Superalloys, also referred to as inconel alloys, are a type of metals with chromium and nickel in their fundamental chemical makeup. The Inconel tig rod is very resistant to oxidation because of this base chemistry. Therefore, any Indian maker of inconel round bars would advise using these alloys for situations where there is a lot of moisture in the air. The inconel x750 round bar/rod is suitable for applications where the alloy is subjected to pressure and heat in harsh conditions in addition to being resistant to oxidation corrosion.

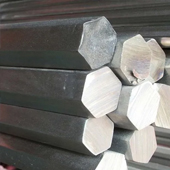

The aerospace sector is one use for this alloy that the inconel round bar providers suggest. The Inconel square bar may be employed in areas like jet engines because the applications carried out in this field include high temperatures that are at an intense level. The inconel hex bar has the capacity to develop a protective oxide layer when exposed to high heat. The Inconel Round Bar's resistance to heat is a result of the protective layer that coats the alloy's surface. The inconel welding rod not only resists oxidation and works well in high pressure and high temperatures, but it also demonstrates superior resistance to various types of corrosion across various media. At elevated temperature ranges, the inconel flat bar demonstrates excellent tensile strength in comparison to conventional stainless steel alloys.

before buy compare price of Inconel Round bar with Monel round bar price list

| Dimensions | BS, DIN, EN, AISI, JIS, ASME, ASTM |

|---|---|

| size of Round bar | Thickness: 2 milimeter-100 milimeter |

| size of Flat bar | Width: 10 milimeter - 500 milimeter |

| Dia: 3 milimeter-~800 milimeter | |

| Channel Bars | 80 x 40 milimeter- 150 x 75 milimeter section; 5.0 - 6.0 milimeter thickness |

| size of Angle bar | 3*20*20 milimeter~12*100*100 milimeter |

| Size of Billet | 1/2 - 495 milimeter Diameter |

| Rectangular Bars Section | 3.0 - 12.0 milimeter thickness |

| Form | Round, Rod, T-Bars, Channel Bars, Precision Ground Bars, Flat Bars, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Threaded, Hex (A/F), Rectangle, Half Round Bars, Profiles, Billet, Ingot, Forging, I/H Bars etc. |

| Size of Rectangles | 33 x 30 milimeter - 295 x 1066 milimeter |

| Surface | Bright, Hot Rolled Pickled, Hairline, Cold Drawn, Sand Blasting Finished, Polished |

| Processing | cutting to 650 milimeter |

| Hollow Bars sizes | 32mm Outside diameter x 16 milimeter Inside diameter to 250 milimeter Outside diameter x 200 milimeter Inside diameter) |

| Tolerance | H9, K9, H8, H12, K12, H11, H13, K10, K11, H10, or as per need |

| Finish | centreless ground, Cold (bright) drawn, smooth turned, hot rolled, slit rolled edge, peeled, Rough Turned, hot rolled annealed, Polish, Bright, Centreless Ground, Grinding & Black |

| Method | Cold Drawn, Hot Rolled, Cold Rolled Rod, Forged Round Bars |

| Condition | annealed, Hardened & tempered |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Nickel Alloy Bars - Inconel 600 Dia 40 Mm(1 Pcs) | 4,296 | 58.17 | 48.01 |

| Rm-0-07-001-0002 Rd Bars Inconel Alloy 625 Dia 1.75 (44.45mm (02 Bars) | 2,927 | 39.63 | 32.71 |

| Rm-0-07-001-0001 Rd Bars Inconel Alloy 625 Dia 1.25 (31.75mm) (01 Bars) | 2,956 | 40.03 | 33.04 |

| Stainless Steel Bars Inconel 718 Ams 5662 50mm Dia | 3,480 | 47.12 | 38.89 |

| Inconel Bar (7 Pcs) | 4,526 | 61.29 | 50.58 |

| (F.o.c. Item) Inconel Bar (3 Pcs) | 4,673 | 63.28 | 52.23 |

| Inconel Bar (14 Pcs) | 5,420 | 73.39 | 60.58 |

| Inconel Alloy 693 Round Bar Annealed Asme Sb166 Uns N06693 | 138,578 | 1876.44 | 1548.81 |

