Fasteners manufactured in accordance with ASTM F467 specifications are nonferrous alloys. Because of its name, nonferrousastm f467 uns n06625 nuts neither contain iron nor have a significant enough amount of iron in their chemical makeup to qualify as ferrous containing alloys. Consequently, any commercially available non-ferrous alloy may be used to create the ASTM F467 Grade 5 Nuts.

Most specifications, including this one, cover various requirements of the ASME SF467 Dome Nuts. The specifications' requirements correspond to the mechanical properties of the product in addition to its chemical composition. ASTM F467 Nyloc Nuts. Moreover, other requirements covered by the specification include its dimensions, workmanship, finishes used as well as the test methods for the ASTM F467 Metric Nuts. After testing the various components the ASTM F467 Coupling Nuts, are required to conform to certain criteria for e.g. its hardness, tensile stress areas, and proof stress.

The use of ASTM F467 Square Nuts is frequently linked to industries that need fasteners for several purposes. Therefore, it is typical to see sectors like the oil refinery, pulp and paper industry, acid processing plants, gas scrubbing, and salt water equipment utilising the ASTM F467 Hex Nuts.

compare Astm F467 Uns N06625 Nuts price with Stainlesss Steel 316 Nuts price list

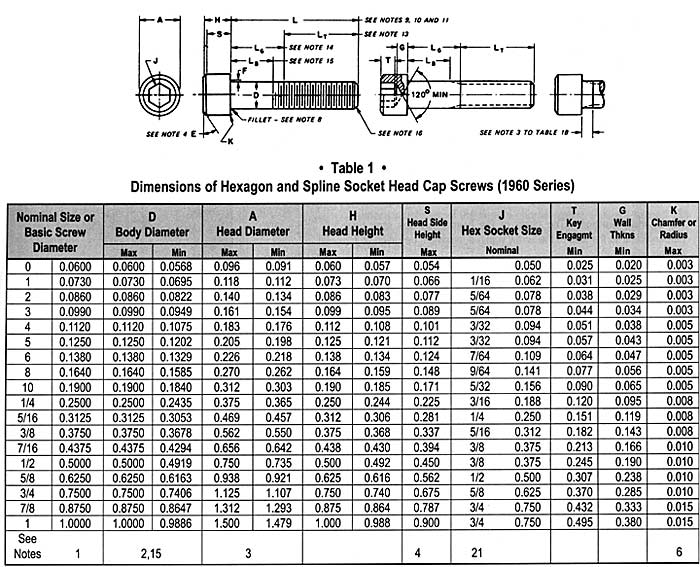

Dimensions |

ASME B18.2.1, B18.3 |

|---|---|

Melt Origin |

South America/East Europe/JapanKorea/ |

Product Origin |

Made in India |

Threads Configuration |

ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

Certification |

Dual Certified As per ASTM & ASME Codes |

Additional Certifications |

PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

Mandatory Requirements |

Free from Mercury & Radioactive Contamination |

Additional Requirements |

NACE MR0103 / MR0175 / ISO 15156 Compliance |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Hex Bolt Ft 1/2 - 13unc X 60mm B18.2.1- Inconel 625 Other Screws And Bolts W/nwith Their Nuts Or Washers Threaded | 401 | 5.45 | 4.48 |

| Heavy Hex Nut 1/2 - 13unc B18.2.2 - Inconel 625 Threaded Nuts | 147 | 2.00 | 1.64 |

| Hex Bolt Ft 1/2 - 13unc X 60mm B18.2.1- Inconel 625 Other Screws And Bolts W/nwith Their Nuts Or Washers Threaded | 321 | 4.36 | 3.58 |

| Hex Bolt Ft 1/2 - 13unc X 60mm B18.2.1- Inconel 625 Other Screws And Bolts W/nwith Their Nuts Or Washers Threaded | 401 | 5.45 | 4.48 |

| Inconel625 Stud : Nut & Washer For Stud:size : 5/8 | 372 | 5.06 | 4.15 |

| Inconel625 Stud : Nut & Washer For Stud: Size 1/2 | 288 | 3.91 | 3.22 |

| Inconel625 Stud : Nut & Washer For Stud:size : 3/4 | 865 | 11.76 | 9.66 |

| Supply Of Industrial Items:- 7/16 Od X3/8 Npt Male Through Bore Connector With Nut & Sleeve Inconel 625 Wp 5000psi | 3,303 | 44.90 | 36.89 |

