Gas turbines, commonly referred to as combustion turbines, are one application for Inconel 718 tubing. An ongoing device that uses an internal combustion engine is a gas turbine.

A major roadblock during the construction of a turbine is selecting an appropriate material that aids to combat creep. In this instance, Inconel 718 is an ideal metal, which not only offers good tensile, but also good fatigue, along with higher creep, and rupture strength. Moreover, creep occurring in these turbines is a result of both high stress and elevated temperatures. Since Inconel 718 is a high strength alloy, the UNS N07718 tube is able to withstand temperature as high as about 1300°F.

Choosing the right material to combat creep is a big challenge when building a turbine. In this case, Inconel 718 is the best metal since it offers high tensile strength as well as high fatigue strength, higher creep strength, and high rupture strength. Tremendous temperatures and high stress both contribute to the creep of these turbines. Because Inconel 718 is a high strength alloy, it can withstand temperatures as high as about 1300°F in the UNS N07718 tube.

The major requirement for applications involving fluid lines and components, where the AMS 5589 Alloy 718 seamless pipe is ideally suited, is resistance to stress-rupture up to a temperature of 1300°F. Additionally, Alloy 718 seamless tubing that meets AMS 5589 specifications provides good oxidation resistance up to 1800°F.

Compare Inconel 718 tube price with inconel 625 tube price list

ASME and ASTM designation |

ASTM B163/ ASME SB 163 |

Inventory Size Ranges |

15" to 150″NB Inch |

| Dimension Table | ASME, ASTM and API |

| Size table of Seamless Pipes | Wall Thikness: 0.5mm to 20mm Size: 4mm to 219mm |

| Size range of Welded Pipes | 5.0 to 1219.2 mm |

| EFW Pipes available Size | 5.0 to 1219.2 mm |

| Popular For | Inconel 718 Large Diameter Pipe |

| Pipe Schedule as per ASME B36.10M or B36.19M | SCH160 STD, SCH10, SCH40, SCH80, SCH5, |

| List of pipe types | Welded / ERW / Seamless / LSAW/ Fabricated Pipes |

| Most Common Pipe Form | Hydraulic, Round Form Etc |

| Pipe length type | Double Random, Cut Length & Single Random |

| Pipe End Type Abbreviations | Beveled End, Plain End, Theaded |

Because Inconel 718 Tubing is durable up to 1300°F, it is used in aerospace engines. Alloy 718 manufacturers typically create seamless pipes and tubes, however seam welding of coils can be provided upon request.

Alloy718 seamless Pipe

Size:15" to 150″NB Inch

Wall Thikness: 0.5 to 20mm

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| 718 | 2.4668 | N07718 | NCF 718 | – | – | – | – |

| Grade | Elongation | Density | Tensile Strength | Melting Point | Strength of Yield (0.2%Offset) |

|---|---|---|---|---|---|

| 718 | 45 % | 8.2 g/cm3 | Psi – 1,35,000 , MPa – 930 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 482 |

The alloy 718 is a precipitation-hardenable nickel-chromium alloy. At high temperatures of around 700 °C, it possesses extremely high creep rupture strengths. It is an alloy with high strength and excellent corrosion resistance. It may be easily manufactured as well as toughened. It possesses very high minimum yield strength and tensile strength values of 980MPa and 1100MPa, respectively. Therefore, the material can be used in cryogenic applications, aerospace and aviation, as well as other high temperature services. The alloy 718 is utilised in aerospace components and in oilfield applications due to the high temperatures and highly corrosive composition that may be present.

