A superalloy with an iron base and nickel content is known as Grade 660 or A286. However, due to the alloy of A453 Gr 660 contains a high concentration of nickel, the metal is sometimes considered to be a nickel alloy rather than a stainless steel one. In addition to having high strength, the UNS 66286 Threaded Rod further has remarkable corrosion resistance qualities up to 1300°F. Nevertheless, when aqueous media are present, the ASTM A453 Gr 660 Stainless Steel Bolt is known to exhibit moderate corrosion resistance properties.

It is possible to age-harden an austenitic alloy to increase its strength.a286 stainless steel bolts material. The classification of this alloy is a high strength one, yet, the applications of the A453 Gr 660 Class A/B/C/D Stud Boltsis appropriate for a low-pressure application when the application's temperature is high. The ideal application of ASTM A453 Grade 660 Stud Boltsas fasteners is frequently observed in pressure tanks or valve flanges. This particular standard addresses how different elements are included in the chemical makeup of the A286 Stainless Steel Fasteners. Besides its chemistry, like most other specifications, the ASTM A453 Gr 660 Cl.A Stud bolt is required to be put through various tests including tension test, hardness test as well as a stress-rupture test.

And the specification also has prerequisites that the ASTM A453 Grade 660 bolts elongation, reduction of area, Brinell and Rockwell hardness, yield and tensile strength, among others, must all be met. The specification also discusses the requirements for Hardening and Solution Treatment forSA 453 Grade 660 Material with details in all classes.

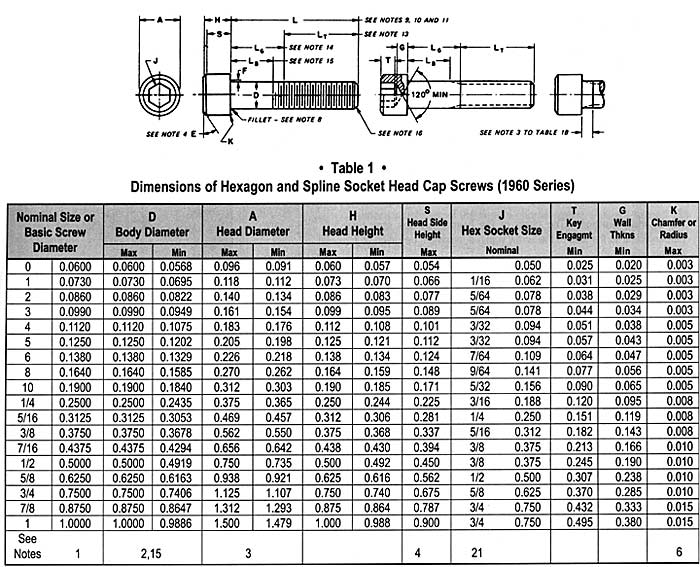

Dimensions |

ASME B18.2.1, B18.3 |

|---|---|

Melt Origin |

South America/East Europe/JapanKorea/ |

Product Origin |

Made in India |

Threads Configuration |

ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

Certification |

Dual Certified As per ASTM & ASME Codes |

Additional Certifications |

PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

Mandatory Requirements |

Free from Mercury & Radioactive Contamination |

Additional Requirements |

NACE MR0103 / MR0175 / ISO 15156 Compliance |

| Description | Per Unit (INR) | Price in USD | Price in EURO |

|---|---|---|---|

| Stainess Steel Bolts & Nuts - Stud Boltwith Nut, 7/8 X 150 Mm A453 Gr 660b, Astm A194 Gr8 | 996 | 13.55 | 11.06 |

| Full Thread Stud+2 Heavy Hex Nuts/astma453 Gr. 660 Cl G/buffed7/8 X 150 Mm | 1,062 | 14.45 | 11.79 |

| Full Thread Stud+2 Heavy Hex Nuts/astma453 Gr. 660 Cl G/buffed7/8 X 170 Mm | 1,062 | 14.45 | 11.79 |

| 66a-nuts/bolts/screws/washer Made Of Alloy Steel Including Stainless Steel Stud Bolt With 2 Hex Nuts, Gr-660 7/8 X 165mm | 1,147 | 15.60 | 12.73 |

| 66a-nuts/bolts/screws/washer Made Of Alloy Steel Including Stainless Steel Stud Bolt With 2 Hex Nuts Gr-660 7/8 X140mm L | 1,063 | 14.46 | 11.80 |

