ASTM F2281 Bolts

Bolts are a practical tool, particularly because they can bind several parts together. However, the material used in its construction, the type of Bolts, and the standard employed will all affect how well the Bolts perform in any application. As to ASTM F2281 specification, the utilisation of ASTM F2281 Bolts is designed for use in situations where temperatures reach a maximum of 1800°F.

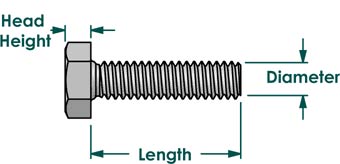

The dimensions given in the specification for the ASTM SF2281 Hex Boltsfeature a 1/4-inch or bigger diameter. The specification requires the production of in addition to the size and maximum temperature limits listed here: ASTM F2281 Hex Cap ScrewsBolts made of nickel alloys or stainless steel in a variety of grades that adhere to the required mechanical and chemical requirements. components used in the creation ofastm f2281 flange Bolts must also comply with the environmental requirements of the application.

Therefore, the specification also accounts for the use of ASTM F2281M Bolts in various corrosive environments. The ASTM F2281 Studs, along with Bolts, hex cap screws, etc are intended for use in applications involving both high temperature and heat resistance.

| Description | Price list |

| Stud Bolts Hex Bolts ASTM F2281 Alloy 316 316L 321 330 | US $ 0.1-1 / Piece |

| ASTM F2281 Alloy 347 410 416 430 430f Hex Bolts | US $ 0.1-1 / Piece |

| ASTM SF2281 Hex Bolts | US $ 0.01-0.2 / Piece |

| ASTM F2281 Bolts | US $ 0.06-0.1 / Piece |

| ASTM F2281 Hex Cap Screws | US $ 0.35-0.5 / Piece |

| ASTM F2281 Studs | US $ 0.25-0.3 / Piece |

| astm f2281 flange Bolts | US $ 0.02-0.08 / Piece |

| ASTM F2281M Bolts | US $ 0.1-5 / Piece |

| standards of British | BS 57 |

|---|---|

| standards of ISO | ISO 10642 |

| Length | 3 millimeter- 200 millimeter |

| Size |

M16, M5, M33, (M3.5), (M45), M20, M42, M4, (M22), (M27), (M14), M6, (M18), M36, M48, M12, M2, M3, M10, M24, M30, M8 M160 and as per need |

| F2281 Bolts Standard: |

ASTM, ANSI , ISO, DIN, GB, JIS, BS, IS and all International Standards |

| Threads | BSW, METRIC, UNC, BSF, UNF or as per need |

| UTS | UNF, NPT, UNC, UNS, UNEF, NPTF |

| DIN Standard | B.S. DIN 931, DIN 933, DIN 912, DIN 934, DIN 6923, DIN 603, DIN 7981, DIN 970, DIN916, DIN 7982, DIN 7985, DIN 913 |

| F2281 Bolts Tolerance | +/- 00.01 millimeter to +/- 00.05 millimeter |

| Dimensions | ASME B18.6.3 **Exception: shorter are fully threaded and 6 inches screws |

| Type | Round/ Pan/ Truss head/ Hex Head/ Oval |

| Head | Phillips/Slot,Six-Lobe, Phillips, Slotted etc |

| Finishing |

|

| F2281 Bolts Head | flat head, Pan head, hex head, oval head, phillips head |

| process of Production | Cold Heading, Wire Drawing, Heat Treatment, Insert tapping, Inspection, Packing, Surface Plating |

| Finish | ASTM A380/A380M |

| Manufacturers | GKW, SPAX® Screws, Kundan, Unbrako, Sundaram Precision, APL, EBY Fastener , Infasco Etc. |

| treatment of F2281 Bolts Surface |

|

| Uses | Wind tower, Railway, Automotive industry, Nuclear power, Electronic industry, Construction |

