Because of their propensity to have extremely high ductility, stainless steel is favoured. Any oval stainless steel tubing's ductility depends on its microstructure, which is a product of the metal's alloying composition. Consider an alloy grade like 316 Stainless Steel Oval Tube as an example. The metal's microstructure contains an austenite crystal. Nickel is a component of austenite's alloy, which contributes to its formation and stability.

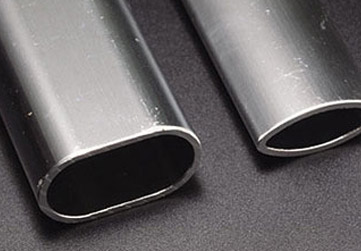

Austenite has a face centre cubic microstructure, also known as an FCC, which makes the alloy of Flat Oval Stainless Steel Tube ductile due to the tightly packed atoms. Due to their ductility, austenitic stainless steels may be formed into a variety of shapes, from simple square, rectangular, and round shapes to more intricate ones like the Flat Sided Oval Stainless Steel Tube. In addition to being produced in a variety of shapes, stainless steel oval tubes can have variable diameters, wall thicknesses, and circumferences.

The use of an oval tube has a number of advantages for users. For instance, stainless steel elliptical oval tubes have a stronger construction and, despite being ductile, are more difficult to distort. Additionally, because to its extremely compact design, the majority of Oval Stainless Steel Tube Suppliers advise using these tubes in applications where there are issues with available space or where compact components are required.

| Size | 1/2" NB to 24" NB |

| Standards | ASTM A312 |

| Form | Oval Pipes |

| Tolerance on length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| Finish | Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm, Polished Grit 120 – 600, Mirror Polished |

| Oval Tube Sizes | |

|---|---|

| 11 x 19 | 0.9mm – 1.5mm |

| 12 x 23 | 0.9mm – 1.5mm |

| 13 x 33 | 0.9mm – 1.5mm |

| 15 x 33 | 0.9mm – 1.5mm |

| 19 x 45 | 0.9mm – 1.5mm |

| 25 x 65 | 0.9mm – 1.5mm |

Grade of Material |

C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| AISI 201 | ≤0.15 | ≤1.00 | 5.50~7.50 | ≤0.060 | ≤0.03 | 1.00 ~1.50 | 13.50~15.00 | \ |

| AISI 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~11.00 | 18.00~20.00 | \ |

| AISI 316L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

Grade of Material |

Elongation (%) | Tensile Strength (Rm) N/m m³ | Yield Strength (Rp) 0.2%N/m m³ | Hardness (HV) | ||||

|---|---|---|---|---|---|---|---|---|

| AISI 201 | ≥35 | ≥515 | ≥205 | ≤200 | ||||

| AISI 304 | ≥35 | ≥515 | ≥205 | ≤200 | ||||

| AISI 316L | ≥35 | ≥485 | ≥170 | ≤200 | ||||