | 0.276 | 0.32 | 0.364 | 0.45 | 0.534 | 0.696 | 0.85 | 1.066 | 1.2 | 1.264 | – |

| 25 | 0.306 | 0.366 | 0.425 | 0.484 | 0.6 | 0.714 | 0.936 | 1.15 | 1.456 | 1.65 | 1.744 | 1.926 |

| 25.4 | 0.311 | 0.372 | 0.432 | 0.492 | 0.61 | 0.726 | 0.952 | 1.17 | 1.482 | 1.68 | 1.776 | 1.962 |

| 31.8 | – | – | – | – | – | 0.918 | 1.208 | 1.49 | 1.898 | 2.16 | 2.288 | 2.538 |

| 38 | – | – | – | – | – | 1.104 | 1.456 | 1.8 | 2.301 | 2.625 | 2.784 | 3.096 |

| 44.5 | – | – | – | – | – | 1.299 | 1.716 | 2.125 | 2.724 | 3.113 | 3.304 | 3.681 |

| 50.8 | – | – | – | – | – | – | 1.968 | 2.44 | 3.133 | 3.585 | 3.808 | 4.248 |

| 63.5 | – | – | – | – | – | – | 2.476 | 3.075 | 3.959 | 4.538 | 4.824 | 5.391 |

| 76.1 | – | – | – | – | – | – | 2.98 | 3.705 | 4.778 | 5.483 | 5.832 | 6.525 |

| 101.6 | – | – | – | – | – | – | 4 | 4.98 | 6.435 | 7.395 | 7.872 | 8.82 |

| 114.3 | – | – | – | – | – | – | 4.453 | 5.547 | 7.173 | 8.247 | 8.78 | 9.84 |

| 127 | – | – | – | – | – | – | 4.955 | 6.175 | 7.989 | 9.188 | 9.785 | 10.98 |

| 152.4 | – | – | – | – | – | – | 5.96 | 7.429 | 9.62 | 11.07 | 11.792 | 13.231 |