| F2281 Bolts Certificate provided |

|

| UNS Designation | Alloy Grade |

|---|---|

| S30403 | ASTM F2281 304L Type I Class A Bolts |

| S30400 | ASTM F2281 304 Type I Class A Bolts |

| N06601 | ASTM F2281 601 Type III Class C Bolts |

| S31603 | ASTM F2281 316L Type I Class A Bolts |

| S31600 | ASTM F2281 316 Type I Class A Bolts |

| S41600 | ASTM F2281 416 Type I Class B Bolts |

| S41000 | ASTM F2281 410 Type I Class B Bolts |

| S43000 | ASTM F2281 430 Type I Class C Bolts |

| S43100 | ASTM F2281 431 Type I Class B Bolts |

| S30900 | ASTM F2281 309 Type II Bolts |

| S66286 | ASTM F2281 660 Type III Class A Bolts |

| N07718 | ASTM F2281 718 Type III Class A Bolts |

| S43020 | ASTM F2281 430F Type I Class C Bolts |

| S32100 | ASTM F2281 321 Type II Bolts |

| N08330 | ASTM F2281 330 Type II Bolts |

| S34700 | ASTM F2281 347 Type II Bolts |

| S31000 | ASTM F2281 310 Type II Bolts |

| N06600 | ASTM F2281 600Type III Class B Bolts |

| d | ds | s | dc | k | b | L | |||

|---|---|---|---|---|---|---|---|---|---|

F2281 Bolts Nominal Diameter |

Thread Pitch |

Body Diameter |

Width Across Flats |

Flange Diameter |

Head Height |

Thread Length |

Lengths Under the Head |

||

(coarse) |

Max. |

Min. |

Max. |

Min. |

Max. |

Max. |

Nominal |

||

M6 |

1 |

6 |

5.82 |

10 |

9.78 |

14.2 |

6.6 |

18 |

10-60 |

M8 |

1.25 |

8 |

7.78 |

13 |

12.73 |

18 |

8.1 |

22 |

12-80 |

M10 |

1.5 |

10 |

9.78 |

15 |

14.73 |

22.3 |

9.2 |

26 |

16-80 |

M12 |

1.75 |

12 |

11.73 |

16 |

15.73 |

26.6 |

11.5 |

30 |

25-120 |

M14 |

2 |

14 |

13.73 |

18 |

17.73 |

30.5 |

12.8 |

34 |

30-120 |

M16 |

2 |

16 |

15.73 |

21 |

20.67 |

35 |

14.4 |

38 |

40-120 |

M20 |

2.5 |

20 |

19.67 |

27 |

26.67 |

43 |

17.1 |

46 |

40-120 |

| Fasteners Class 150 Flanges ASME B16.5 (Stud Bolts sizes) | Length of Stud Bolts | |||||||

|---|---|---|---|---|---|---|---|---|

| NPS | The diameter of Bolts Circle | Outside Diameter of Flange | Number of Bolts | The diameter of Bolts Holes | Diameter of Bolts | Ring Joint | Raised Face 0.06 in |

|

| 1/2 | 2 3/8 | 3 1/2 | 4 | 5/8 | 1/2 | – | 2 1/4 | |

| 3/4 | 2 3/4 | 3 7/8 | 4 | 5/8 | 1/2 | – | 2 1/2 | |

| 1 | 3 1/8 | 4 1/4 | 4 | 5/8 | 1/2 | 3 | 2 1/2 | |

| 1 1/4 | 3 1/2 | 4 5/8 | 4 | 5/8 | 1/2 | 3 1/4 | 2 3/4 | |

| 1 1/2 | 3 7/8 | 5 | 4 | 5/8 | 1/2 | 3 1/4 | 2 3/4 | |

| 2 | 4 3/4 | 6 | 4 | 3/4 | 5/8 | 3 3/4 | 3 1/4 | |

| 2 1/2 | 5 1/2 | 7 | 4 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 3 | 6 | 7 1/2 | 4 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 3 1/2 | 7 | 8 1/2 | 8 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 4 | 7 1/2 | 9 | 8 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 5 | 8 1/2 | 10 | 8 | 7/8 | 3/4 | 4 1/4 | 3 3/4 | |

| 6 | 9 1/2 | 11 | 8 | 7/8 | 3/4 | 4 1/2 | 4 | |

| 8 | 11 3/4 | 13 1/2 | 8 | 7/8 | 3/4 | 4 3/4 | 4 1/4 | |

| 10 | 14 3/4 | 16 | 12 | 1 | 7/8 | 5 | 4 1/2 | |

| 12 | 17 | 19 | 12 | 1 | 7/8 | 5 1/4 | 4 3/4 | |

| 14 | 18 3/4 | 21 | 12 | 1 1/8 | 1 | 5 3/4 | 5 1/4 | |

| 16 | 21 1/4 | 23 1/2 | 16 | 1 1/8 | 1 | 5 3/4 | 5 1/4 | |

| 18 | 22 3/4 | 25 | 16 | 1 1/4 | 1 1/8 | 6 1/4 | 5 3/4 | |

| 20 | 25 | 27 1/2 | 20 | 1 1/4 | 1 1/8 | 6 3/4 | 6 1/4 | |

| 24 | 29 1/2 | 32 | 20 | 1 1/4 | 1 1/4 | 7 1/4 | 6 3/4 | |

| Fasteners Class 300 Flanges ASME B16.5 | Length of Stud Bolts | |||||||

| NPS | The diameter of Bolts Circle | Outside Diameter of Flange | Number of Bolts | The diameter of Bolts Holes | Diameter of Bolts | Ring Joint | Raised Face 0.06 in |