| Stainless Steel Stud Bolt With 2 Heavy Hex Nuts To Asme Sa 453 Gr. 660b,8un Fullthread Size:1-7/8-8un X 935 Mm Length | 99,058 | 1347.38 | 1099.81 |

| Sa 453 Gr. 660b Stud Bolt With 2 Heavy Hex Nut-7/8 Unc X 140mm Lg. | 1,493 | 20.31 | 16.58 |

| Grade A453 660b- Stud Volt & 2 Nuts, 7/8 Unc X 235 Mm | 570 | 7.75 | 6.33 |

| Grade A453 660b- Stud Volt & 2 Nuts, 7/8 Unc X 310 Mm | 751 | 10.21 | 8.34 |

| Astm A453 Gr. 660a Ptfe Coated Stud Bolt With 2 Hex Nut 1 8un 2a X 7-1/4 Long(212.200/236.200 Kg) | 1,414 | 19.23 | 15.70 |

| 7/8 X 155mm Stud Bolt C/w 2 Heavy Hex Nuts, A453 Gr.660 Class A | 2,373 | 32.28 | 26.35 |

| A 453-660 Stud Bolt With 2 Nut 7/8-8 Unc X 240 Mm Lg, 66 A-nuts/bolts/screws/washer Made Of Alloysteel Including Stainless | 1,611 | 21.91 | 17.89 |

| Property | Description |

|---|---|

| Class A | ... |

| Class B | ... |

| Class C | ... |

| Class D | ... |

| Grade | Class | Solutiona Treatment | Hardening Treatment |

|---|---|---|---|

| 660 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool | |

| C | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and oil quench | 1425 +/- 25 °F [775 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |

| D | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench OR | 1325 +/- 25 °F [720 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool if neccessary to achieve properties, second age : 1200 +/- 25 °F [650 +/- 14 °C] hold 16h, air cool | |

| 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | |||

| 651 | A | hot-cold worked at 1200 °F[650] min with 15% min reduction in cross sectional area, stress-relief anneal at 1200 °F [650 °C] min or 4h, min | |

| B | hot-cold worked at 1200 °F[650] min with 15% min reduction in cross sectional area, stress-relief anneal at 1350 °F [730 °C] min or 4h, min | ||

| 662 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 1950 +/- 25 °F [1065 +/-14 °C], hold 2 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 665 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 2000 +/- 25 °F [1095 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 668 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| Product | DIN | ISO | ASME | UNI | |