Weight=(OD-WT)*WT*0.02513=Kg/Meter

OD: Outer Diameter

WT: Wall thickness

| Vickers | Brinell | Rockwell | Shore |

|---|---|---|---|

| HV | HB | HRC | C |

| 200 | 200 | - | 28 |

| 210 | 210 | - | 29 |

| 220 | 220 | - | 30 |

| 230 | 230 | 19.2 | 31 |

| 240 | 240 | 21.2 | 33 |

| 250 | 250 | 23.0 | 34 |

| 260 | 260 | 24.7 | 35 |

| 270 | 270 | 26.1 | 36 |

| 280 | 280 | 27.6 | 37 |

| 290 | 290 | 29.0 | 39 |

| 300 | 300 | 30.3 | 40 |

| 310 | 310 | 31.5 | 41 |

| 320 | 320 | 32.9 | 42 |

| 330 | 330 | 33.8 | 43 |

| 340 | 340 | 34.9 | 44 |

| 350 | 350 | 36.0 | 45 |

| 360 | 359 | 37.0 | 46 |

| 370 | 368 | 38.0 | 47 |

| 380 | 373 | 38.9 | 48 |

| 390 | 385 | 39.8 | 49 |

| 400 | 393 | 40.7 | 50 |

| 410 | 400 | 41.5 | 51 |

| 420 | 407 | 42.3 | 52 |

| 430 | 416 | 43.2 | 53 |

| 440 | 423 | 44.0 | 54 |

| 450 | 429 | 44.8 | 55 |

| 460 | 435 | 45.5 | 56 |

| 470 | 441 | 46.3 | 57 |

| 480 | 450 | 47.0 | 58 |

| 490 | 457 | 47.7 | 59 |

| 500 | 465 | 48.3 | 60 |

| 510 | 474 | 49.0 | 61 |

| 520 | 482 | 49.6 | 62 |

| 530 | 489 | 50.3 | 63 |

| 540 | 496 | 50.9 | 64 |

| 550 | 503 | 51.5 | 65 |

| 560 | 511 | 52.1 | 66 |

| 570 | 520 | 52.7 | 67 |

| 580 | 527 | 53.3 | 68 |

| 590 | 533 | 53.8 | 69 |

| 600 | 538 | 54.4 | 70 |

| 610 | 543 | 54.9 | 71 |

| 620 | 549 | 55.4 | 72 |

| 630 | 555 | 55.9 | 73 |

| 640 | 561 | 56.4 | 74 |

| 650 | 568 | 56.9 | 75 |

| 660 | 574 | 57.4 | 75 |

| 670 | 581 | 57.9 | 76 |

| 680 | 588 | 58.4 | 77 |

| 690 | 595 | 58.9 | 78 |

| 700 | 602 | 59.3 | 79 |

| 710 | 609 | 59.8 | 80 |

| 720 | 616 | 60.2 | 81 |

| 730 | 622 | 60.7 | 82 |

| 740 | 627 | 61.1 | 83 |

| 750 | 633 | 61.5 | 83 |

| 760 | 639 | 61.9 | 84 |

| 770 | 644 | 62.3 | 85 |

| 780 | 650 | 62.7 | 86 |

| 790 | 656 | 63.1 | 86 |

| 800 | 661 | 63.5 | 87 |

| 810 | 666 | 63.9 | 87 |

| 820 | 670 | 64.3 | 88 |

| 830 | 677 | 64.6 | 89 |

| 840 | 682 | 65.0 | 89 |

| 850 | - | 65.3 | 90 |

| 860 | - | 65.7 | 90 |

| 870 | - | 66.0 | 91 |

| 880 | - | 66.3 | 91 |

| 890 | - | 66.6 | 92 |

| 900 | - | 66.9 | 92 |

| GAUGE | THICKNESS RANGE (INCH) | TYPICAL VALUE (INCH) |

|---|---|---|

| 22 | 0.025 - 0.029 | 0.028 |

| 20 | 0.031 - 0.035 | 0.035 |

| 19 | 0.038 - 0.042 | 0.042 |

| 18 | 0.044 - 0.049 | 0.049 |

| 17 | 0.053 - 0.058 | 0.058 |

| 16 | 0.060 - 0.065 | 0.065 |

| 15 | 0.066 - 0.074 | 0.072 |

| 14 | 0.075 - 0.085 | 0.083 |

| 13 | 0.087 - 0.097 | 0.095 |

| 12 | 0.101 - 0.111 | 0.109 |

| 11 | 0.112 - 0.122 | 0.12 |

| 10 | 0.126 - 0.136 | 0.134 |

| 9 | 0.140 - 0.150 | 0.148 |

| 8 | 0.157 - 0.167 | 0.165 |

| 7 | 0.175 - 0.185 | 0.18 |

Stainless Steel 316 Tube

Size: 1/8" To 30″NB Inch

OD: 0.35 to 6.35mm

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | min. | – | – | – | – | – | 16.0 | 2.0 | 10.0 | – |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.0 | 14.0 | 0.10 | |

| Grade | Elongation (% in 50mm) min | Strength of Yield 0.2% Proof (MPa) minimum | Strength of Tensile (MPa) minimum | Pipe Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) maximum | Brinell (HB) maximum | ||||

| 316 | 40 | 205 | 515 | 95 | 217 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | Name | ||||

| 316 | S31600 | 304S11 | 58E | 1.4401 | X5CrNiMo17-12-2 | 2347 | SUS 316 |

Comparatively speaking, the SA213 specification of tubes can have thicker walls than the A269 specification. Compared to the a269 tubes, the sa213 tubes have a range of up to 12.7mm. High temperatures and pressures are present during nuclear power plant operation. The capacity to contain pressure will increase as wall thickness increases. The a269 tubes are welded and less exact in terms of measurements than the sa213 tubes, which are seamless. The a269 pipes can withstand higher pressure and heat than the tubes made to sa213 requirements, despite their less precise welding and manufacture. Therefore, the a269 tubes are more suitable for use in nuclear power plants.

