There are two classes under specification ASTM A193, Grade B8 that is class 1 and class 2. The grade B8 in ASTM A193 Grade B8 Class 2 Bolts suggests that alloy 304 was the material used. Stainless steel alloy Alloy 304 is very adaptable. Additionally, theA193 B8 Class 2 Materialis one among the most widely used alloys in the world, in part due to its cost-effectiveness. Despite the fact that both types of fasteners are carbide solution treated, there is just one distinction between the twoASME SA193 B8 Class 2 Nuts have been strain hardened.

Strain hardening or work hardening in the A193 B8 Class 2 Heavy Hex Boltstakes place by plastic deformation. Dislocation motions and dislocation generation occur during plastic deformation in the crystal structure of theA193 B8 Cl2 Strain Hardened Studs, which in this instance is 304 alloy. It is possible to boost a material's ultimate strength by strain hardening it.ASTM A193 B8 Class 2 Fasteners. Carbide solution treatment is also referred to as a solution annealing process.

In this process, the material is treated to heat as high as a temperature range of 1900ºF to 2050ºF. The heating process includes holding the ASME SA193 Grade B8 Class 2 Bolts for a duration of 1.5 hours. At the conclusion of heat treatment, the material is to undergo quenching. Quenching the ASTM A193 B8 Class 2 Bolts could be done either with the use of some amount of water or a gas fan. By performing a carbide solution treatment on grade 304 stainless steel, the A193 B8 Class 2 Stud Bolts could achieve toughness in either cryogenic or low temperature settings.

Compare Astm A193 Grade B8 Class 2 Bolts price with ASTM A193 Grade B6 Bolts price list

| Standard | IS, ANSI, ASTM DIN, ISO, JIS, GB, ASME, BS, UNI and all International Standards |

|---|---|

| Threads: | BSF, UNF METRIC, UNC, BSW or as required |

| Standard | ANSI – American National Standards Institute

DIN:DIN 933, DIN 931, DIN 970, DIN 934 UTS – Unified Thread Standard : UNF, NPT, NPTF, UNS, UNC, UNEF ISO – International Organization for Standardization ISO 4033, : ISO 4032, JIS standards |

| Fasteners/ Bolts Size | M10, M4, M16, M36 M2.5, M6, M30, M12, M8, M14, M2, M3, M20, M24, M5 to M160 |

| Length | 3 mm to 200 mm |

| Head drive: | Phillips, Slotted, Phillips/Slot, Six-Lobe etc |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Finishing | Zinc white, (yellow, black, blue), black oxide,

Dacroment, Geometry, plated zinc-nickel, anodizing, nickel plated, Stainless steel: Passivated Self-Colour, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, Stainless Steel, some special one like DACROMET and Mechanically Applied coating |

| raw materials of Source | JSPL, Usha Martin, Tata Steel, Mukund Steel, RINL, Dhamm Steel etc. |

| Form | Square, Hex, Threading as per Gauge, Round Etc. |

| Process of Production | M2-M24: Cold Froging, hot forging M24-M100, machining and CNC for Customized connecting element |

| Surface Coating |

|

| Packing | IN BULK: pallet, canton, carton / Small Boxs / pallet or customer request |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Stainless Steel Astm A193 Gr B8m Class 2 Slotted Hex Bolt -m10x50mm Long Full Thread | 162 | 2.20 | 1.80 |

| Stainless Steel Astm A193 Gr B8m Class 2 Heavy Hex Bolt -5/8 X90 Mm Long Full Thread | 385 | 5.24 | 4.28 |

| Stainless Steel Astm A193 Gr B8m Class 2 hex Bolt -m12x40mm Long Full Thread | 182 | 2.48 | 2.02 |

| Astm Sa193 Gr.b8m Class 2/astm Sa194 Gr.8m Hex Bolt With 1 Heavy Hex Nut,1 Locknut (Thin Nut)and 2 Flat Washers : M14 X | 362 | 4.92 | 4.02 |