|---|---|---|---|---|---|

| Imperial | Metric | ||||

| Studs | 976 | -- | B18.31.2 | B18.31.1M | 6610 |

| Hex Bolts | 931 | 4014 | B18.2.1 | B18.2.3.5M | 5737 |

| Heavy Hex Bolts | 6914 | 7412 | B18.2.1 | B18.2.3.7M | 5712 |

| Hex Cap Screws | 933 | 4017 | B18.2.1 | B18.2.3.1M | 5739 |

| Socket Head Cap Screws | 912 | 4762 | B18.3 | B18.3.1M | 5931 |

| Set Screws | 916 | 4029 | B18.3 | B18.3.1M | 5929 |

| Countersunk Screws | 7991 | 10642 | B18.3 | B18.3.1M | 5933 |

| Hex Nuts | 934 | 4032 | B18.2.2 | B18.2.4.1M | 5588 |

| Heavy Hex Nuts | 6915 | 4775 | B18.2.2 | B18.2.4.6M | 5713 |

Diameter (D) |

Body Diameter (D) |

Across the Flats (F) |

Across the Corners © |

Head Height (H) |

Thread Lengths (T) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

MAX |

MIN |

MAX |

MIN |

MAX |

MIN |

MAX |

MIN |

< 6” |

> 6” |

|

1/2 |

0.515 |

0.482 |

0.875 |

0.85 |

1.01 |

0.969 |

0.364 |

0.302 |

1.25 |

1.5 |

5/8 |

0.642 |

0.605 |

1.062 |

1.031 |

1.227 |

1.175 |

0.444 |

0.378 |

1.5 |

1.75 |

3/4 |

0.768 |

0.729 |

1.25 |

1.212 |

1.443 |

1.383 |

0.524 |

0.455 |

1.75 |

2 |

7/8 |

0.895 |

0.852 |

1.438 |

1.394 |

1.66 |

1.589 |

0.604 |

0.531 |

2 |

2.25 |

1 |

1.022 |

0.976 |

1.625 |

1.575 |

1.876 |

1.796 |

0.7 |

0.591 |

2.25 |

2.5 |

1 1/8 |

1.149 |

1.098 |

1.812 |

1.756 |

2.093 |

2.002 |

0.78 |

0.658 |

2.5 |

2.75 |

1 1/4 |

1.277 |

1.223 |

2 |

1.938 |

2.309 |

2.209 |

0.876 |

0.749 |

2.75 |

3 |

1 3/8 |

1.404 |

1.345 |

2.188 |

2.119 |

2.526 |

2.416 |

0.94 |

0.81 |

3 |

3.25 |

1 1/2 |

1.531 |

1.47 |

2.375 |

2.3 |

2.742 |

2.622 |

1.036 |

0.902 |

3.25 |

3.5 |

1 3/4 |

1.785 |

1.716 |

2.75 |

2.662 |

3.175 |

3.035 |

1.196 |

1.054 |

3.75 |

4 |

2 |

2.039 |

1.964 |

3.125 |

3.025 |

3.608 |

3.449 |

1.388 |

1.175 |

4.25 |

4.5 |

2 1/4 |

2.305 |

2.214 |

3.5 |

3.388 |

4.041 |

3.862 |

1.548 |

1.327 |

4.75 |

5 |

2 1/2 |

2.559 |

2.461 |

3.875 |

3.75 |

4.474 |

4.275 |

1.708 |

1.479 |

5.25 |

5.5 |

2 3/4 |

2.827 |

2.711 |

4.25 |

4.112 |

4.907 |

4.688 |

1.869 |

1.632 |

5.75 |

6 |

3 |

3.081 |

2.961 |

4.625 |

4.475 |

5.34 |

5.102 |

2.06 |

1.815 |

6.25 |

6. |

NOMINAL SIZE (D) |

BODY DIAMETER |

HEAD THICKNESS |

ACROSS THE FLATS |

ACROSS BOLTS CORNERS |

||||

|---|---|---|---|---|---|---|---|---|

D (MAX) |

D (MIN) |

H (MAX) |

H (MIN) |

F (MAX) |

F (MIN) |

C (MAX) |

C (MIN) |

|

m10 |

10.00 |

9.78 |

6.63 |

6.17 |

17.00 |

15.73 |

18.48 |

17.77 |

m12 |

12.00 |

11.73 |

7.76 |

4.24 |

19.00 |

17.73 |

20.78 |

20.03 |

m14 |

14.00 |

13.73 |

9.09 |

8.51 |

22.00 |

20.67 |

24.25 |

23.35 |

m16 |

16.00 |

15.73 |

10.32 |

9.68 |

24.00 |

23.67 |

27.71 |

26.75 |

m20 |

20.00 |

19.67 |

12.88 |

12.12 |

30.00 |

29.16 |

34.64 |

32.95 |