|

| 1/2 | 2 5/8 | 3 3/4 | 4 | 5/8 | 1/2 | 3 | 2 1/2 | |

| 3/4 | 3 1/4 | 4 5/8 | 4 | 3/4 | 5/8 | 3 1/2 | 3 | |

| 1 | 3 1/2 | 4 7/8 | 4 | 3/4 | 5/8 | 3 1/2 | 3 | |

| 1 1/4 | 3 7/8 | 5 1/4 | 4 | 3/4 | 5/8 | 3 3/4 | 3 1/4 | |

| 1 1/2 | 4 1/2 | 6 1/8 | 4 | 7/8 | 3/4 | 4 | 3 1/2 | |

| 2 | 5 | 6 1/2 | 8 | 3/4 | 5/8 | 4 | 3 1/2 | |

| 2 1/2 | 5 7/8 | 7 1/2 | 8 | 7/8 | 3/4 | 4 1/2 | 4 | |

| 3 | 6 5/8 | 8 1/4 | 8 | 7/8 | 3/4 | 4 3/4 | 4 1/4 | |

| 3 1/2 | 7 1/4 | 9 | 8 | 7/8 | 3/4 | 5 | 4 1/4 | |

| 4 | 7 7/8 | 10 | 8 | 7/8 | 3/4 | 5 | 4 1/2 | |

| 5 | 9 1/4 | 11 | 8 | 7/8 | 3/4 | 5 1/4 | 4 3/4 | |

| 6 | 10 5/8 | 12 1/2 | 12 | 7/8 | 3/4 | 5 1/2 | 4 3/4 | |

| 8 | 13 | 15 | 12 | 1 | 7/8 | 6 | 5 1/2 | |

| 10 | 15 1/4 | 17 1/2 | 16 | 1 1/8 | 1 | 6 3/4 | 6 1/4 | |

| 12 | 17 3/4 | 20 1/2 | 16 | 1 1/4 | 1 1/8 | 7 1/4 | 6 3/4 | |

| 14 | 20 1/4 | 23 | 20 | 1 1/4 | 1 1/8 | 7 1/2 | 7 | |

| 16 | 22 1/2 | 25 1/2 | 20 | 1 3/8 | 1 1/4 | 8 | 7 1/2 | |

| 18 | 24 3/4 | 28 | 24 | 1 3/8 | 1 1/4 | 8 1/4 | 7 3/4 | |

| 20 | 27 | 30 1/2 | 24 | 1 3/8 | 1 1/4 | 8 3/4 | 8 | |

| 24 | 32 | 36 | 24 | 1 5/8 | 1 1/2 | 10 | 9 | |

| NOMINIMUMAL SIZE (D) | F2281 Bolts HEAD THICKNESS | BODY DIAMETER | ACROSS CORNERS | |||

|---|---|---|---|---|---|---|

| H (MAXIMUM) | H (MINIMUM) | D (MAXIMUM) | D (MINIMUM) | C (MAXIMUM) | C (MINIMUM) | |

| m12 | 7.076 | 4.024 | 12.000 | 11.073 | 20.078 | 20.003 |

| m10 | 6.063 | 6.017 | 10.000 | 9.078 | 18.048 | 17.077 |

| m16 | 10.032 | 9.068 | 16.000 | 15.073 | 27.071 | 26.075 |

| m14 | 9.009 | 8.051 | 14.000 | 13.073 | 24.025 | 23.035 |

| m30 | 19.048 | 17.092 | 30.000 | 29.067 | 53.012 | 50.085 |

| m20 | 12.088 | 12.012 | 20.000 | 19.067 | 34.064 | 32.095 |

| m48 | 31.007 | 28.093 | 48.000 | 47.038 | 86.060 | 82.076 |

| m42 | 26.097 | 25.003 | 42.000 | 41.038 | 75.006 | 71.071 |

| m80 | 51.058 | 48.042 | 80.000 | 79.026 | 132.072 | 126.054 |

| m64 | 41.032 | 38.068 | 64.000 | 63.026 | 109.070 | 104.065 |

| m100 | 63.09 | 60.010 | 90.000 | 99.013 | 167.043 | 159.060 |

| Material |

Grades |

ASTM Standards |

|---|---|---|

Alloy Steel Bolts |

B 7/ B 7M, B 6, 2, B 16, 2H, 2HM, B 7, GR 6, B 7M |

ASTM A 194/193 / ASME SA 194/193 GR |

Nickel Alloy Bolts |

UNS 8020 (ALLOY 20 / 20 CB 3), UNS 4400 (MONEL 400), UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 8825 (INCONEL 825), UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625) |