| Astm Sa193 Gr.b8m Class 2/astm Sa194 Gr.8m Hex Bolt With 1 Heavy Hex Nut,1 Locknut (Thin Nut)and 2 Flat Washers : M16 X | 395 | 5.37 | 4.39 |

| M20 X 100 Din 931 Hex Bolts Astm A193 Grade B8 Class 2 | 120 | 1.63 | 1.33 |

| M20 X 80 Din 931 Hex Bolts Astm A193 Grade B8 Class 2 | 95 | 1.29 | 1.05 |

| Stainless Steel Stud Bolt To Astm A 193gr B8m-class 2 With Hex Nut To Astm A 194 Gr 8m With Washer Size : 1dia X 165 M | 3,599 | 48.95 | 39.96 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 1/2 (Unc) X 30mm Long(Fully Threaded) | 38 | 0.52 | 0.42 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 7/8 (Unc) X 65mm Long(Fully Threaded) | 251 | 3.41 | 2.79 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 7/8 (Unc) X 120mm Long (Fully Threaded) | 356 | 4.84 | 3.95 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 5/8 (Unc) X 35mm Long(Fully Threaded) | 88 | 1.20 | 0.98 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 5/8 (Unc) X 50mm Long(Fully Threaded) | 100 | 1.36 | 1.11 |

| Stainless Steel Astm A 193 B8 Class 2 Heavy Hex Bolt :- 1 (Unc) X 120mm Long(Fully Threaded) | 477 | 6.49 | 5.30 |

| Bolt, Nut & Washer Made By Stainless steel Hex Bolt Astm A 193,b8m Class 2,m-16x90 | 69 | 0.94 | 0.77 |

| Bolt, Nut & Washer Made By Stainless steel Hex Bolt Astm A 193,b8m Class 2,m-20x90 | 101 | 1.37 | 1.12 |

| Bolt, Nut & Washer Made By Stainlesssteel Hex Bolt Astm A 193,b8m Class 2, Mclass2,m-16x80 | 70 | 0.95 | 0.78 |