| Bright drawn | BD | Slit rolled edge | SRE |

| Cold drawn | CD | Polished | P |

| Peeled and turned | P&T | Rough turned/peeled | RT |

| Cold finished | CF | Hot rolled annealed and pickled | HRAP |

| Centreless ground | CG | Hot finished | HF |

| Smooth turned | ST | Peeled and reeled | PR |

| Section/Shape | diameter, Size or width across flats | variation Permitted |

|---|---|---|

| millimeter | millimeter | |

| Flat (thickness) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 |

+ 0 to - 00.110 + 0 to - 00.130 + 0 to - 00.250 + 0 to - 00.350 |

| Square and hexagon |

≥ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 105 |

+ 0 to - 00.090 + 0 to - 00.110 + 0 to - 00.130 + 0 to - 00.160 + 0 to - 00.250 |

| Round | ≥6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 |

+ 0 to - 00.070 + 0 to - 00.085 + 0 to - 00.100 + 0 to - 00.120 + 0 to - 00.140 |

| Flat (width) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 > 100 ≦ 130 > 130 ≦ 160 > 160 ≦ 320 |

+ 0 to - 00.110 + 0 to - 00.130 + 0 to - 00.160 + 0 to - 00.190 + 0 to - 00.220 + 0 to - 00.350 + 0 to - 1.00 + 1.00 to - 1.00 |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

|---|---|---|---|---|---|---|---|

| Diam. (Inch) | Bar Size | Diam. (mm) | Bar Size | Diameter (mm) | Bar Size | Diameter (mm2) | Bar Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot | Size | kilogram / Meter | kilogram / Foot |