ASTM / ASME SB 164 /160 / 166 /425 / 574 / 446 / 472 |

Stainless Steel Bolts |

B 8C (SS 347), B 8 (304), B 8 T (SS 321), B 8M (SS 316), A 4, A 2 |

ASTM A 194/193 / ASME SA 194/193 |

Duplex Steel Bolts |

LENGTH: UPTO 5 METERS, size Range: M10 - M100 |

UNS NO. S32205, S31803 |

High-Temp Alloys Bolts |

19-9 DL, Discaloy, A286, 16-25-6, Nimonic 80, Titanium, Haynes 25, Mulitmet, Unitemp 252, Greek Ascalloy, Rene 41, Udimet 500, Inco 901, Inco 700, 235, Hastelloy X, RA 330, Waspaloy | |

Finish Bolts |

Zinc Plating, Black Oxide, Hot Dip Galvanized | |

Trademarks: |

Armco, Carpenter, DuPont, Cabot, INCO | |

Nonmetallic Materials: |

Kel-F, Acrylic, Lexan, Poly Vinyl Chloride, Polypropylene, Zytel 31, 105, 101, Teflon | |

Aluminum Alloys Bolts |

5052, 2024, 3003, 2011, 6061, 2014, 6053, 7075, 2017, 1100 | |

Copper Base Alloys Bolts |

Copper, Brasses: Free-cut, Yellow, Naval, Red, Bronze: Phosphor, Commercial, Aluminum, Silicon A & B, Manganese, Silicon-Aluminum, Munitz Metal, Ampco Alloys, Cupro-Nicles | |

| Bolts Size | TPI | Proof Load (lbs) | Clamp Load (lbs) | Tightening Torque (ft lbs) | ||

|---|---|---|---|---|---|---|

| Galv+Waxed | Galv | Plain | ||||

| 1⁄4 | 20 | 1,053 | 790 | 2 | 4 | 3 |

| 5⁄16 | 18 | 1,735 | 1,302 | 3 | 8 | 7 |

| 3⁄8 | 16 | 2,567 | 1,925 | 6 | 15 | 12 |

| 7⁄16 | 14 | 3,521 | 2,640 | 10 | 24 | 19 |

| 1⁄2 | 13 | 4,700 | 3,525 | 15 | 37 | 29 |

| 9⁄16 | 12 | 6,028 | 4,521 | 21 | 53 | 42 |

| 5⁄8 | 11 | 7,485 | 5,614 | 29 | 73 | 58 |

| 3⁄4 | 10 | 11,062 | 8,297 | 52 | 130 | 104 |

| 7⁄8 | 9 | 15,301 | 11,476 | 84 | 209 | 167 |

| 1 | 8 | 20,071 | 15,053 | 125 | 314 | 251 |

| 11⁄8 | 7 | 25,271 | 18,953 | 178 | 444 | 355 |

| 11⁄4 | 7 | 32,093 | 24,070 | 251 | 627 | 501 |

| 13⁄8 | 6 | 38,254 | 28,690 | 329 | 822 | 657 |

| 11⁄2 | 6 | 46,534 | 34,900 | 436 | 1,091 | 873 |

| 13⁄4 | 5 | 62,928 | 47,196 | 688 | 1,721 | 1,377 |

| 2 | 41⁄2 | 82,800 | 62,100 | 1,035 | 2,588 | 2,070 |

| 21⁄4 | 41⁄2 | 107,640 | 80,730 | 1,514 | 3,784 | 3,027 |

| 21⁄2 | 4 | 132,480 | 99,360 | 2,070 | 5,125 | 4,140 |

| 23⁄4 | 4 | 163,282 | 122,461 | 2,806 | 7,016 | 5,613 |

| 3 | 4 | 197,726 | 148,295 | 3,707 | 9,268 | 7,415 |

| 31⁄4 | 4 | 235,152 | 176,364 | 4,777 | 11,941 | 9,553 |

| 31⁄2 | 4 | 275,890 | 206,917 | 6,035 | 15,088 | 12,070 |

| 33⁄4 | 4 | 319,939 | 239,954 | 7,499 | 18,746 | 14,997 |

| 4 | 4 | 366,970 | 275,227 | 9,174 | 22,936 | 18,348 |

| AS PER IS 1363/67 MILLIMETER THREADS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| IN KILOGRAM FOR 100 NOS APPROXIMATE WEIGHT | ||||||||||