| Square Tubing- | Nominal Size | Wall Thickness | Weight per Ft. |

|---|---|---|---|

| 1 1/2x1 1/2-3.35# | 1 1/2 x 1 1/2 in | 0.1875 in | 3.35 lb |

| 1 1/2x1 1/2-3.71# | 1 1/2 x 1 1/2 in | 0.2500 in | 3.71 lb |

| 2x2-4.32# | 2 x 2 in | 0.1875 in | 4.32 lb |

| 2x2-5.41# | 2 x 2 in | 0.2500 in | 5.41 lb |

| 2 1/2x2 1/2-5.59# | 2 1/2 x 2 1/2 in | 0.1875 in | 5.59 lb |

| 2 1/2x2 1/2-7.11# | 2 1/2 x 2 1/2 in | 0.2500 in | 7.11 lb |

| 2 1/2x2 1/2-8.94# | 2 1/2 x 2 1/2 in | 0.3125 in | 8.94 lb |

| 3x3-6.87# | 3 x 3 in | 0.1875 in | 6.87 lb |

| 3x3-8.81# | 3 x 3 in | 0.2500 in | 8.81 lb |

| 3x3-10.58# | 3 x 3 in | 0.3125 in | 10.58 lb |

| 3x3-12.51# | 3 x 3 in | 0.3750 in | 12.51 lb |

| 3 1/2x3 1/2-8.15# | 3 1/2 x 3 1/2 in | 0.1875 in | 8.15 lb |

| 3 1/2x3 1/2-10.51# | 3 1/2 x 3 1/2 in | 0.2500 in | 10.51 lb |

| 3 1/2x3 1/2-12.70# | 3 1/2 x 3 1/2 in | 0.3125 in | 12.70 lb |

| 3 1/2x3 1/2-15.46# | 3 1/2 x 3 1/2 in | 0.3750 in | 15.46 lb |

| 4x4-9.42# | 4 x 4 in | 0.1875 in | 9.42 lb |

| 4x4-12.21# | 4 x 4 in | 0.2500 in | 12.21 lb |

| 4x4-14.83# | 4 x 4 in | 0.3125 in | 14.83 lb |

| 4x4-17.27# | 4 x 4 in | 0.3750 in | 17.27 lb |

| 4x4-21.63# | 4 x 4 in | 0.5000 in | 21.63 lb |

| 4 1/2x4 1/2-10.70# | 4 1/2 x 4 1/2 in | 0.1875 in | 10.70 lb |

| 4 1/2x4 1/2-13.91# | 4 1/2 x 4 1/2 in | 0.2500 in | 13.91 lb |

| 5x5-11.97# | 5 x 5 in | 0.1875 in | 11.97 lb |

| 5x5-15.62# | 5 x 5 in | 0.2500 in | 15.62 lb |

| 5x5-19.08# | 5 x 5 in | 0.3125 in | 19.08 lb |

Size OD, Inches |

BW Ga. |

Wall Dec-In. |

ID |

Weight Lbs/Ft. |

|---|---|---|---|---|

1/8 |

22 |

0.028 |

0.069 |

0.0290 |

20 |

0.035 |

0.055 |

0.0336 |

|

3/16 |

22 |

0.028 |

0.131 |

0.0478 |

1/4

|

25 |

0.020 |

0.210 |

0.0491 |

22 |

0.028 |

0.194 |

0.0664 |

|

21 |

0.032 |

0.187 |

0.0745 |

|

20 |

0.035 |

0.180 |

0.0804 |

|

18 |

0.049 |

0.152 |

0.1052 |

|

16 |

0.065 |

0.120 |

0.1284 |

|

5/16

|

20 |

0.035 |

0.242 |

0.1039 |

18 |

0.049 |

0.214 |

0.1382 |

|

16 |

0.065 |

0.182 |

0.1722 |

|

3/8

|

22 |

0.028 |

0.319 |

0.1038 |

20 |

0.035 |

0.305 |

0.1271 |

|

18 |

0.049 |

0.277 |

0.1706 |

|

16 |

0.065 |

0.245 |

0.2152 |

|

7/16 |

18 |

0.049 |

0.340 |

0.2036 |

1/2

|

25 |

0.020 |

0.460 |

0.1025 |

20 |

0.035 |

0.430 |

0.1738 |

|

18 |

0.049 |

0.402 |

0.2360 |

|

16 |

0.065 |

0.370 |

0.3020 |

|

5/8

|

20 |

0.035 |

0.555 |

0.2205 |

18 |

0.049 |

0.527 |

0.3014 |

|

16 |

0.065 |

0.495 |

0.3888 |

|

3/4

|

20 |

0.035 |

0.680 |

0.2673 |

18 |

0.049 |

0.652 |

0.3668 |

|

16 |

0.065 |

0.620 |

0.4755 |

|

14 |

0.083 |

0.584 |

0.5913 |

|

7/8

|

18 |

0.049 |

0.777 |

0.4323 |

16 |

0.065 |

0.745 |

0.5623 |

|

11 |

0.120 |

0.635 |

0.9676 |

|

1

|

20 |

0.035 |

0.930 |

0.3607 |

18 |

0.049 |

0.902 |

0.4977 |

|

16 |

0.065 |

0.870 |

0.6491 |

|

14 |

0.083 |

0.834 |

0.8129 |

|

11 |

0.120 |

0.760 |

1.1278 |

|

1-1/4 |

11 |

0.120 |

1.010 |

1.4480 |

| Temperature Rating | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (inches) |