m24 |

24.00 |

23.67 |

15.44 |

14.56 |

36.00 |

35.00 |

41.57 |

39.55 |

m30 |

30.00 |

29.67 |

19.48 |

17.92 |

46.00 |

45.00 |

53.12 |

50.85 |

m36 |

36.00 |

35.61 |

23.38 |

21.63 |

55.00 |

53.80 |

63.51 |

60.79 |

m42 |

42.00 |

41.38 |

26.97 |

25.03 |

65.00 |

62.90 |

75.06 |

71.71 |

m48 |

48.00 |

47.38 |

31.07 |

28.93 |

75.00 |

72.60 |

86.60 |

82.76 |

m56 |

56.00 |

55.26 |

36.2 |

33.80 |

85.00 |

82.20 |

98.15 |

93.71 |

m64 |

64.00 |

63.26 |

41.32 |

38.68 |

95.00 |

91.80 |

109.70 |

104.65 |

m72 |

72.00 |

71.26 |

46.45 |

43.55 |

105.00 |

101.40 |

121.24 |

115.60 |

m80 |

80.00 |

79.26 |

51.58 |

48.42 |

115.00 |

111.00 |

132.72 |

126.54 |

m90 |

90.00 |

89.13 |

57.74 |

54.26 |

130.00 |

125.50 |

150.11 |

143.07 |

m100 |

90.00 |

99.13 |

63.9 |

60.10 |

145.00 |

140.00 |

167.43 |

159.60 |

| Dia. | Coarse | Fine |

|---|---|---|

| M10 | 1,5 | 1,25 |

| M12 | 1,75 | 1,5 |

| M14 | 2 | 1 |

| M16 | 2 | 1 |

| M18 | 2,5 | 1 |

| M20 | 2,5 | 1,25 |

| M22 | 2,5 | 1,25 |

| M24 | 3 | 1,25 |

| M27 | 3 | 1,5 |

| M30 | 3,5 | 1,5 |

| M33 | 3,5 | 2 |

| M36 | 4 | 3 |

| M39 | 4 | 3 |

| M42 | 4,5 | 3 |

| M45 | 4,5 | 3 |

| M48 | 5 | 3 |

| M52 | 5 | 3 |

| M56 | 5,5 | 4 |

| M64 | 6 | 4 |

Flat Washer Metric DIN 125A 125

| D | d1 | d2 | h |

|---|---|---|---|

| M1 | 1.1000 | 3.0000 | 0.3000 |

| M1.2 | 1.3000 | 3.5000 | 0.3000 |

| M1.4 | 1.5000 | 4.0000 | 0.3000 |

| M1.6 | 1.7000 | 4.0000 | 0.3000 |

| M1.7 | 1.8000 | 4.5000 | 0.3000 |

| M2 | 2.2000 | 5.0000 | 0.3000 |

| M2.3 | 2.5000 | 6.0000 | 0.5000 |

| M2.5 | 2.7000 | 6.0000 | 0.5000 |

| M2.6 | 2.8000 | 7.0000 | 0.5000 |

| M3 | 3.2000 | 7.0000 | 0.5000 |

| M3.5 | 3.7000 | 8.0000 | 0.5000 |

| M4 | 4.3000 | 9.0000 | 0.8000 |

| M5 | 5.3000 | 10.0000 | 1.0000 |

| M6 | 6.4000 | 12.0000 | 1.6000 |

| M7 | 7.4000 | 14.0000 | 1.6000 |

| M8 | 8.4000 | 16.0000 | 1.6000 |

| M10 | 10.5000 | 20.0000 | 2.0000 |

| M12 | 13.0000 | 24.0000 | 2.5000 |

| M14 | 15.0000 | 28.0000 | 2.5000 |

| M16 | 17.0000 | 30.0000 | 3.0000 |

| M18 | 19.0000 | 34.0000 | 3.0000 |

| M20 | 21.0000 | 37.0000 | 3.0000 |

| M22 | 23.0000 | 39.0000 | 3.0000 |

| M24 | 25.0000 | 44.0000 | 4.0000 |

| M27 | 28.0000 | 50.0000 | 4.0000 |

| M30 | 31.0000 | 56.0000 | 4.0000 |

| M33 | 34.0000 | 60.0000 | 5.0000 |

| M36 | 37.0000 | 6.0000 | 5.0000 |

| M39 | 40.0000 | 72.0000 | 6.0000 |

| M42 | 43.0000 | 78.0000 | 7.0000 |

| M45 | 46.0000 | 85.0000 | 7.0000 |

| M48 | 50.0000 | 92.0000 | 8.0000 |

| M52 | 54.0000 | 98.0000 | 8.0000 |

| M55 | 57.0000 | 105.0000 | 9.0000 |

| M56 | 58.0000 | 105.0000 | 9.0000 |

| M58 | 60.0000 | 110.0000 | 9.0000 |

| M60 | 62.0000 | 110.0000 | 9.0000 |

| M64 | 66.0000 | 115.0000 | 9.0000 |

| M68 | 70.0000 | 120.0000 | 10.0000 |

| M72 | 74.0000 | 125.0000 | 10.0000 |