| LENGTH | DIAMETER | |||||||||

| M 6 | M 5 | M 10 | M 8 | M 14 | M 12 | M 18 | M 22 | M 16 | M 20 | |

| 16 millimeter | 0.743 | 0.448 | 3.211 | 1.590 | ||||||

| 20 millimeter | 0.812 | 0.598 | 3.411 | 1.711 | 4.892 | |||||

| 25 millimeter | 0.897 | 0.660 | 3.660 | 1.871 | 8.170 | 5.252 | ||||

| 30 millimeter | 1.010 | 0.737 | 3.912 | 2.070 | 9.690 | 5.574 | 10.707 | 18.657 | ||

| 35 millimeter | 1.120 | 0.804 | 4.223 | 2.271 | 10.000 | 5.974 | 16.026 | 11.416 | 19.608 | |

| 40 millimeter | 1.230 | 0.881 | 4.533 | 2.470 | 10.288 | 6.410 | 16.667 | 12.107 | 20.747 | |

| 45 millimeter | 1.340 | 0.958 | 4.840 | 2.671 | 10.504 | 6.859 | 17.241 | 12.821 | 21.739 | |

| 50 millimeter | 1.450 | 1.030 | 5.155 | 2.870 | 11.261 | 7.299 | 17.857 | 28.409 | 13.624 | 22.727 |

| 55 millimeter | 1.560 | 5.464 | 3.071 | 11.628 | 7.740 | 18.868 | 30.120 | 14.409 | 23.810 | |

| 60 millimeter | 1.670 | 5.774 | 3.270 | 12.255 | 8.183 | 20.000 | 32.051 | 15.244 | 25.126 | |

| 65 millimeter | 1.781 | 6.083 | 3.472 | 12.626 | 8.621 | 21.008 | 34.014 | 16.026 | 26.455 | |

| 70 millimeter | 1.890 | 6.394 | 3.671 | 12.987 | 9.058 | 22.124 | 35.461 | 16.835 | 27.778 | |

| 75 millimeter | 2.000 | 6.702 | 3.873 | 13.228 | 9.506 | 23.256 | 39.063 | 17.606 | 29.070 | |

| 80 millimeter | 2.111 | 7.013 | 4.072 | 13.889 | 10.000 | 24.510 | 40.000 | 18.248 | 30.303 | |

| 90 millimeter | 7.634 | 4.472 | 14.925 | 10.917 | 26.042 | 41.667 | 19.841 | 33.113 | ||

| 100 millimeter | 8.251 | 4.873 | 16.340 | 11.820 | 27.778 | 46.296 | 21.459 | 35.714 | ||

| 110 millimeter | 8.881 | 17.730 | 12.723 | 31.250 | 47.170 | 23.041 | 38.168 | |||

| 120 millimeter | 9.506 | 18.797 | 13.624 | 32.895 | 50.000 | 24.631 | 40.984 | |||

| 130 millimeter | 10.101 | 20.000 | 14.535 | 34.722 | 52.632 | 26.316 | 43.478 | |||

| 140 millimeter | 10.707 | 20.833 | 15.432 | 35.461 | 55.556 | 27.933 | 46.296 | |||

| 150 millimeter | 11.312 | 22.222 | 16.340 | 37.594 | 58.824 | 29.412 | 48.544 | |||

| 160 millimeter | 11.905 | 24.272 | 17.241 | 40.984 | 61.728 | 31.056 | 50.505 | |||

| 180 millimeter | 13.123 | 26.882 | 19.011 | 67.568 | 34.247 | 55.556 | ||||

| 170 millimeter | 12.500 | 18.116 | 64.935 | 32.680 | 53.191 | |||||

| 200 millimeter | 14.327 | 29.586 | 20.833 | 49.020 | 73.529 | 37.594 | 60.976 | |||