Pipe Schedule | Outside Diameter (in) |

Wall Thickness (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

|

Tube Specifications

|

|

|

| OD inches | Ave. Wall inches | Min Yield Strength (PSI) | Min Tensile Strength (PSI) | Theoretical Burst Pressure * (PSI) | Working Pressure (PSI) 25% of Burst | Theoretical Yield Point ** (PSI) | Collapse Pressure *** (PSI) |

|---|---|---|---|---|---|---|---|

| 0.250 | 0.020 | 30,000 | 75,000 | 14,286 | 3,571 | 5,714 | 4,416 |

| 0.250 | 0.028 | 30,000 | 75,000 | 21,649 | 5,412 | 8,660 | 5,967 |

| 0.250 | 0.035 | 30,000 | 75,000 | 29,167 | 7,292 | 11,667 | 7,224 |

| 0.250 | 0.049 | 30,000 | 75,000 | 48,355 | 12,089 | 19,342 | 9,455 |

| 0.250 | 0.065 | 30,000 | 75,000 | 81,250 | 20,313 | 32,500 | 11,544 |

| 0.375 | 0.020 | 30,000 | 75,000 | 8,955 | 2,239 | 3,582 | 3,029 |

| 0.375 | 0.028 | 30,000 | 75,000 | 13,166 | 3,292 | 5,266 | 4,145 |

| 0.375 | 0.035 | 30,000 | 75,000 | 17,213 | 4,303 | 6,885 | 5,077 |

| 0.375 | 0.049 | 30,000 | 75,000 | 26,534 | 6,634 | 10,614 | 6,816 |

| 0.375 | 0.065 | 30,000 | 75,000 | 39,796 | 9,949 | 15,918 | 8,597 |

| 0.500 | 0.020 | 30,000 | 75,000 | 6,522 | 1,630 | 2,609 | 2,201 |

| 0.500 | 0.028 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.500 | 0.035 | 30,000 | 75,000 | 12,209 | 3,052 | 4,884 | 3,906 |

| 0.500 | 0.049 | 30,000 | 75,000 | 18,284 | 4,571 | 7,313 | 5,201 |

| 0.500 | 0.065 | 30,000 | 75,000 | 26,351 | 6,588 | 10,541 | 6,786 |

| 0.500 | 0.083 | 30,000 | 75,000 | 37,275 | 9,319 | 14,910 | 8,307 |

| 0.625 | 0.020 | 30,000 | 75,000 | 5,128 | 1,282 | 2,051 | 1,859 |

| 0.625 | 0.028 | 30,000 | 75,000 | 7,381 | 1,845 | 2,953 | 2,568 |

| 0.625 | 0.035 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.625 | 0.049 | 30,000 | 75,000 | 13,947 | 3,487 | 5,579 | 4,335 |