| Nut Specification | Washer Specification |

|---|---|

| ASTM A194 Grade 8 | ASTM A240 TP304 |

NOMINAL SIZE (D) |

BODY DIAMETER |

HEAD THICKNESS |

ACROSS THE FLATS |

ACROSS BOLTS CORNERS |

||||

|---|---|---|---|---|---|---|---|---|

D (MAX) |

D (MIN) |

H (MAX) |

H (MIN) |

F (MAX) |

F (MIN) |

C (MAX) |

C (MIN) |

|

m10 |

10.00 |

9.78 |

6.63 |

6.17 |

17.00 |

15.73 |

18.48 |

17.77 |

m12 |

12.00 |

11.73 |

7.76 |

4.24 |

19.00 |

17.73 |

20.78 |

20.03 |

m14 |

14.00 |

13.73 |

9.09 |

8.51 |

22.00 |

20.67 |

24.25 |

23.35 |

m16 |

16.00 |

15.73 |

10.32 |

9.68 |

24.00 |

23.67 |

27.71 |

26.75 |

m20 |

20.00 |

19.67 |

12.88 |

12.12 |

30.00 |

29.16 |

34.64 |

32.95 |

m24 |

24.00 |

23.67 |

15.44 |

14.56 |

36.00 |

35.00 |

41.57 |

39.55 |

m30 |

30.00 |

29.67 |

19.48 |

17.92 |

46.00 |

45.00 |

53.12 |

50.85 |

m36 |

36.00 |

35.61 |

23.38 |

21.63 |

55.00 |

53.80 |

63.51 |

60.79 |

m42 |

42.00 |

41.38 |

26.97 |

25.03 |

65.00 |

62.90 |

75.06 |

71.71 |

m48 |

48.00 |

47.38 |

31.07 |

28.93 |

75.00 |

72.60 |

86.60 |

82.76 |

m56 |

56.00 |

55.26 |

36.2 |

33.80 |

85.00 |

82.20 |

98.15 |

93.71 |

m64 |

64.00 |

63.26 |

41.32 |

38.68 |

95.00 |

91.80 |

109.70 |

104.65 |

m72 |

72.00 |

71.26 |

46.45 |

43.55 |

105.00 |

101.40 |

121.24 |

115.60 |

m80 |

80.00 |

79.26 |

51.58 |

48.42 |

115.00 |

111.00 |

132.72 |

126.54 |

m90 |

90.00 |

89.13 |

57.74 |

54.26 |

130.00 |

125.50 |

150.11 |

143.07 |

m100 |

90.00 |

99.13 |

63.9 |

60.10 |

145.00 |

140.00 |

167.43 |

159.60 |

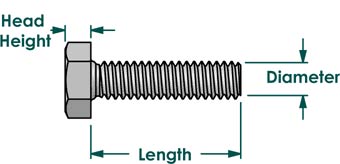

Diameter (D) |

Body Diameter (D) |

Across the Flats (F) |

Across the Corners © |

Head Height (H) |

Thread Lengths (T) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

MAX |

MIN |

MAX |

MIN |

MAX |

MIN |

MAX |

MIN |

< 6” |

> 6” |

|

1/2 |

0.515 |

0.482 |

0.875 |

0.85 |

1.01 |

0.969 |

0.364 |

0.302 |

1.25 |

1.5 |

5/8 |

0.642 |

0.605 |

1.062 |

1.031 |

1.227 |

1.175 |

0.444 |

0.378 |

1.5 |

1.75 |

3/4 |

0.768 |

0.729 |

1.25 |

1.212 |

1.443 |

1.383 |

0.524 |

0.455 |

1.75 |

2 |

7/8 |

0.895 |

0.852 |

1.438 |

1.394 |

1.66 |

1.589 |

0.604 |

0.531 |

2 |

2.25 |

1 |

1.022 |

0.976 |

1.625 |

1.575 |

1.876 |

1.796 |

0.7 |

0.591 |

2.25 |

2.5 |

1 1/8 |

1.149 |

1.098 |

1.812 |

1.756 |

2.093 |

2.002 |

0.78 |

0.658 |

2.5 |

2.75 |

1 1/4 |

1.277 |

1.223 |

2 |

1.938 |

2.309 |

2.209 |

0.876 |

0.749 |

2.75 |

3 |

1 3/8 |

1.404 |

1.345 |

2.188 |

2.119 |

2.526 |

2.416 |

0.94 |

0.81 |

3 |

3.25 |

1 1/2 |

1.531 |

1.47 |

2.375 |