| 190 millimeter | 13.736 | 19.920 | 70.423 | 35.971 | 58.140 | |||||

| 240 millimeter | 16.722 | 24.510 | 84.746 | 43.860 | 71.429 | |||||

| 220 millimeter | 15.528 | 22.624 | 79.365 | 40.650 | 65.789 | |||||

| 260 millimeter | 17.921 | 26.316 | 90.909 | 47.170 | 76.923 | |||||

| 250 millimeter | 17.301 | 25.381 | 87.719 | 45.455 | 74.627 | |||||

| 300 millimeter | 20.325 | 29.940 | 104.167 | 53.763 | 87.719 | |||||

| 280 millimeter | 19.157 | 28.090 | 98.039 | 50.505 | 81.967 | |||||

| 340 millimeter | 33.557 | 60.241 | 98.039 | |||||||

| 320 millimeter | 31.646 | 56.818 | 92.593 | |||||||

| 380 millimeter | 37.037 | 66.667 | 108.696 | |||||||

| 360 millimeter | 35.211 | 63.291 | 104.167 | |||||||

| 400 millimeter | 39.063 | 69.444 | 113.636 | |||||||

Bolts Coatings |

|||||

|---|---|---|---|---|---|

Zinc Plating |

Hot Dipped Galvanizing |

Chrome Plating |

Teflon Coating |

Oxidized |

|

Epoxy Coating |

Passivation |

Mirror Buffed |

Electro Polished |

||

| China, United Kingdom -UK, South Africa, Chile | ASTM F2281 Boltsing |

| Philippines, UK, Bahrain, United Arab Emirates (UAE) | ASTM F2281 Hex Bolts |

| Malaysia, Philippines, Netherlands | ASTM F2281 Heavy Hex Bolts |

| Sweden, Europe, Oman, Egypt | ASTM F2281 Studs |

| Malaysia, Spain, Germany, Australia | ASTM F2281 Socket Head Cap Screws |

| Singapore, Europe, USA, Malaysia | ASTM F2281 Threaded Rods |

| Japan, Canada, Saudi Arabia (KSA), Italy | ASTM F2281 304 Type I Class A Bolts |

| Colombia, Malaysia, South Africa, Turkey | ASTM F2281 410 Type I Class B Bolts |

| Taiwan, Mexico, Thailand, Malaysia | ASTM F2281 430 Type I Class C Bolts |

| South Korea, Malaysia, Bangladesh, UK | ASTM F2281 309 Type II Bolts |

| Romania, Poland, Kuwait, Singapore | ASTM F2281 660 Type III Class A Bolts |

| Malaysia, Canada, Singapore, Iran | ASTM F2281 600 Type III Class B Bolts |

| Los Alamos -Mexico, Singapore, Finland, Norway | ASTM F2281 601 Type III Class C Bolts |

| NY 12203 (USA), Ellington -United States, Brazil, Russia | ASTM F2281 hex cap screw |

| Dammam -KSA, Singapore, UAE, Hong Kong | ASTM F2281 Bolts |

| Bolts Size | D | B | A (max) | C (min) | E | F Thread Length for Bolts Length |

||

|---|---|---|---|---|---|---|---|---|

| min | max | over 6 | 6 and shorter |

|||||

| 5/16 | 13/64 | 1/2 | 0.324 | 0.665 | 0.01 | 0.03 | 1.125 | 0.875 |

| 1/4 | 11/64 | 3/8 | 0.260 | 0.498 | 0.01 | 0.03 | 1.000 | 0.750 |

| 7/16 | 19/64 | 5/8 | 0.452 | 0.828 | 0.01 | 0.03 | 1.375 | 1.125 |

| 3/8 | 1/4 | 9/16 | 0.388 | 0.747 | 0.01 | 0.03 | 1.250 | 1.000 |

| 5/8 | 27/64 | 15/16 | 0.642 | 1.244 | 0.02 | 0.06 | 1.750 | 1.500 |

| 1/2 | 21/64 | 3/4 | 0.515 | 0.995 | 0.01 | 0.03 | 1.500 | 1.250 |

| 1-1/2 | 1 | 2-1/4 | 1.531 | 2.986 | 0.03 | 0.09 | 3.500 | 3.250 |

| 7/8 | 19/32 | 1-5/16 | 0.895 | 1.742 | 0.02 | 0.06 | 2.250 | 2.000 |

| 3/4 | 1/2 | 1-1/8 | 0.768 | 1.494 | 0.02 | 0.06 | 2.000 | 1.750 |

| 1 | 21/32 | 1-1/2 | 1.022 | 1.991 | 0.03 | 0.09 | 2.500 | 2.250 |

| 1-1/4 | 27/32 | 1-7/8 | 1.277 | 2.489 | 0.03 | 0.09 | 3.000 | 2.750 |

| 1-1/8 | 3/4 | 1-11/16 | 1.149 | 2.239 | 0.03 | 0.09 | 2.750 | 2.500 |

| 1-3/8 | 29/32 | 2-1/16 | 1.404 | 2.738 | 0.03 | 0.09 | 3.250 | 3.000 |

| Alloy Grades | Marking | Condition | Nominal Diameter, in. | Rockwell Hardness | Full-Size Tests | Machined Specimen Tests | |||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength, min, ksi | Tensile Strength, min, ksi | Yield Strength, min, ksi | Tensile Strength, min, ksi | Elongation 4D, min % | |||||