| 0.625 | 0.065 | 30,000 | 75,000 | 19,697 | 4,924 | 7,879 | 5,591 |

| 0.625 | 0.083 | 30,000 | 75,000 | 27,124 | 6,781 | 10,850 | 6,910 |

| 0.625 | 0.095 | 30,000 | 75,000 | 32,759 | 8,190 | 13,103 | 7,734 |

| 0.625 | 0.109 | 30,000 | 75,000 | 40,172 | 10,043 | 16,069 | 8,639 |

| 0.750 | 0.028 | 30,000 | 75,000 | 6,052 | 1,513 | 2,421 | 2,156 |

| 0.750 | 0.035 | 30,000 | 75,000 | 7,721 | 1,930 | 3,088 | 2,669 |

| 0.750 | 0.049 | 30,000 | 75,000 | 11,273 | 2,818 | 4,509 | 3,664 |

| 0.750 | 0.065 | 30,000 | 75,000 | 15,726 | 3,931 | 6,290 | 4,749 |

| 0.750 | 0.083 | 30,000 | 75,000 | 21,318 | 5,330 | 8,527 | 5,905 |

| 0.750 | 0.095 | 30,000 | 75,000 | 25,446 | 6,362 | 10,179 | 6,637 |

| 0.750 | 0.109 | 30,000 | 75,000 | 30,733 | 7,683 | 12,293 | 7,453 |

| 0.750 | 0.120 | 30,000 | 75,000 | 35,294 | 8,824 | 14,118 | 8,064 |

| 0.875 | 0.020 | 30,000 | 75,000 | 3,593 | 898 | 1,437 | 1,340 |

| 0.875 | 0.028 | 30,000 | 75,000 | 5,128 | 1,282 | 2,051 | 1,859 |

| 0.875 | 0.035 | 30,000 | 75,000 | 6,522 | 1,630 | 2,609 | 2,201 |

| 0.875 | 0.049 | 30,000 | 75,000 | 9,459 | 2,365 | 3,784 | 3,172 |

| 0.875 | 0.065 | 30,000 | 75,000 | 13,087 | 3,272 | 5,235 | 4,126 |

| 0.875 | 0.083 | 30,000 | 75,000 | 17,560 | 4,390 | 7,024 | 5,152 |

| 0.875 | 0.095 | 30,000 | 75,000 | 20,803 | 5,201 | 8,321 | 5,807 |

| 0.875 | 0.109 | 30,000 | 75,000 | 24,886 | 6,221 | 9,954 | 6,543 |

| 0.875 | 0.120 | 30,000 | 75,000 | 28,346 | 7,087 | 11,339 | 7,100 |

| 1.000 | 0.028 | 30,000 | 75,000 | 4,449 | 1,112 | 1,780 | 1,633 |

| 1.000 | 0.035 | 30,000 | 75,000 | 5,645 | 1,411 | 2,258 | 2,027 |

| 1.000 | 0.049 | 30,000 | 75,000 | 8,149 | 2,037 | 3,259 | 2,796 |

| 1.000 | 0.065 | 30,000 | 75,000 | 11,207 | 2,802 | 4,483 | 3,647 |

| 1.000 | 0.083 | 30,000 | 75,000 | 14,928 | 3,732 | 5,971 | 4,567 |

| 1.000 | 0.095 | 30,000 | 75,000 | 17,593 | 4,398 | 7,037 | 5,159 |

| 1.000 | 0.109 | 30,000 | 75,000 | 20,908 | 5,227 | 8,363 | 5,827 |

| 1.000 | 0.120 | 30,000 | 75,000 | 23,684 | 5,921 | 9,474 | 6,336 |

| 1.000 | 0.134 | 30,000 | 75,000 | 27,459 | 6,865 | 10,984 | 6,963 |

| 1.250 | 0.035 | 30,000 | 75,000 | 4,449 | 1,112 | 1,780 | 1,633 |

| 1.250 | 0.049 | 30,000 | 75,000 | 6,380 | 1,595 | 2,552 | 2,260 |

| 1.250 | 0.065 | 30,000 | 75,000 | 8,705 | 2,176 | 3,482 | 2,958 |

| 1.250 | 0.083 | 30,000 | 75,000 | 11,485 | 2,871 | 4,594 | 3,719 |

| 1.250 | 0.095 | 30,000 | 75,000 | 13,443 | 3,361 | 5,377 | 4,213 |

| 1.250 | 0.109 | 30,000 | 75,000 | 15,843 | 3,961 | 6,337 | 4,776 |

| 1.250 | 0.120 | 30,000 | 75,000 | 17,822 | 4,455 | 7,129 | 5,207 |

| 1.250 | 0.134 | 30,000 | 75,000 | 20,468 | 5,117 | 8,187 | 5,742 |

| 1.500 | 0.035 | 30,000 | 75,000 | 3,671 | 918 | 1,469 | 1,367 |

| 1.500 | 0.049 | 30,000 | 75,000 | 5,243 | 1,311 | 2,097 | 1,896 |

| 1.500 | 0.065 | 30,000 | 75,000 | 7,117 | 1,779 | 2,847 | 2,487 |

| 1.500 | 0.083 | 30,000 | 75,000 | 9,333 | 2,333 | 3,733 | 3,136 |

| 1.500 | 0.095 | 30,000 | 75,000 | 10,878 | 2,719 | 4,351 | 3,559 |

| 1.500 | 0.109 | 30,000 | 75,000 | 12,754 | 3,188 | 5,101 | 4,043 |

| 1.500 | 0.120 | 30,000 | 75,000 | 14,286 | 3,571 | 5,714 | 4,416 |

| 1.500 | 0.134 | 30,000 | 75,000 | 16,315 | 4,079 | 6,526 | 4,881 |