2.3 |

2.742 |

2.622 |

1.036 |

0.902 |

3.25 |

3.5 |

1 3/4 |

1.785 |

1.716 |

2.75 |

2.662 |

3.175 |

3.035 |

1.196 |

1.054 |

3.75 |

4 |

2 |

2.039 |

1.964 |

3.125 |

3.025 |

3.608 |

3.449 |

1.388 |

1.175 |

4.25 |

4.5 |

2 1/4 |

2.305 |

2.214 |

3.5 |

3.388 |

4.041 |

3.862 |

1.548 |

1.327 |

4.75 |

5 |

2 1/2 |

2.559 |

2.461 |

3.875 |

3.75 |

4.474 |

4.275 |

1.708 |

1.479 |

5.25 |

5.5 |

2 3/4 |

2.827 |

2.711 |

4.25 |

4.112 |

4.907 |

4.688 |

1.869 |

1.632 |

5.75 |

6 |

3 |

3.081 |

2.961 |

4.625 |

4.475 |

5.34 |

5.102 |

2.06 |

1.815 |

6.25 |

6. |

|

TORQUE FT-LBS – ASTM A193 GRADE B8 Class 2 STUD BOLTS

|

|||

|---|---|---|---|

|

BOLT

DIA |

TORQUE FT-LBS

|

||

|

30% Initial

Torque |

70%

Torque |

100% Final

Torque |

|

|

1/2

|

16

|

36

|

52

|

|

9/16

|

23

|

53

|

75

|

|

5/8

|

31

|

73

|

104

|

|

3/4

|

55

|

129

|

184

|

|

7/8

|

71

|

166

|

237

|

|

1

|

107

|

249

|

356

|

|

1⅛

|

127

|

297

|

424

|

|

1¼

|

179

|

417

|

596

|

|

1⅜

|

186

|

435

|

622

|

|

1½

|

246

|

574

|

821

|

|

19/16

|

168

|

392

|

560

|

|

1⅝

|

191

|

445

|

636

|

|

1¾

|

240

|

561

|

801

|

|

1⅞

|

298

|

696

|

994

|

|

2

|

366

|

853

|

1219

|

|

2¼

|

529

|

1234

|

1762

|

|

2½

|

733

|

1709

|

2442

|

|

2¾

|

986

|

2300

|

3285

|

|

3

|

1289

|

3008

|

4297

|

Engineers Stud Metal End =2 D Sk6 Metric Coarse DIN 83

| d | b | c l<125 | c l<125<200 | c l 200> |

|---|---|---|---|---|

| M4 | 8.0000 | 14.0000 | 20.0000 | |

| M5 | 10.0000 | 16.0000 | 22.0000 | |

| M6 | 12.0000 | 18.0000 | 24.0000 | |

| M7 | 14.0000 | 20.0000 | 26.0000 | |

| M8 | 16.0000 | 22.0000 | 28.0000 | |

| M10 | 20.0000 | 26.0000 | 32.0000 | 45.0000 |

| M12 | 24.0000 | 30.0000 | 36.0000 | 49.0000 |

| M14 | 28.0000 | 34.0000 | 40.0000 | 53.0000 |

| M16 | 32.0000 | 38.0000 | 44.0000 | 57.0000 |

| M18 | 36.0000 | 42.0000 | 48.0000 | 61.0000 |

| M20 | 40.0000 | 46.0000 | 52.0000 | 65.0000 |

| M22 | 44.0000 | 50.0000 | 56.0000 | 69.0000 |

| M24 | 48.0000 | 54.0000 | 60.0000 | 73.0000 |

Hexagon Full Nut BSW BS 1083

| d | e | s max | s min | m max | m min |

|---|---|---|---|---|---|

| 1/4" | 0.5100 | 0.4450 | 0.4380 | 0.2000 | 0.1900 |

| 5/16" | 0.6100 | 0.5250 | 0.5180 | 0.2500 | 0.2400 |

| 3/8" | 0.6900 | 0.6000 | 0.5920 | 0.3120 | 0.3020 |

| 7/16" | 0.8200 | 0.7100 | 0.7020 | 0.3750 | 0.3650 |

| 1/2" | 0.9500 | 0.8200 | 0.8120 | 0.4370 | 0.4270 |

| 9/16" | 1.0600 | 0.9200 | 0.9120 | 0.5000 | 0.4900 |

| 5/8" | 1.1700 | 1.0100 | 1.0000 | 0.5620 | 0.5520 |