| ASTM F2281 304, 304L Type I, Class A | F1A | A | All diameters | 65 to 95 HRB | 30 | 75 | 30 | 75 | 30 |

| F1B | CWA | 30 | 75 | 30 | 75 | 30 | |||

| F1C | HWA | 30 | 75 | 30 | 75 | 30 | |||

| ASTM F2281 316, 316L Type I, Class A | F1D | A | 30 | 75 | 30 | 75 | 30 | ||

| F1E | CWA | 30 | 75 | 30 | 75 | 30 | |||

| F1F | HWA | 30 | 75 | 30 | 75 | 30 | |||

| ASTM F2281 410, 416 Type I, Class B | F1G | H | Up to 4 diameter | 20 to 30 HRC | 85 | 110 | 85 | 110 | 15 |

| F1H | HT | Up to 4 diameter | 34 to 45 HRC | 120 | 160 | 120 | 160 | 12 | |

| ASTM F2281 431 | F1I | H | All diameters | 25 to 32 HRC | 100 | 125 | 100 | 125 | 15 |

| F1J | HT | 40 to 48 HRC | 140 | 180 | 140 | 180 | 10 | ||

| ASTM F2281 430, 430F Type I, Class C | F1K | A | 65 to 95 HRB | 30 | 55 | 25 | 50 | ... | |

| F1L | CWA | 30 | 55 | 25 | 50 | ... | |||

| F1M | HWA | 30 | 55 | 25 | 50 | ... | |||

| ASTM F2281 309, 310 Type II, Class A | F2A | A | 30 | 75 | 30 | 75 | 30 | ||

| F2B | CWA | 30 | 75 | 30 | 75 | 30 | |||

| F2C | HWA | 30 | 75 | 30 | 75 | 30 | |||

| ASTM F2281 321, 347 Type II, Class A | F2D | A | 30 | 75 | 30 | 75 | 30 | ||

| F2E | CWA | 30 | 75 | 30 | 75 | 20 | |||

| F2F | HWA | 30 | 75 | 30 | 75 | 30 | |||

| ASTM F2281 330 Type II, Class A | F2G | A | 30 | 75 | 30 | 75 | 30 | ||

| F2H | CWA | 30 | 75 | 30 | 75 | 20 | |||

| F2I | HWA | 30 | 75 | 30 | 75 | 30 | |||

| ASTM F2281 600, 601 Type III, Class A | F3A | A | 25 | 80 | 25 | 75 | 35 | ||

| F3B | CWA | 25 | 80 | 25 | 75 | 35 | |||

| F3C | HWA | 25 | 80 | 25 | 75 | 35 | |||

| ASTM F2281 660 Type III, Class B | F3D | Ah4 | 22 to 37 HRC | 85 | 130 | 85 | 130 | 15 | |

| F3E | Ah4 | 85 | 130 | 85 | 130 | 15 | |||

| F3F | Ah4 | 85 | 130 | 85 | 130 | 15 | |||

| ASTM F2281 718 Type III, Class C | F3G | AH4 | 36 to 48 HRC | 150 | 185 | 150 | 180 | 12 | |

| Alloy | Mn | C | S | P | Other | Cr | Si | Cu | Ni | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM F2281 304 Type I, Class A | 2.00 | 0.08 | 0.030 | 0.045 | . . . | 18.0-20.0 | 1.00 | 1.00 | 8.0-10.5 | . . . |

| ASTM F2281 304L Type I, Class A | 2.00 | 0.03 | 0.030 | 0.045 | . . . | 18.0-20.0 | 1.00 | 1.00 | 8.0/12.0 | . . . |

| ASTM F2281 316 Type I, Class A | 2.00 | 0.08 | 0.030 | 0.045 | . . . | 16.0-18.0 | 1.00 | . . . | 10.0-14.0 | 2.00-3.00 |

| ASTM F2281 316L Type I, Class A | 2.00 | 0.03 | 0.030 | 0.045 | . . . | 16.0-18.0 | 1.00 | . . . | 10.0-14.0 | 2.00-3.00 |

| ASTM F2281 410 Type I, Class A | 1.00 | 0.15 | 0.030 | 0.040 | . . . | 11.5-13.5 | 1.00 | . . . | . . . | . . . |

| ASTM F2281 416 Type I, Class A | 1.25 | 0.15 | 0.15 min | 0.060 | . . . | 12.0-14.0 | 1.00 | . . . | . . . | 0.60 |

| ASTM F2281 431 Type I, Class A | 1.00 | 0.20 | 0.030 | 0.040 | . . . | 15.0-17.0 | 1.00 | . . . | 1.25-2.50 | . . . |