| 1.500 | 0.148 | 30,000 | 75,000 | 18,439 | 4,610 | 7,375 | 5,336 |

| 1.750 | 0.035 | 30,000 | 75,000 | 3,125 | 781 | 1,250 | 1,176 |

| 1.750 | 0.049 | 30,000 | 75,000 | 3,864 | 966 | 1,546 | 1,434 |

| 1.750 | 0.065 | 30,000 | 75,000 | 6,019 | 1,505 | 2,407 | 2,146 |

| 1.750 | 0.083 | 30,000 | 75,000 | 7,860 | 1,965 | 3,144 | 2,711 |

| 1.750 | 0.095 | 30,000 | 75,000 | 9,135 | 2,284 | 3,654 | 3,080 |

| 1.750 | 0.109 | 30,000 | 75,000 | 10,672 | 2,668 | 4,213 | 3,504 |

| 1.750 | 0.120 | 30,000 | 75,000 | 11,921 | 2,980 | 4,768 | 3,832 |

| 1.750 | 0.134 | 30,000 | 75,000 | 13,563 | 3,391 | 5,425 | 4,242 |

| 1.750 | 0.148 | 30,000 | 75,000 | 15,268 | 3,817 | 6,107 | 4,645 |

| 1.750 | 0.165 | 30,000 | 75,000 | 17,430 | 4,357 | 6,972 | 5,124 |

| 2.000 | 0.035 | 30,000 | 75,000 | 2,720 | 680 | 1,088 | 1,032 |

| 2.000 | 0.049 | 30,000 | 75,000 | 3,864 | 966 | 1,546 | 1,434 |

| 2.000 | 0.065 | 30,000 | 75,000 | 5,214 | 1,303 | 2,086 | 1,887 |

| 2.000 | 0.083 | 30,000 | 75,000 | 6,788 | 1,697 | 2,715 | 2,387 |

| 2.000 | 0.095 | 30,000 | 75,000 | 7,873 | 1,968 | 3,149 | 2,715 |

| 2.000 | 0.109 | 30,000 | 75,000 | 9,175 | 2,294 | 3,670 | 3,092 |

| 2.000 | 0.120 | 30,000 | 75,000 | 10,227 | 2,557 | 4,091 | 3,384 |

| 2.000 | 0.134 | 30,000 | 75,000 | 11,605 | 2,901 | 4,642 | 3,751 |

| 2.000 | 0.148 | 30,000 | 75,000 | 13,028 | 3,257 | 5,211 | 4,111 |

| 2.000 | 0.165 | 30,000 | 75,000 | 14,820 | 3,705 | 5,928 | 4,542 |

DIAMETER TOLERANCE 316 STAINLESS STEEL TUBE

| NPS | Stainless Steel 304 Tube OD Tolerance | |||

|---|---|---|---|---|

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 |

1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) |

0.4 0.8 1.6 2.4 3.2 4.0 4.8 |

1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) |

0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

WALL THICKNESS TOLERANCE STAINLESS STEEL 316 TUBES

| NPS | Stainless Steel 304 / 304L Tube Tolerance, % | |

|---|---|---|

| + | – | |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

| Size by Inch (diameter) | Thickness |

Sizes by MM (diameter) |

Thickness |

|---|---|---|---|

inch |

inch |

mm | mm |

1“ x 1/2" |

0.065" |

10mm×15mm |

0.6mm~1.5mm |

| 1“ x 3/4" |

0.065" |

10mm×20mm |

0.6mm~1.5mm |

| 0.095" | 14mm×21mm |

0.6mm~1.5mm |

|

| 1 1/4" x 3/4" |

0.065" |

15mm×30mm |

0.6mm~1.5mm |

| 1 1/2" x 3/4" |

0.065" |

15mm×38mm |

0.6mm~1.5mm |

| 0.120" | 20mm×20mm |

0.6mm~2mm |

|

1 1/2" x 1" |

0.065" |

20mm×30mm |

0.6mm~2mm |

0.072" |

20mm×40mm |

0.6mm~2mm |

|

0.083" |

20mm×50mm |

0.6mm~2mm |

|

0.120" |

22mm×35mm |

0.6mm~2mm |

|

2“ x 1” |

0.065" |

25mm×40mm |

0.9mm~2mm |

0.083" |

25mm×65mm |

0.9mm~3.75mm |

|

0.120" |

30mm×20mm |

1mm~2mm |

|

0.188" |

30mm×40mm |

1mm~3.75mm |

|

2” x 1 1/4“ |

0.065" |

30mm×45mm |

1mm~3.75mm |

0.083" |

30mm×50mm |

1mm~3.75mm |

|

2“ x 1 1/2” |

0.083" |

30mm×60mm |

1mm~4mm |

0.120" |

40mm×25mm |

1mm~4.5mm |

|

| 2 1/2“ x 1 1/2” |

0.072" |

40mm×50mm |

1mm~4.5mm |

0.083" |

40mm×60mm |

1mm~4.5mm |

|

0.120" |

40mm×80mm |

1mm~5mm |

|

0.148" |

40mm×100mm |

1mm~5mm |

|

0.188" |

50mm×25mm |

2mm~5mm |

|

0.250" |

50mm×30mm |

2mm~5mm |

|

| 3" x 1" | 0.083" |

50mm×60mm |

2mm~5mm |