|---|---|---|---|---|---|---|---|---|

| 1/8" | 0.062 | 0.019 | 22mm | 2.979 | 0.908 | 3-1/4" | 41.996 | 12.800 |

| 3mm | 0.055 | 0.017 | 20mm | 2.470 | 0.753 | 3" | 35.762 | 10.900 |

| 4mm | 0.098 | 0.030 | 24mm | 3.543 | 1.080 | 3-3/4" | 55.780 | 17.001 |

| 5/32" | 0.095 | 0.029 | 7/8" | 3.038 | 0.926 | 3-1/2" | 48.772 | 14.850 |

| 5mm | 0.154 | 0.047 | 1" | 3.970 | 1.210 | 4-1/4" | 72.249 | 21.908 |

| 3/16" | 0.141 | 0.043 | 25mm | 3.871 | 1.180 | 4" | 63.340 | 19.306 |

| 6mm | 0.223 | 0.068 | 27mm | 4.490 | 1.368 | 4-3/4" | 90.249 | 27.366 |

| 7/32" | 0.190 | 0.058 | 26mm | 4.170 | 1.271 | 4-1/2" | 80.340 | 24.4487 |

| 7mm | 0.298 | 0.091 | 30mm | 5.548 | 1.691 | 5-1/2" | 121.000 | 36.690 |

| 1/4" | 0.249 | 0.076 | 1-1/8" | 5.033 | 1.534 | 5" | 99.940 | 30.461 |

| 8mm | 0.398 | 0.120 | 32mm | 6.314 | 1.894 | 6-1/2" | 167.630 | 51.093 |

| 5/16" | 0.387 | 0.118 | 1-1/4" | 6.349 | 1.924 | 6" | 143.900 | 43.860 |

| 3/8" | 0.557 | 0.170 | 35mm | 7.553 | 2.390 | 7-1/2" | 225.000 | 68.226 |

| 9mm | 0.498 | 0.152 | 1-3/8" | 7.550 | 2.303 | 7" | 196.000 | 59.432 |

| 11mm | 0.748 | 0.228 | 38mm | 8.903 | 2.792 | 10" | 397.140 | 121.048 |

| 10mm | 0.620 | 0.189 | 36mm | 7.999 | 2.438 | 8" | 254.55 | 77.586 |

| 12mm | 0.889 | 0.271 | 40mm | 9.872 | 3.009 | |||

| 7/16" | 0.761 | 0.232 | 1-1/2" | 8.951 | 2.715 | |||

| 13mm | 1.043 | 0.318 | 1-3/4" | 12.179 | 3.712 | |||

| 1/2" | 0.994 | 0.303 | 1-5/8" | 10.449 | 3.200 | |||

| 9/16" | 1.256 | 0.383 | 1-7/8" | 13.977 | 4.260 | |||

| 14mm | 1.207 | 0.368 | 45mm | 12.555 | 3.807 | |||

| 5/8" | 1.551 | 0.473 | 50mm | 15.414 | 4.698 | |||

| 15mm | 1.391 | 0.424 | 48mm | 14.205 | 4.330 | |||

| 17mm | 1.791 | 0.543 | 2-1/8" | 17.963 | 5.475 | |||

| 16mm | 1.578 | 0.481 | 2" | 15.906 | 4.848 | |||

| 18mm | 2.001 | 0.610 | 60mm | 22.205 | 6.768 | |||

| 11/16" | 1.880 | 0.573 | 2-1/4" | 20.128 | 6.135 | |||

| 3/4" | 2.237 | 0.682 | 2-3/8" | 22.435 | 6.838 | |||

| 2-1/2" | 24.856 | 7.576 | ||||||

| 2-5/8" | 27.409 | 8.354 | ||||||

| 2-3/4" | 30.083 | 9.169 |

International Spec.: |

DIN 17742, WERKSTOFF Nr 2.4816, BS 3072-3076 (NA14), DIN 17754, DIN 17750, AFNOR-NC 15 Fe, TÜV 305 |

Specifications: |

AMS 5665, ASTM B166, |

|

|

hex bar Size in Inches |

hex bar Wt per Ft |

hex bar Wt per 12′ |

|---|---|---|

3/16″ |

0.104 |

1.248 |

1/4″ |

0.180 |

2.160 |

5/16″ |

0.290 |

3.480 |

3/8″ |

0.625 |

4.920 |

7/16″ |

0.560 |

6.72 |

1/2″ |

0.740 |

8.880 |

9/16″ |

0.930 |

11.16 |

5/8″ |

1.150 |

13.80 |

11/16″ |

1.390 |

16.68 |

3/4″ |

1.660 |

19.92 |

13/16″ |

1.950 |

23.40 |

7/8″ |

2.300 |

27.60 |

15/16″ |

2.625 |

31.20 |

1″ |

2.90 |

34.80 |

1-1/16″ |

3.30 |

39.60 |

1-1/8″ |

3.700 |

44.40 |

1-1/4″ |

4.625 |

55.20 |

1-5/16″ |

5.100 |

61.20 |

1-3/8″ |

5.625 |

67.20 |

1-7/16″ |

6.100 |

73.20 |

1-1/2″ |

6.625 |

79.20 |

1-5/8″ |

7.800 |

93.60 |

1-3/4″ |

9.030 |

108.36 |

1-7/8″ |

10.400 |

124.80 |

2″ |

11.80 |

141.60 |

2-1/4″ |

14.920 |

179.04 |

2-3/8″ |

16.920 |

203.04 |

2-1/2″ |

18.42 |

221.04 |

3″ |

26.53 |

318.36 |

H&T |

Hardened and tempered. |

ANN |

Annealed |

PH |

Precipitation hardened. |