| M76 | 78.0000 | 135.0000 | 10.0000 |

| M80 | 82.0000 | 140.0000 | 12.0000 |

| M85 | 87.0000 | 145.0000 | 12.0000 |

| M90 | 93.0000 | 160.0000 | 12.0000 |

| M95 | 98.0000 | 165.0000 | 12.0000 |

| M100 | 104.0000 | 175.0000 | 14.0000 |

| M105 | 109.0000 | 180.0000 | 14.0000 |

| M110 | 114.0000 | 185.0000 | 14.0000 |

| M115 | 119.0000 | 200.0000 | 14.0000 |

| M120 | 124.0000 | 210.0000 | 16.0000 |

| M125 | 129.0000 | 220.0000 | 16.0000 |

| M130 | 134.0000 | 230.0000 | 16.0000 |

| M135 | 139.0000 | 230.0000 | 16.0000 |

| M140 | 144.0000 | 240.0000 | 18.0000 |

| M145 | 149.0000 | 250.0000 | 18.0000 |

| M150 | 155.0000 | 250.0000 | 18.0000 |

| M160 | 165.0000 | 250.0000 | 18.0000 |

| Grade | Class | Test Temperature | Stress, Min | Time to Rupture | Elongation | |

|---|---|---|---|---|---|---|

| Deg F [ Deg C ] | Ksi | Mpa | Min, h* | Min % | ||

| 660 | A, B & C | 1200 [650] | 56 | 385 | 100 | 5 |

| 651 | A & B | 1200 [650] | 40 | 275 | 100 | 5 |

| 662 | A & B | 1200 [650] | 55 | 380 | 100 | 5 |

| 665 | A | 1200 [650] | 75 | 515 | 100 | 3 |

| B | 1200 [650] | 70 | 485 | 100 | 5 | |

Stud Metal End =1.1/2 D 4H Metric Coarse BS 4439

| d | b | c l<125 | c l<125<200 | c l 200> |

|---|---|---|---|---|

| M3 | 5.0000 | 12.0000 | 18.0000 | |

| M4 | 6.0000 | 14.0000 | 20.0000 | |

| M5 | 8.0000 | 16.0000 | 22.0000 | |

| M6 | 9.0000 | 18.0000 | 24.0000 | 37.0000 |

| M7 | 11.0000 | 20.0000 | 26.0000 | 39.0000 |

| M8 | 12.0000 | 22.0000 | 28.0000 | 41.0000 |

| M10 | 15.0000 | 26.0000 | 32.0000 | 45.0000 |

| M12 | 18.0000 | 30.0000 | 36.0000 | 49.0000 |

| M14 | 21.0000 | 34.0000 | 40.0000 | 53.0000 |

| M16 | 24.0000 | 38.0000 | 44.0000 | 57.0000 |

| M18 | 27.0000 | 42.0000 | 48.0000 | 61.0000 |

| M20 | 30.0000 | 46.0000 | 52.0000 | 65.0000 |

| M22 | 33.0000 | 50.0000 | 56.0000 | 69.0000 |

| M24 | 36.0000 | 54.0000 | 60.0000 | 73.0000 |

| M27 | 41.0000 | 60.0000 | 66.0000 | 79.0000 |

| M30 | 45.0000 | 66.0000 | 72.0000 | 85.0000 |

| M33 | 50.0000 | 72.0000 | 78.0000 | 91.0000 |

| M36 | 54.0000 | 78.0000 | 84.0000 | 97.0000 |

| Grade | Class A | Class B | Class C | Class D |

|---|---|---|---|---|

| Grade 660 | 660A | 660B | 660C | 660D NR |

| D | D | s | s max | s min | e max | e min | m | m max | m min |

|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 0.2500 | 1/2" | 0.5000 | 0.4880 | 0.5770 | 0.5560 | 15/64" | 0.2500 | 0.2180 |

| 5/16" | 0.3125 | 9/16" | 0.5620 | 0.5460 | 0.6500 | 0.6220 | 19/64" | 0.3140 | 0.2800 |

| 3/8" | 0.3750 | 11/16" | 0.6880 | 0.6690 | 0.7940 | 0.7630 | 23/64" | 0.3770 | 0.3410 |

| 7/16" | 0.4375 | 3/4" | 0.7500 | 0.7280 | 0.8660 | 0.8300 | 27/64" | 0.4410 | 0.4030 |

| 1/2" | 0.5000 | 7/8" | 0.8750 | 0.8500 | 1.0100 | 0.9690 | 31/64" | 0.5040 | 0.4640 |

| 9/16" | 0.5625 | 15/16" | 0.9380 | 0.9090 | 1.0830 | 1.0370 | 35/64" | 0.5680 | 0.5260 |