| Inconel 625 Bolt+nut+washer (Size:3/8 X1-1/2) | 1,864 | 25.34 | 20.82 |

| Hex Nut M3 - 0.5p Din 934 - Inconel 625 | 430 | 5.85 | 4.80 |

| Nuts/bolts/screws/washer Made Of Alloysteel Including Stainless Steel-din 934, Inconel 625, Hex Nut M12 | 167 | 2.27 | 1.87 |

| Nominal Size, inch. | Coarse Threads - UNC | Fine Threads - UNF | 8 Thread Series - 8UN | |||

|---|---|---|---|---|---|---|

| Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | |

| 1/4 | 20 | 0.0318 | 28 | 0.0364 | -- | -- |

| 5/16 | 18 | 0.0524 | 24 | 0.0580 | -- | -- |

| 3/18 | 16 | 0.0775 | 24 | 0.0878 | -- | -- |

| 7/16 | 14 | 0.1063 | 20 | 0.1187 | ||

| 1/2 | 13 | 0.1419 | 20 | 0.1599 | ||

| 9/16 | 12 | 0.1820 | 18 | 0.2030 | ||

| 5/8 | 11 | 0.2260 | 18 | 0.2560 | ||

| 3/4 | 10 | 0.3340 | 16 | 0.3730 | ||

| 7/8 | 9 | 0.4620 | 14 | 0.5090 | ||

| 1 | 8 | 0.6060 | 12 | 0.6630 | ||

| 1 1/8 | 7 | 0.7630 | 12 | 0.8560 | 8 | 0.790 |

| 1 1/4 | 7 | 0.9690 | 12 | 1.0730 | 8 | 1.000 |

| 1 3/8 | 6 | 1.1550 | 12 | 1.3150 | 8 | 1.233 |

| 1 1/2 | 6 | 1.4050 | 12 | 1.5810 | 8 | 1.492 |

A Tensile stress areas are computed using the following formula: As = 0.7854 [D- (0.9743/n)]2

Where:

As = Tensile stress area, in.2,

D = Nominal size (basic major diameter), in., and,

n = number of threads per inch.

Stainless Steel :

AISI 302, 304, 304L,316, 316L, 310, 317, 317L, 321, 347, 410, 420,904L etc.

Duplex & Super Duplex Steel :

ASTM / ASME A815 UNS No. S31803, UNS No. S 32205, UNS No. S 31254, UNS No. S 31550, UNS No. S 32750, and UNS No. S 32760

Carbon Steel :

ASTM A307

Alloy Steel :

ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M

Nickel Alloy :

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3)