| 3/4" | 1.3900 | 1.2000 | 1.1900 | 0.6870 | 0.6770 |

| 7/8" | 1.5000 | 1.3000 | 1.2880 | 0.7500 | 0.7400 |

| 1" | 1.7100 | 1.4800 | 1.4680 | 0.8750 | 0.8650 |

| 1.1/8" | 1.9300 | 1.6700 | 1.6400 | 1.0000 | 0.9900 |

| 1.1/4" | 2.1500 | 1.8600 | 1.8150 | 1.1250 | 1.1050 |

| 1.3/8" | 2.3700 | 2.0500 | 2.0050 | 1.2500 | 1.2300 |

| 1.1/2" | 2.5600 | 2.2200 | 2.1750 | 1.3750 | 1.3550 |

| 1.3/4" | 2.9800 | 2.5800 | 2.5200 | 1.6250 | 1.6050 |

| 2" | 3.1900 | 2.7600 | 2.7000 | 1.7500 | 1.7300 |

| Class | Heat Treatment Procedure |

| Class 2 | Carbide Solution Treatment & Strain Hardened |

Flat Washer Metric Form B BS 4320

| D | d1 | d2 | d3 |

|---|---|---|---|

| M1.0 | 1.1000 | 2.5000 | - |

| M1.2 | 1.3000 | 3.0000 | - |

| M1.4 | 1.5000 | 3.0000 | - |

| M1.6 | 1.7000 | 4.0000 | - |

| M2 | 2.2000 | 5.0000 | - |

| M2.2 | 2.4000 | 5.0000 | - |

| M2.5 | 2.7000 | 6.5000 | - |

| M3 | 3.6200 | 7.0000 | - |

| M3.5 | 3.7000 | 7.0000 | - |

| M4 | 4.3000 | 9.0000 | - |

| M4.5 | 4.8000 | 9.0000 | - |

| M5 | 5.3000 | 10.0000 | - |

| M6 | 6.4000 | 12.5000 | 0.8000 |

| M7 | 7.4000 | 14.0000 | 0.8000 |

| M8 | 8.4000 | 17.0000 | 1.0000 |

| M10 | 10.5000 | 21.0000 | 1.2500 |

| M12 | 13.0000 | 24.0000 | 1.6000 |

| M14 | 15.0000 | 28.0000 | 1.6000 |

| M16 | 17.0000 | 30.0000 | 2.0000 |

| M18 | 19.0000 | 34.0000 | 2.0000 |

| M20 | 21.0000 | 37.0000 | 2.0000 |

| M22 | 23.0000 | 39.0000 | 2.0000 |

| M24 | 25.0000 | 44.0000 | 2.5000 |

| M27 | 28.0000 | 50.0000 | 2.5000 |

| M30 | 31.0000 | 56.0000 | 2.5000 |

| M33 | 34.0000 | 60.0000 | 3.0000 |

| M36 | 37.0000 | 66.0000 | 3.0000 |

| M39 | 40.0000 | 72.0000 | 3.0000 |

| Class | Marking |

|---|---|

| Class 2 | "Simplex Steel" Manufacturer's Logo & "B8SH" Grade Marking |

| Grade and Class | Diameter | Tensile Strength Min KSI | Yield Strength 0.2% Offset KSI | Elongation in 4D, Min, % | Reduction of Area Min, % | Hardness Max Brinell | Hardness Max Rockwell |

|---|---|---|---|---|---|---|---|

| B5 | up to 4" incl | 100 | 80 | 16 | 50 | - | - |

| B6 | up to 4" incl | 110 | 85 | 15 | 50 | - | - |

| B6X | up to 4" incl | 90 | 70 | 16 | 50 | - | C26 |

| B7 | to 2-1/2" | 125 | 105 | 16 | 50 | - | C35 |

| over 2-1/2 to 4" | 115 | 95 | 16 | 50 | - | C35 | |

| over 4" to 7" | 100 | 75 | 18 | 50 | - | C35 | |

| B7M | up to 4" incl | 100 | 80 | 18 | 50 | 235 | B99 |

| over 4" to 7" | 100 | 75 | 18 | 50 | 235 | B99 | |

| B16 | to 2-1/2" | 125 | 105 | 18 | 50 | 321 | C35 |

| over 2-1/2" to 4" | 110 | 95 | 17 | 45 | 321 | C35 | |

| over 4" to 7" | 100 | 85 | 16 | 45 | 321 | C35 | |

| Classes 1 and 1D: B8, B8M, B8P, B8LN, B8ML | ALL | 75 | 30 | 30 | 50 | 223 | B96 |