0.120" |

50mm×80mm |

2mm~5mm |

|

0.188" |

50mm×100mm |

2mm~5mm |

|

| 3“ x 1 1/2” |

0.083" |

60mm×30mm |

2mm~6mm |

0.120" |

60mm×40mm |

2mm~6mm |

|

0.188" |

60mm×80mm |

2mm~6mm |

|

| 0.250" | 70mm×50mm |

2mm~6mm |

|

3“ x 2” |

0.065 |

80mm×30mm |

2mm~8mm |

0.083 |

80mm×40mm |

2mm~8mm |

|

0.125 |

80mm×60mm |

2mm~8mm |

|

0.188 |

80mm×100mm |

2mm~8mm |

|

0.250 |

100mm×50mm |

2mm~8mm |

|

3“ x 2” |

0.083" |

120mm×60mm |

2.5mm~10mm |

0.120" |

120mm×80mm |

2.5mm~10mm |

|

0.188" |

140mm×60mm |

2.5mm~10mm |

|

0.250" |

140mm×80mm |

2.5mm~10mm |

|

| 0.312" | 150mm×100mm |

2.5mm~12mm |

|

4“ x 1 1/2” |

0.120" |

160mm×80mm |

2.5mm~12mm |

0.188" |

180mm×150mm |

2.5mm~12mm |

|

| 4“ x 2” |

0.083" |

200mm×100mm |

4mm~12mm |

0.120" |

200mm×150mm |

4mm~12mm |

|

0.188" |

220mm×140mm |

4mm~12mm |

|

0.250" |

250mm×150mm |

6mm~12mm |

|

0.312" |

250mm×100mm |

6mm~12mm |

|

0.375" |

250mm×200mm |

6mm~30mm |

|

4“ x 2 1/2” |

0.188" |

300mm×100mm |

6mm~30mm |

0.250" |

300mm×150mm |

6mm~30mm |

|

| 4" x 3" | 0.083" |

300mm×200mm |

6mm~30mm |

0.120" |

300mm×250mm |

6mm~30mm |

|

0.188" |

400mm×250mm |

8mm~30mm |

|

0.250" |

400mm×300mm |

8mm~30mm |

|

0.312" |

450mm×200mm |

8mm~30mm |

|

0.375" |

450mm×250mm |

8mm~30mm |

|

| 4 1/2“ x 2 1/2” |

0.188" |

400mm×300mm |

8mm~30mm |

0.250" |

400mm×350mm |

8mm~30mm |

|

| 5" x 2” | 0.120" |

500mm×200mm |

10mm~30mm |

0.188" |

500mm×250mm |

10mm~30mm |

|

0.250" |

500mm×300mm |

10mm~30mm |

|

0.312" |

500mm×350mm |

10mm~30mm |

|

0.375" |

500mm×400mm |

10mm~30mm |

|

| 5" x 2 1/2” |

0.120" |

500mm×450mm |

10mm~30mm |

0.188" |

600mm×200mm |

10mm~28mm |

|

0.250" |

600mm×400mm |

10mm~28mm |

|

| 5" x 3" |

0.188" |

600mm×500mm |

10mm~28mm |

0.250" |

800mm×400mm |

10mm~28mm |

|

0.312" |

800mm×600mm |

10mm~28mm |

|

0.375" |

800mm×700mm |

10mm~28mm |

|

0.500" |

1000mm×400mm |

10mm~28mm |

|

5" x 4" |

0.188" |

1000mm×500mm |

10mm~28mm |

0.250" |

1000mm×600mm |

10mm~28mm |

|

0.312" |

1000mm×800mm |

10mm~28mm |

|

0.375" |

|||

6" x 2" |

0.120" |

||

0.188" |

|||

0.250" |

|||

0.312" |

|||

0.375" |

| O.D. | Wall Thickness | Nominal I.D. | Weight |

|---|---|---|---|

| 1/8 inches3.175 mm | 0.035 inches0.8890 mm | 0.055 inches1.397 mm | 0.0337 lbs/ft0.0501511268 kg/m |

| 3/16 inches4.7625 mm | 0.035 inches0.8890 mm | 0.118 inches2.9972 mm | 0.0570 lbs/ft0.084825348 kg/m |

| 1/4 inches6.35 mm | 0.028 inches0.7112 mm | 0.194 inches4.9276 mm | 0.0664 lbs/ft0.0988140896 kg/m |

| 1/4 inches6.35 mm | 0.035 inches0.8890 mm | 0.180 inches4.572 mm | 0.0804 lbs/ft0.1196483856 kg/m |

| 1/4 inches6.35 mm | 0.049 inches1.2446 mm | 0.152 inches3.8608 mm | 0.1052 lbs/ft0.1565548528 kg/m |

| 1/4 inches6.35 mm | 0.065 inches1.6510 mm | 0.120 inches3.048 mm | 0.1285 lbs/ft0.191229074 kg/m |

| 3/8 inches9.525 mm | 0.035 inches0.8890 mm | 0.505 inches12.827 mm | 0.1271 lbs/ft0.1891456444 kg/m |

| 3/8 inches9.525 mm | 0.049 inches1.2446 mm | 0.277 inches7.0358 mm | 0.1707 lbs/ft0.2540295948 kg/m |

| 3/8 inches9.525 mm | 0.065 inches1.6510 mm | 0.245 inches6.223 mm | 0.2153 lbs/ft0.3204017092 kg/m |