Nut Size (mm) |

Diameter* (mm) |

Height (mm) |

||

|---|---|---|---|---|

Hex Nut |

Jam Nut |

Nylock Nut |

||

2 |

4 |

1.6 |

1.2 |

- |

2.5 |

5 |

2 |

1.6 |

- |

3 |

5.5 |

2.4 |

1.8 |

4 |

4 |

7 |

3.2 |

2.2 |

5 |

5 |

8 |

4 |

2.7 |

5 |

6 |

10 |

5 |

3.2 |

6 |

7 |

11 |

5.5 |

3.5 |

- |

8 |

13 |

6.5 |

4 |

8 |

10 |

17 |

8 |

5 |

10 |

12 |

19 |

10 |

6 |

12 |

14 |

22 |

11 |

7 |

14 |

16 |

24 |

13 |

8 |

16 |

18 |

27 |

15 |

9 |

18.5 |

20 |

30 |

16 |

10 |

20 |

* This is the diameter across the flats. It is also the size of wrench to use. |

||||

Nominal Size or Basic Major Thread Diameter

| F |

G |

H |

||||||

|---|---|---|---|---|---|---|---|---|---|

Width Across Flats |

Width Across Corners |

Thickness |

|||||||

Basic |

Max |

Min |

Max |

Min |

Basic |

Max |

Min |

||

1/4 |

.2500 |

7/16 |

.438 |

.428 |

.505 |

.488 |

7/32 |

.226 |

.212 |

5/16 |

.3125 |

1/2 |

.500 |

.489 |

.577 |

.557 |

17/64 |

.273 |

.258 |

3/8 |

.3750 |

9/16 |

.562 |

.551 |

.650 |

.628 |

21/64 |

.337 |

.479 |

7/16 |

.4375 |

11/16 |

.688 |

.675 |

.794 |

.768 |

3/8 |

.385 |

.365 |

1/2 |

.5000 |

3/4 |

.750 |

.736 |

.866 |

.840 |

7/16 |

.448 |

.427 |

9/16 |

.5625 |

7/8 |

.875 |

.861 |

1.010 |

.982 |

31/64 |

.496 |

.473 |

5/8 |

.6250 |

15/16 |

.938 |

.922 |

1.083 |

1.051 |

35/64 |

.559 |

.535 |

3/4 |

.7500 |

1-1/8 |

1.125 |

1.088 |

1.299 |

1.240 |

41/64 |

.665 |

.617 |

7/8 |

.8750 |

1-5/16 |

1.312 |

1.269 |

1.516 |

1.447 |

3/4 |

.776 |

.724 |

1 |

1.0000 |

1-1/2 |

1.500 |

1.450 |

1.732 |

1.653 |

55/64 |

.887 |

.831 |

1-1/8 |

1.1250 |

1-11/16 |

1.688 |

1.631 |

1.949 |

1.859 |

31/32 |

.999 |

.939 |

1-3/8 |

1.3750 |

2-1/16 |

2.062 |

1.994 |

2.382 |

2.273 |

1-11/64 |

1.206 |

1.138 |

1-1/2 |

1.500 |

2-1/4 |

2.250 |

2.175 |

2.598 |

2.480 |

1-9/32 |

1.ASTM A194 GR. 8 |

1.245 |

1-5/8 |

1.6250 |

2-7/16 |

2.438 |

2.356 |

2.815 |

2.686 |

1-25/64 |

1.429 |

1.353 |

1-3/4 |

1.7500 |

2-5/8 |

2.625 |

2.538 |

3.031 |

2.893 |

1-1/2 |

1.540 |

1.460 |

2 |

2.0000 |

3 |

3.000 |

2.900 |

3.464 |

3.306 |

1-23/32 |

1.763 |

1.675 |

2-1/4 |

2.2500 |

3-3/8 |

3.375 |

3.263 |

3.897 |

3.719 |

1-15/16 |

1.986 |

1.890 |

2-1/2 |

2.5000 |

3-3/4 |

3.750 |

3.625 |

4.330 |

4.133 |

2-5/32 |

2.209 |

2.105 |

2-3/4 |

2.7500 |

4-1/8 |

4.125 |

3.988 |

4.763 |

4.546 |

2-3/8 |

2.431 |

2.319 |

| Alloy | Condition |

|---|---|

| All Alloys in Copper | As formed or stress relieved at manufacturer's option |

| Nickel Alloys: | |

| Monel 400 and Monel 405 | As formed or stress relieved at manufacturer's option |

| Monel K500 | Solution annealed and aged |

| Inconel 625 | Annealed |

| Aluminum Alloys: | |

| 2024-T4 | Solution treated and naturally aged |

| 6061-T6 | Solution treated and artificially aged |

| 6262-T73 | Solution treated and stablilized |

| Titanium | As Formed |

| Alloy | Test Method |

|---|---|

| Copper | E52, E54, E62, E75, E478 |

| Aluminum | E34, E101, E227 |

| Nickel | E38, E76, E354 |

| Titanium | E120, E1409 |

| ASME B18.1.1 | Small Solid Rivets | ASME B18.8.1 | Clevis Pins and Cotter Pins |

|---|---|---|---|

| ASME B18.1.2 | Large Rivets | ASME B18.8.2 | Taper Pins, Dowel Pins, Straight Pins, Grooved Pins and Spring Pins |