| Class 1: B8C, B8T | ALL | 75 | 30 | 30 | 50 | 223 | B96 |

| Class 1A: B8A, B8CA, B8MA, B8PA, B8TA, B8LNA, B8MLNA, B8NA, B8MNA, B8MLCuNA | ALL | 75 | 30 | 30 | 50 | 192 | B90 |

| Classes 1B & 1D: B8N, B8MN, B8MLCuN | ALL | 80 | 35 | 30 | 40 | 223 | B96 |

| Class 1C and 1D: B8R | ALL | 100 | 55 | 35 | 55 | 271 | C28 |

| Class 1C: B8RA | ALL | 100 | 55 | 35 | 55 | 271 | C28 |

| Classes 1C and 1D: B8S | ALL | 95 | 50 | 35 | 55 | 271 | C28 |

| Classes 1C: B8SA | ALL | 95 | 50 | 35 | 55 | 271 | C28 |

| Class 2: B8, B8C, B8P, B8T, B8N | to 3/4" | 125 | 100 | 12 | 35 | 321 | C35 |

| over 3/4" to 1" | 115 | 80 | 15 | 35 | 321 | C35 | |

| over 1" to 1-1/4" | 105 | 65 | 20 | 45 | 321 | C35 | |

| over 1-1/4 to 1-1/2" incl | 100 | 50 | 28 | 45 | 321 | C35 | |

| Class 2 B8M, B8MN, B8MLCuN | to 3/4" | 110 | 96 | 15 | 45 | 321 | C35 |

| over 3/4" to 1" | 100 | 80 | 20 | 45 | 321 | C35 | |

| over 1" to 1-1/4" | 95 | 65 | 25 | 45 | 321 | C35 | |

| over 1-1/4 to 1-1/2" incl | 90 | 50 | 30 | 45 | 321 | C35 | |

| Class 2B: B8, B8M2 | to 2" incl | 95 | 75 | 25 | 40 | 321 | C35 |

| over 2" to 2-1/2" incl | 90 | 65 | 30 | 40 | 321 | C35 | |

| over 2-1/2 " to 3" incl | 80 | 55 | 30 | 40 | 321 | C35 | |

| Class 2C: B8M3 | to 2" incl | 85 | 65 | 30 | 60 | 321 | C35 |

| over2" | 85 | 60 | 30 | 60 | 321 | C35 |

| Element | B8 Class 2 |

| Carbon | 0 - 0.15% |

| Manganese | 0 - 1.00% |

| Phosphorus, max | 0 - 0.040% |

| Sulfur, max | 0 - 0.03% |

| Silicon | 0 - 1.00% |

| Chromium | 11.5 - 13.5% |

| Nickel | - |

| Molybdenum | - |

| Mechanical Requirements, Inch Products | |||||||

|---|---|---|---|---|---|---|---|

| Class | Diameter | Tensile Strength, min, ksi | Yield Strength, min, ksi | Elongation in 4D min, % | Reduction of Area, min, % | Hardness, max | |

| 2 | 3/4 and under | 125 | 100 | 12 | 35 | 321 HBW | 35 HRC |

| Over ¾ to 1, incl. | 115 | 80 | 15 | 35 | |||

| Over 1 to 1-1/4, incl. | 105 | 65 | 20 | 35 | |||

| Over 1-1/4 to 1-1/2, incl. | 100 | 50 | 28 | 45 | |||

| Mechanical Requirements, Metric Products | |||||||

|---|---|---|---|---|---|---|---|

| Class | Diameter | Tensile Strength, min, ksi | Yield Strength, min, ksi | Elongation in 4D min, % | Reduction of Area, min, % | Hardness, max | |

| 2 | M20 and under | 860 | 690 | 12 | 35 | 321 HBW | 35 HRC |

| Over M20 to M24, incl. | 795 | 550 | 15 | 35 | |||

| Over M24 to M30, incl. | 725 | 450 | 20 | 35 | |||

| Over M30 to M36, incl. | 690 | 345 | 28 | 45 | |||

|

|