| 5/8" | 0.6250 | 1.1/16" | 1.0620 | 1.0310 | 1.2270 | 1.1750 | 39/64" | 0.6310 | 0.5870 |

| 3/4" | 0.7500 | 1.1/4" | 1.2500 | 1.2120 | 1.4430 | 1.3820 | 47/64" | 0.7580 | 0.7100 |

| 7/8" | 0.8750 | 1.7/16" | 1.4380 | 1.3940 | 1.6600 | 1.5890 | 55/64" | 0.8850 | 0.8330 |

| 1" | 1.0000 | 1.5/8" | 1.6250 | 1.5750 | 1.8760 | 1.7960 | 63/64" | 1.0120 | 0.9560 |

| 1.1/8" | 1.1250 | 1.13/16" | 1.8120 | 1.7560 | 2.0930 | 2.0020 | 1.7/64" | 1.1390 | 1.0790 |

| 1.1/4" | 1.2500 | 2" | 2.0000 | 1.9380 | 2.3090 | 2.2090 | 1.7/32" | 1.2510 | 1.1870 |

| 1.3/8" | 1.3750 | 2.3/16" | 2.1880 | 2.1190 | 2.5260 | 2.4160 | 1.11/32" | 1.3780 | 1.3100 |

| 1.1/2" | 1.5000 | 2.3/8" | 2.3750 | 2.3000 | 2.7420 | 2.6220 | 1.15/32" | 1.5050 | 1.4330 |

| 1.5/8" | 1.6250 | 2.9/16" | 2.5620 | 2.4810 | 2.9590 | 2.8280 | 1.19/32" | 1.6320 | 1.5560 |

| 1.3/4" | 1.7500 | 2.3/4" | 2.7500 | 2.6620 | 3.1750 | 3.0350 | 1.23/32" | 1.7590 | 1.6790 |

| 1.7/8" | 1.8750 | 2.15/16" | 2.9380 | 2.8440 | 3.3920 | 3.2420 | 1.27/32" | 1.8860 | 1.8020 |

| 2" | 2.0000 | 3.1/8" | 3.1250 | 3.0250 | 3.6080 | 3.4490 | 1.31/32" | 2.0130 | 1.9250 |

| 2.1/4" | 2.2500 | 3.1/2" | 3.5000 | 3.3880 | 4.0410 | 3.8620 | 2.13/64" | 2.2510 | 2.1550 |

| 2.1/2" | 2.5000 | 3.7/8" | 3.8750 | 3.7500 | 4.4740 | 4.2750 | 2.29/64" | 2.5050 | 2.4010 |

| 2.3/4" | 2.7500 | 4.1/4" | 4.2500 | 4.1120 | 4.9070 | 4.6880 | 2.45/64" | 2.7590 | 2.6470 |

| 3" | 3.0000 | 4.5/8" | 4.6250 | 4.4750 | 5.3400 | 5.1020 | 2.61/64" | 3.0130 | 2.8930 |

| 3.1/4" | 3.2500 | 5" | 5.0000 | 4.8380 | 5.7740 | 5.5150 | 3.3/16" | 3.2520 | 3.1240 |

| 3.1/5" | 3.5000 | 5.3/8" | 5.3750 | 5.2000 | 6.2070 | 5.9280 | 3.7/16" | 3.5060 | 3.3700 |

| 3.3/4" | 3.7500 | 5.3/4" | 5.7500 | 5.5620 | 6.6400 | 6.3410 | 3.11/16" | 3.7600 | 3.6160 |

| 4" | 4.0000 | 6.1/8" | 6.1250 | 5.9250 | 7.0730 | 6.7550 | 3.15/16" | 4.0140 | 3.8620 |

| Hexagon Bolts / Set Screws | Stud Bolts | Hexagon Nuts | Socket Cap screws |

|---|---|---|---|

| DIN 931 | BS4882 | DIN 934 | DIN 912 |

| DIN 933 | DIN 976 | BS 1768 | DIN 6912 |

| BS 1768 | BS 1769 | DIN 7984 | |

| UNI 5731 | BS 1083 | ANSI B18.3 | |

| UNI 5739 | BS 3692 | ISO 4762 | |

| ISO 4014 | ISO 4032 | UNI 5931 | |

| ISO 4017 | ISO 4033 | BS 2470 | |

| BS 1769 | ANSI B18.2.2 | BS 4168 | |

| BS 3692 | |||

| ANSI B18.2.1 |

| Socket & Slotted Set Screws | Socket & Slotted Countersunk Screws | Studs | Washers |