Inconel Flat bar – metric sizes and weights |

|||

|---|---|---|---|

Flat Size |

KG’s per Metre |

Standard Length (metres) |

Colour Code |

10 x 3 |

0.24 |

6.0 |

Blue |

13 x 3 |

0.31 |

6.0 |

Blue |

13 x 5 |

0.46 |

6.0 |

Orange |

16 x 3 |

0.38 |

6.0 |

Blue |

16 x 5 |

0.64 |

6.0 |

Orange |

16 x 8 |

1.03 |

6.0 |

Red |

20 x 3 |

0.48 |

6.0 |

Blue |

20 x 5 |

0.81 |

6.0 |

Orange |

20 x 6 |

0.97 |

6.0 |

White |

20 x 10 |

1.61 |

6.0 |

Yellow |

25 x 3 |

0.60 |

6.0 |

Blue |

25 x 5 |

1.01 |

6.0 |

Orange |

25 x 6 |

1.21 |

6.0 |

White |

25 x 8 |

1.61 |

6.0 |

Red |

25 x 10 |

2.01 |

6.0 |

Yellow |

25 x 12 |

2.41 |

6.0 |

Pink |

32 x 3 |

0.77 |

6.0 |

Blue |

32 x 5 |

1.29 |

6.0 |

Orange |

32 x 6 |

1.55 |

6.0 |

White |

32 x 8 |

2.06 |

6.0 |

Red |

32 x 10 |

2.58 |

6.0 |

Yellow |

32 x 12 |

3.09 |

6.0 |

Pink |

40 x 3 |

0.97 |

6.0 |

Blue |

40 x 5 |

1.61 |

6.0 |

Orange |

40 x 6 |

1.93 |

6.0 |

White |

40 x 8 |

2.58 |

6.0 |

Red |

40 x 10 |

3.22 |

6.0 |

Yellow |

40 x 12 |

3.86 |

6.0 |

Pink |

40 x 16 |

5.15 |

6.0 |

Grey |

40 x 20 |

6.14 |

6.0 |

Green |

50 x 3 |

1.21 |

6.0 |

Blue |

50 x 5 |

2.01 |

6.0 |

Orange |

50 x 6 |

2.41 |

6.0 |

White |

50 x 8 |

3.22 |

6.0 |

Red |

50 x 10 |

4.02 |

6.0 |

Yellow |

50 x 12 |

4.83 |

6.0 |

Pink |

50 x 16 |

6.44 |

6.0 |

Grey |

50 x 20 |

8.05 |

6.0 |

Green |

50 x 25 |

10.1 |

6.0 |

Purple |

65 x 3 |

1.57 |

6.0 |

Blue |

65 x 5 |

2.62 |

6.0 |

Orange |

65 x 6 |

3.14 |

6.0 |

White |

65 x 8 |

4.18 |

6.0 |

Red |

65 x 10 |

5.23 |

6.0 |

Yellow |

65 x 12 |

6.28 |

6.0 |

Pink |

65 x 16 |

8.37 |

6.0 |

Grey |

65 x 20 |

10.5 |

6.0 |

Green |

65 x 25 |

13.1 |

6.0 |

Purple |

75 x 5 |

3.02 |

6.0 |

Orange |

75 x 6 |

3.62 |

6.0 |

White |

75 x 8 |

4.83 |

6.0 |

Red |

75 x 10 |

6.04 |

6.0 |

Yellow |

75 x 12 |

7.24 |

6.0 |

Pink |

75 x 16 |

9.66 |

6.0 |

Grey |

75 x 20 |

12.1 |

6.0 |

Green |

75 x 25 |

15.1 |

6.0 |

Purple |

75 x 40 |

24.1 |

6.0 |

Yellow |

90 x 5 |

3.62 |

6.0 |

Orange |

90 x 6 |

4.35 |

6.0 |

White |

90 x 8 |

5.79 |

6.0 |

Red |

90 x 10 |

7.24 |

6.0 |

Yellow |

90 x 12 |

8.69 |

6.0 |

Pink |

100 x 5 |

4.02 |

6.0 |

Orange |

100 x 6 |

4.83 |

6.0 |

White |

100 x 8 |

6.44 |

6.0 |

Red |

100 x 10 |

8.05 |

6.0 |

Yellow |

100 x 12 |

9.66 |

6.0 |

Pink |

100 x 16 |

12.9 |

6.0 |

Grey |

100 x 20 |

16.1 |

6.0 |

Green |

100 x 25 |

20.1 |

6.0 |

Purple |

100 x 50 |

40.2 |

6.0 |

Green |

110 x 6 |

5.31 |

6.0 |

White |

110 x 8 |

7.08 |

6.0 |

Red |

110 x 10 |

8.85 |

6.0 |

Yellow |

110 x 12 |

10.6 |

6.0 |

Pink |

130 x 5 |

5.23 |

6.0 |

Orange |

130 x 6 |

6.28 |

6.0 |

White |

130 x 8 |

8.37 |

6.0 |

Red |

130 x 10 |

10.5 |

6.0 |

Yellow |

130 x 12 |

12.6 |

6.0 |

Pink |

130 x 16 |

16.7 |

6.0 |

Grey |

130 x 20 |

20.9 |

6.0 |

Green |

130 x 25 |

26.2 |

6.0 |

Purple |

150 x 5 |

6.04 |

6.0 |

Orange |

150 x 6 |

7.24 |

6.0 |

White |

150 x 8 |

9.66 |

6.0 |

Red |

150 x 10 |

12.1 |

6.0 |

Yellow |

150 x 12 |

14.5 |

6.0 |

Pink |

150 x 16 |

19.3 |