| ASME B18.2.1 | Square and Hex Bolts and Screws | ASME B18.9 | Plow Bolts |

| ASME B18.2.2 | Square and Hex Nuts | ASME B18.10 | Track Bolts and Nuts |

| ASME B18.2.6 | Fasteners for use in Structural Applications | ASME B18.11 | Miniature Screws |

| ASME B18.3 | Socket Cap, Shoulder and Set Screws | ASME B18.13 | Screws and Washer Assemblies (Sems) |

| ASME B18.5 | Round Head Bolts | ASME B18.15 | Forged Eyebolts |

| ASME B18.6.2 | Slotted Head Cap Screws, Square Head Set Screws, and Slotted Headless Set Screws | ASME B18.17 | Wing Nuts, Thumb Screws and Wing Screws |

| ASME B18.6.3 | Machine Screws and Machine Screws Nuts | ASME B18.21.1 | Lock Washers |

| ASME B18.6.4 | Thread Forming and Thread Cutting Tapping Screws and Metallic Drive Screws | ASME B18.22.1 | Plain Washers |

| ASME B18.7 | General Purpose Semi- Tubular Rivets, Full Tubular Rivets, Split Rivets and Rivet Caps | ASME B18.23.1 | Beveled Washers |

| Nominal Size, inch. | Coarse Threads – UNC | Fine Threads – UNF | 8 Thread Series – 8UN | |||

|---|---|---|---|---|---|---|

| Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | Threads / inch | Stress AreaA, in2 | |