|---|---|---|---|

| DIN 913 | DIN 963 | DIN 938 | DIN 125 |

| DIN 914 | DIN 7991 | DIN 939 | DIN 9021 |

| DIN 915 | BS 4168 | DIN 2510 | BS 4320 |

| DIN 916 | BS 1981 | BS 4439 | BS 3410 |

| DIN 551 | BS 483 | BS 2693 | |

| DIN 553 | BS 2470 | Spring Washers | |

| DIN 438 | DIN 127 | ||

| BS 4168 | BS 4464 | ||

| BS 1802 |

| ELEMENT | Grade 660 | Grade 651 | Grade 662 | Grade 665 | Grade 668 |

|---|---|---|---|---|---|

| % | % | % | % | % | |

| Carbon | 0.08 max | 0.28-0.35 | 0.08 max | 0.08 max | 0.08 max |

| Manganese | 2.00 max | 0.75-1.5 | 0.40-1.00 | 1.25-2.00 | 2.00 max |

| Phosphorus, max | 0.040 max | 0.040 max | 0.040 max | 0.040 max | 0.040 max |

| Sulfur, max | 0.030 max | 0.030 max | 0.030 max | 0.030 max | 0.030 max |

| Silicon | 1.00 max | 0.30-0.80 | 0.40-1.00 | 0.1-0.80 | 1.00 max |

| Nickel | 24.0-27.0 | 8.0-11.0 | 24.0-28.0 | 24.0-28.0 | 17.5-21.5 |

| Chromium | 13.5-16.0 | 18.0-21.0 | 12.0-15.0 | 12.0-15.0 | 13.5-16.0 |

| Molybdenum | 1.00-1.50 | 1.00-1.75 | 2.0-3.50 | 1.25-2.25 | 1.50 max |

| Tungsten | ... | 1.00-1.75 | ... | ... | ... |

| Titanium | 1.9-2.35 | 0.1-0.35 | 1.80-2.10 | 2.70-3.30 | 2.20-2.80 |

| Columbium * | ... | 0.25-0.6 | ... | ... | ... |

| Aluminum | 0.35 max | 0.35 max | 0.25 max | 0.50 max | |

| Vanadium | 0.10-0.50 | ... | ... | 0.50 max | |

| Boron | 0.001-0.010 | 0.001-0.010 | 0.01-0.07 | 0.001-0.010 | |

| Copper | 0.50 max | 0.50 max | 0.25 max | ... |

| Size | Class | Tensile, Mpa | Yield, Mpa | Elong. %, min | RA %, min |

|---|---|---|---|---|---|

| Grade 660 | A, B , & C | 895 min | 585 min | 15 | 18 |

| D | 895 min | 725 min | 15 | 18 | |

| Grade 651 | A | 690 min | 485 min | 18 | 35 |

| 415 min | |||||

| B | 655 min | 415 min | 18 | 35 | |

| 345 min | |||||

| Grade 662 | A | 895 min | 585 min | 15 | 18 |

| B | 860 min | 550 min | 15 | 18 | |

| Grade 665 | A | 1170 min | 830 min | 12 | 15 |

| B | 1070 min | 830 min | 12 | 15 | |

| Grade 665 | A & B | 895 min | 858 min | 15 | 18 |

| Werkstoff Numbers |

|

| European Specifications |

|

| ASTM Specifications |

|

| ASME Specifications |

|

| GE Specifications |

|

| AMS Specifications |

|

| Other Specifications & Compliance |

|

ASTM A453 GR 660 Heavy Hex Bolts |

Grade 660 Shoulder Bolt |

ASTM A453 GR 660 Class A Anchor Bolt |

ASTM A453 660 Stud Bolts |

ASTM A453 Eye Bolt |

ASTM A453 GR 660 Class B Stud Bolt |

Grade 660 Step Bolt |

Stainless Steel GR 660 Studs |

ISO Approved ASTM A453 U Bolts |

SS Grade 660 Plow Bolt |

Class D Nuts |

GR 660 Grub Screw |

Stainless Steel GR 660 Threaded Rod |

ASTM A453 J Bolt |