| 1/2 inches12.70 mm | 0.035 inches0.8890 mm | 0.430 inches10.922 mm | 0.1739 lbs/ft0.2587917196 kg/m |

| 1/2 inches12.70 mm | 0.049 inches1.2446 mm | 0.402 inches10.2108 mm | 0.2361 lbs/ft0.3513555204 kg/m |

| 1/2 inches12.70 mm | 0.065 inches1.6510 mm | 0.370 inches9.398 mm | 0.3021 lbs/ft0.4495743444 kg/m |

| 1/2 inches12.70 mm | 0.12 inches3.0480 mm | 0.260 inches6.604 mm | 0.4872 lbs/ft0.7250335008 kg/m |

| 5/8 inches15.875 mm | 0.035 inches0.8890 mm | 0.555 inches14.097 mm | 0.2206 lbs/ft0.3282889784 kg/m |

| 5/8 inches15.875 mm | 0.049 inches1.2446 mm | 0.527 inches13.3858 mm | 0.3015 lbs/ft0.448681446 kg/m |

| 5/8 inches15.875 mm | 0.065 inches1.6510 mm | 0.495 inches12.573 mm | 0.3889 lbs/ft0.5787469796 kg/m |

| 3/4 inches19.05 mm | 0.035 inches0.8890 mm | 0.680 inches17.272 mm | 0.2674 lbs/ft0.3979350536 kg/m |

| 3/4 inches19.05 mm | 0.049 inches1.2446 mm | 0.652 inches16.5608 mm | 0.3670 lbs/ft0.546156188 kg/m |

| 3/4 inches19.05 mm | 0.065 inches1.6510 mm | 0.620 inches15.748 mm | 0.4757 lbs/ft0.7079196148 kg/m |

| 7/8 inches22.225 mm | 0.083 inches2.1082 mm | 0.709 inches18.0086 mm | 0.7023 lbs/ft1.0451375772 kg/m |

| 1 inches25.40 mm | 0.065 inches1.6510 mm | 0.870 inches22.098 mm | 0.6493 lbs/ft0.9662648852 kg/m |

| 1 inches25.40 mm | 0.12 inches3048 mm | 0.760 inches19.304 mm | 1.282 lbs/ft1.907826248 kg/m |

Product Name |

OD |

WT |

Finish |

|---|---|---|---|

Square Pipe/Tube |

8*8mm to 300*300mm |

0.3mm-30mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Round Pipe/Tube |

6mm-630mm |

0.3mm-30mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Rectangular Pipe/Tube |

10*20mm~100*200mm |

0.3mm-30mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Single Slot Pipe/Tube |

38.1-76.2mm |

1.0mm-2.0mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Wood Colour Pipe/Tube |

Can be customised |

Can be customised |

– |

Signal Slot Oval Pipe/Tube |

Size:40-110mm |

1.0mm-2.0mm; |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Double Slot Round Pipe/Tube |

38.1-76.2mm |

1.0mm-2.0mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Double Slot Square Pipe/Tube |

Slot Width and Length:10mm -30mm |

1.0mm-2.0mm; |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Signal Slot Rectangular Pipe/Tube |

Slot Width and Height:10mm- 30mm |

1.0mm-2.0mm; |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Triangle Tube |

Side Length: 16mm - 85mm |

0.5mm-3.0mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Oval Tube |

Sizes:4mm (short distance) ~ 270mm (Long Distance) |

1.0mm -3.0mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

316 Stainless Steel Handrail Tube |

– |

1.0-1.8 |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Hexagonal Tube |

Side Length: 13mm - 85mm |

0.5mm-1.8mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Flat Oval Tube |

2.3*10.3—63*175 |

1.0—1.8 |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Arched Shaped Tube |

15*22—35*75 |

1.0—1.8 |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Fan Shaped Tube |

11*10*R15—80*80*R50 |

1.0—1.8 |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

316 Inner polished Stainless steel tube |

Size:12.5mm - 203.2mm |

1.0mm - 5mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Heat Exchange Tube-A249 |

Seamless Tube: 12.7~76.2 x 0.5~6.35mm Welding Tube: 12.7~76.2 x 0.5~3.175mm

|

|

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

316 thin-wall Stainless steel tube-A270 |

22mm-108mm |

0.7-2.0 |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

316 Stainless steel tube for the general equipment–A269 |

WD:0.5mm-30mm |

OD:10mm-300mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

316 Stainless steel seamless tube |

Size: 6mm - 430mm |

0.8mm - 30mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |

Capillary tube |

OD:0.28mm -10mm |

0.08mm - 1.2mm |

2B,400#Bright, Brushed (180#,220#,240#,320#400#,600#), Hairline, 8K Mirror, etc |