| ASTM F2281 430 Type I, Class A | 1.00 | 0.12 | 0.030 | 0.040 | . . . | 16.0-18.0 | 1.00 | . . . | . . . | . . . |

| ASTM F2281 430F Type I, Class A | 1.25 | 0.12 | 0.15 min | 0.060 | . . . | 16.0-18.0 | 1.00 | . . . | . . . | 0.60 |

| ASTM F2281 309 Type II | 2.00 | 0.20 | 0.030 | 0.045 | . . . | 22.0-24.0 | 1.00 | . . . | 12.0-15.0 | . . . |

| ASTM F2281 310 Type II | 2.00 | 0.25 | 0.030 | 0.045 | . . . | 24.0-26.0 | 1.50 | . . . | 19.0-22.0 | . . . |

| ASTM F2281 321 Type II | 2.00 | 0.08 | 0.030 | 0.045 | Ti5 × C min | 17.0-19.0 | 1.00 | . . . | 9.0-12.0 | . . . |

| ASTM F2281 330 Type II | 2.00 | 0.08 | 0.030 | 0.030 | . . . | 17.0-20.0 | 0.75-1.50 | . . . | 34.0-37.0 | . . . |

| ASTM F2281 347 Type II | 2.00 | 0.08 | 0.030 | 0.045 | Cb + Ta 10 × C min | 17.0-19.0 | 1.00 | . . . | 9.0-13.0 | . . . |

| ASTM F2281 600 Type III, Class A | 1.00 | 0.10 | 0.015 | . . . | Fe 6.0/10.0 | 14.0-17.0 | 0.50 | 0.50 | 72.0 min | . . . |

| ASTM F2281 601 Type III, Class A | 1.00 | 0.10 | 0.015 | . . . | Al 1.0/1.7 Fe remainder |

21.0-25.0 | 0.50 | 1.00 | 58.0-63.0 | . . . |

| ASTM F2281 660 Type III, Class B | 2.00 | 0.08 | 0.030 | 0.040 | Ti 1.90-2.30 V 0.10-0.50 Al 0.35 max B 0.003-0.010 Fe remainder |

13.5-16.0 | 1.00 | . . . | 24.0-27.0 | 1.00-1.75 |

| ASTM F2281 718 Type III, Class C | 0.35 | 0.08 | 0.015 | 0.015 | Ti 0.65-1.15 Co 1.00 max Al 0.20-0.80 B 0.006 max Cb + Ta 4.75-5.50 Fe remainder |

17.0-21.0 | 0.35 | 0.30 | 50.0-55.0 | 2.80-3.30 |

| Alloy Grade | Safe Scaling Temperature at Continuous Service Application | Safe Scaling Temperature at Continuous Service Application |

|---|---|---|

| ASTM F2281 316/316L Type I, Class A | ... | ... |

| ASTM F2281 410/416 Type I, Class B | ... | 1200°F (649°C) |

| ASTM F2281 660 Type III, Class B | ... | 1300°F (704°C) |

| ASTM F2281 304/304L Type I, Class A | ... | 1600°F (871°C) |

| ASTM F2281 430/430F Type I, Class C | ... | 1500°F (816°C) |

| ASTM F2281 601 Type III, Class A | ... | 2000°F (1095°C) |

| ASTM F2281 431 Type I, Class B | ... | 1300°F (704°C) |

| ASTM F2281 310 Type II | 2000°F (1093°C) | 2100°F (1149°C) |

| ASTM F2281 309 Type II | 1850°F (1010°C) | 2000°F (1093°C) |

| ASTM F2281 330 Type II | 2200°F (1204°C) | 2200°F (1204°C) |

| ASTM F2281 321 Type II | 1650°F (899°C) | 1600°F (871°C) |

| ASTM F2281 600 Type III, Class A | ... | 1800°F (980°C) |

| ASTM F2281 347 Type II | 1650°F (871°C) | 1600°F (871°C) |

| Class | Type | Condition |

|---|---|---|

| B | I | H, HT |

| A | I | A, CWA, HWA |

| ... | II | A, CWA, HWA |

| C | I | A, CWA, HWA |

| B | III | Ah4, Ah4 or Ah4 |

| A | III | A, CWA, HWA |

| C | III | AH4 |

| Additional Tests | S2 |

|---|---|

| Shipment Lot Testing | S1 |

| High Temperature Tests | S8 |

| Heat Control | S4 |

| Source Inspection | S3 |

| Corrosion Resistance Tests | S6 |

| Permeability | S5 |

| Passivation | S7 |