6.0 |

Grey |

150 x 20 |

24.1 |

6.0 |

Green |

150 x 25 |

30.1 |

6.0 |

Purple |

150 x 50 |

60.4 |

6.0 |

Green |

180 x 5 |

7.24 |

6.0 |

Orange |

180 x 6 |

8.69 |

6.0 |

White |

180 x 10 |

14.5 |

6.0 |

Yellow |

180 x 12 |

17.4 |

6.0 |

Pink |

180 x 16 |

23.2 |

6.0 |

Grey |

180 x 20 |

29.0 |

6.0 |

Green |

180 x 25 |

36.2 |

6.0 |

Purple |

200 x 6 |

9.66 |

6.0 |

White |

200 x 8 |

12.9 |

6.0 |

Red |

200 x 10 |

16.1 |

6.0 |

Yellow |

200 x 12 |

19.3 |

6.0 |

Pink |

200 x 16 |

25.7 |

6.0 |

Grey |

200 x 20 |

32.2 |

6.0 |

Green |

200 x 25 |

40.3 |

6.0 |

Purple |

250 x 6 |

12.1 |

6.0 |

White |

250 x 8 |

16.1 |

6.0 |

Red |

250 x 10 |

20.1 |

6.0 |

Yellow |

250 x 12 |

24.1 |

6.0 |

Pink |

250 x 16 |

32.2 |

6.0 |

Grey |

250 x 20 |

40.2 |

6.0 |

Green |

250 x 25 |

50.3 |

6.0 |

Purple |

300 x 6 |

14.5 |

6.0 |

White |

300 x 8 |

19.3 |

6.0 |

Red |

300 x 10 |

24.1 |

6.0 |

Yellow |

300 x 12 |

29.0 |

6.0 |

Pink |

300 x 16 |

38.6 |

6.0 |

Grey |

300 x 20 |

48.3 |

6.0 |

Green |

300 x 25 |

60.4 |

6.0 |

Purple |

| Size & Dimensions of inconel round bar | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

|

|

0.2% Proof Stress |

Tensile Strength |

Elongation |

Reduction of area |

Hardness |

|---|---|---|---|---|

MPA |

MPA |

% |

% |

HRC |

Min |

Min |

Min |

Min |

Min |

827 |

1034 |

17 |

25 |

40 |

| Type | SIZES (mm) | SIZES (Inches) | ISO Tolerance |

|---|---|---|---|

| Cold Drawn and Polish | 3.00 – 75.00 | 1/8” – 3.00” | h8-h9-h10-h11, ASTM B637 |

| Cold Drawn and Ground | 10.00 – 75.00 | 5/6” – 2.50” | h8-h9-h10-h11 |

| Peeled and Polished | 40.00 – 150.00 | 1.50” – 6.00” | h11, ASTMA-484 h11-DIN 1013 |

| Peeled and Ground | 20.00 – 50.00 | 3/4″ – 2.00” | h9-h10-h11, ASTM B160 |

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | AFNOR | ||||

| Inconel 600 Pipe | N06600 | NA 13 | NiCr15Fe | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | NCF 600 |

| Inconel 625 | N06625 | NA 21 | NiCr22Mo9Nb | 2.4856 | NC22DNB4M | ХН75МБТЮ | NCF 625 |

| Inconel 601 | N06601 | NA 49 | NiCr23Fe | 2.4851 | NC23FeA | XH60BT | NCF 601 |

| Incoloy 825 | N08825 | NA 16 | NiCr21Mo | 2.4858 | NFE30C20DUM | ЭП703 | NCF 825 |

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | |||

| Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 | – | – |

| Inconel | Element (% By Mass) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Fe | Mo | Nb | Co | Mn | Cu | Al | Ti | Si | C | S | P | B | |

| 600 | 72.0 | 14.0–17.0 | 6.0–10.0 | 1.0 | 0.5 | 0.5 | 0.15 | 0.015 | |||||||

| 617 | 44.2–56.0 | 20.0–24.0 | 3.0 | 8.0–10.0 | 10.0–15.0 | 0.5 | 0.5 | 0.8–1.5 | 0.6 | 0.5 | 0.15 | 0.015 | 0.015 | 0.006 | |

| 625 | 58.0 | 20.0–23.0 | 5.0 | 8.0–10.0 | 3.15–4.15 | 1.0 | 0.5 | 0.4 | 0.4 | 0.5 | 0.1 | 0.015 | 0.015 | ||

| 690 | 59.5 | 30 | 9.2 | 0.35 | 0.01 | 0.02 | 0.35 | 0.019 | 0.003 | ||||||

| 718 | 50.0–55.0 | 17.0–21.0 | Balance | 2.8–3.3 | 4.75–5.5 | 1.0 | 0.35 | 0.2–0.8 | 0.65–1.15 | 0.3 | 0.35 | 0.08 | 0.015 | 0.015 | 0.006 |

| X-750 | 70.0 | 14.0–17.0 | 5.0–9.0 | 0.7–1.2 | 1.0 | 1.0 | 0.5 | 0.4–1.0 | 2.25–2.75 | 0.5 | 0.08 | 0.01 | |||