| 1/4 | 20 | 0.0318 | 28 | 0.0364 | — | — |

| 5/16 | 18 | 0.0524 | 24 | 0.0580 | — | — |

| 3/18 | 16 | 0.0775 | 24 | 0.0878 | — | — |

| 7/16 | 14 | 0.1063 | 20 | 0.1187 | ||

| 1/2 | 13 | 0.1419 | 20 | 0.1599 | ||

| 9/16 | 12 | 0.1820 | 18 | 0.2030 | ||

| 5/8 | 11 | 0.2260 | 18 | 0.2560 | ||

| 3/4 | 10 | 0.3340 | 16 | 0.3730 | ||

| 7/8 | 9 | 0.4620 | 14 | 0.5090 | ||

| 1 | 8 | 0.6060 | 12 | 0.6630 | ||

| 1 1/8 | 7 | 0.7630 | 12 | 0.8560 | 8 | 0.790 |

| 1 1/4 | 7 | 0.9690 | 12 | 1.0730 | 8 | 1.000 |

| 1 3/8 | 6 | 1.1550 | 12 | 1.3150 | 8 | 1.233 |

| 1 1/2 | 6 | 1.4050 | 12 | 1.5810 | 8 | 1.492 |

| Nominal Nut Diameter | Metric Coarse Threads | |

|---|---|---|

| Thread Pitch | Stress AreaA, mm2 | |

| M6 | 1P | 20.1 |

| M8 | 1.25P | 36.6 |

| M10 | 1.5P | 58.0 |

| M12 | 1.75P | 84.3 |

| M14 | 2P | 115 |

| M16 | 2P | 157 |

| M20 | 2.5P | 245 |

| M24 | 3P | 353 |

| M30 | 3.5P | 561 |

| M36 | 4P | 817 |

No. |

Description |

|---|---|

DIN 84 |

Slotted Cheese Head Machine Screws |

DIN 85 |

Slotted Pan Head Machine Screws |

DIN 94 |

Cotter Pin |

DIN 125A |

Flat Washer (without Chamfer) |

DIN 125B |

Flat Washer (with Chamfer) |

DIN 127B |

Split Lock Washer |

DIN 137B |

Spring Wave Washer |

DIN 315 |

Wing Nut |

DIN 439B |

Machine Screws Hex Nut, Finished Hex Jam Nut |

DIN 911 |

Long Arm Hex Key |

DIN 912 |

Hex Socket Head Cap Screws |

DIN 916 |

Hex Socket Set Screws |

DIN 931 |

Hex Head Cap Screws Partially Threaded |

DIN 933 |

Hex Head Cap Screws Fully Threaded |

DIN 934 |

Finished Hex Nut |

DIN 939 |

Double End Stud |

DIN 960 |

Hex Head Cap Screws Partially Threaded |

DIN 961 |

Hex Head Cap Screws Fully Threaded |

DIN 963 |

Slotted Flat Head Machine Screws |

DIN 964 |

Slotted Oval Head Machine Screws |

DIN 965 |

Phillips Flat Head Machine Screws |

DIN 966 |

Phillips Oval Head Machine Screws |

DIN 975 |

Threaded Rod |

DIN 980V |

Hex Steel Prevailing Torque Lock Nut |

DIN 985 |

Hex Nylon Insert Lock Nut |

DIN 6334 |

Rod Coupling Nut |

DIN 6797A |

External Tooth Lock Washer |

DIN 6797J |

Internal Tooth Lock Washer |

DIN 6912 |

Hex Low Socket Head Cap Screws |

DIN 6921 |

Hex Flange Head Screws |

DIN 6923 |

Hex Flange Nut |

ISO 7379 |

Hex Socket Head Shoulder Screws |

ISO 7380 |

Hex Button Socket Head Cap Screws |

DIN 7985 |

Phillips Pan Head Machine Screws |

DIN 7991 |

Hex Flat Socket Head Cap Screws |

| Product | Proof Stress, ksi | Test Conducted Using Full Size Product | |

|---|---|---|---|

| Jam, slotted and castle nuts | All | A | -- |

| All other nuts | Up to 120 | -- | A |

| All other nuts | Over 120 | A | -- |

Metric |

Closest Inch |

|---|---|

M1.4-0.3 |

0-80 (Larger) |

M2-0.4 |

1-64 (Smaller) |

M2.5-0.45 |

3-56 (Larger) |

M3-0.5 |

4-48 (Smaller) |

M3.5-0.6 |

6-40 (Same) |

M4-0.7 |

8-36 (Larger) |

M5-0.8 |

10-32 (Smaller) |

M6-1.0 |

1/4-28 (Larger) |

M7-1.0 |

1/4-28 (Smaller) |

M8-1.25 |

5/16-18 (Smaller) |

M10-1.5 |

3/8-16 (Smaller) |

M12-1.75 |

1/2-13 (Larger) |

M14-2.0 |

9/16-12 (Larger) |

M16-2.0 |

5/8-11 (Smaller) |

M18-2.5 |

3/4-10 (Larger) |

M20-2.5 |

3/4-10 (Smaller) |

M22-2.5 |

7/8-9 (Larger) |

M24-3.0 |

1-8 (Larger) |

M30-3.5 |

1 1/8-7 (Smaller) |

M36-4.0 |

1 3/8-6 (Smaller) |

| Composition, % Nickel and Nickel Base Alloys |

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS Designation | Alloy | General Name | Aluminum | Carbon, max | Chromium | CopperA | Iron, max | Manganese, max | NickelA | Phosphorus, max | Silicon, max | Titanium | Cobalt, max | Molybdenum | Sulfur, max | Vanadium | Tungsten |

| N06625 | 625C | Ni-Cr-No-Cb | 0.40 max | 0.010 max | 20.0 - 23.0 | -- | 5.00 | 0.50 | 58.0 min | 0.040 | 0.50 | 0.40 max | 1.00 | 8.0 - 10.0 | 0.015 | -- | 3.2 - 4.2 |

| Alloy | Mechanical Property Marking | Nominal Thread Diameter, inch | HardnessA | Proof Stress, min, ksi |

|---|---|---|---|---|

| Inconel 625 | ||||

| Ni 625 | F 467AC | all | 85 HRB - 35 HRC | 60 |

A For Aluminum and titanium alloys hardness values are for information only.

B Aluminum alloy 2024-T4 shall be supplied in naturally aged condition. This material is not recommended for nuts in sizes greater than 1/4 ( 0.250) inch.

Alloy Group |

Alloy Designation |

Alloy Type |

|---|---|---|

1 |

303, 304, 304L, 305, 384, XM1, 18-9LW, 302HQ, 303Se |

Austenitic |

2 |

316, 316L |

Austenitic |

3 |

321, 347 |

Austenitic |

4 |

430, 430F |

Ferritic |

5 |

410, 416, 416Se |

Martensitic |

6 |

431 |

Martensitic |

7 |

630 (17-4) |

Precipitation Hardening |

|

|