| Nickel Alloy 718 Electropolished Tubing | ASME SB 163 Inconel 718 Dom Tube |

| Inconel Alloy 718 Hydraulic Tubing | ASTM B163 Inconel 718 Condenser Tubing |

| 2.4668 Alloy 718 ERW Tubing | Cold Drawn Inconel 718 Seamless Tube |

| ASME SB 163 UNS N07718 Inconel Round Tubing | 718 Inconel Finned Tubes |

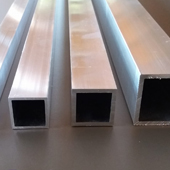

| Inconel 718 Square Tubes | Inconel 718 Alloy Hollow Tubes |

| Inconel 718 Seamless Tubes | UNS N07718 Inconel 718 Coil Tubing |

| Inconel 718 UNS N07718 Instrument Tubing | ASTM B163 Alloy 718 Polish Tubing |

| 2.4668 Inconel 718 Welded Tubing | Thin Wall Inconel 718 Din 2.4668 Tubing |

| ASTM B163 Inconel 718 Square Tubing | Nickel Alloy 718 Sanitary Tube |

| Alloy 718 High Pressure Tubing | ASME SB 163 UNS N07718 Inconel Elliptical and Oval Tube |

| ASTM B163 UNS N07718 Inconel Small Diameter Tubing | 12mm 2.4668 Alloy 718 Tubes |

| ASTM B163 Alloy 718 Rectangular Tubing | 718 Inconel Electropolish Tubes |

| UNS N07718 Inconel 718 Capillary Tubes | Inconel 718 UNS N07718 Heat exchanger Tube |

| Inconel 718 Din 2.4668 Exhaust Tubing | 1 inch ASTM B163 UNS N07718 Inconel Tube |

| ASME SB 163 Inconel 718 EFW Tubing | 2.4668 Inconel 718 Triangle Tubing |

| Inconel 718 Alloy Gas Tubes | Inconel Alloy 718 Coiled Tubing |

| 718 Inconel Round Tubes | Re Drawn UNS N07718 Inconel 718 Tube |

| Inconel 718 Alloy ERW Tubes | High Pressure 2.4668 Inconel 718 Tubing |

| Alloy 718 Tube Bends | Inconel Alloy 718 Instrumentation Tubing |

| GAUGE | THICKNESS RANGE (INCH) | TYPICAL VALUE (INCH) |

|---|---|---|

| 22 | 0.025 - 0.029 | 0.028 |

| 20 | 0.031 - 0.035 | 0.035 |

| 19 | 0.038 - 0.042 | 0.042 |

| 18 | 0.044 - 0.049 | 0.049 |

| 17 | 0.053 - 0.058 | 0.058 |

| 16 | 0.060 - 0.065 | 0.065 |

| 15 | 0.066 - 0.074 | 0.072 |

| 14 | 0.075 - 0.085 | 0.083 |

| 13 | 0.087 - 0.097 | 0.095 |

| 12 | 0.101 - 0.111 | 0.109 |

| 11 | 0.112 - 0.122 | 0.12 |

| 10 | 0.126 - 0.136 | 0.134 |

| 9 | 0.140 - 0.150 | 0.148 |

| 8 | 0.157 - 0.167 | 0.165 |

| 7 | 0.175 - 0.185 | 0.18 |

| Description | Price Per Unit (INR) | Price Per USD |

|---|---|---|

| Inconel Alloy 718 Seamless Tubes As Per Ams 5589 (8 Mm Od X 0.5 Mm Wt X Length 5000 Mm) (10 Pcs/50 Meter) | 127,133 | 1703.45 |

| Inconel Alloy 718 Seamless Tubes As Per Ams 5589 (6mm Od X 1 Mm Wt X Length 5000 Mm) (10 Pcs/50 Meter) | 107,841 | 1444.96 |

| Inconel Alloy 718 Seamless Tubes As Per Ams 5589 (8 Mm Od X 1 Mm Wt X Length 5000 Mm) (10 Pcs/50 Meter) | 99,693 | 1335.78 |

| Inconel 718 Tubing (Approx 3 Lengths ) | 3,192 | 42.77 |

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

| Types of inconel 718 Tube | Out diameter (OD) | Wall thickness | Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| inconel 718 Seamless Tube (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| inconel 718 Welded Tube (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

| Gauge | Outside Diameter Tolerance mm | Regular Wall (RW) mm | Thin Wall (TW) mm | Extra Thin Wall (XTW) mm | Ultra Thin Wall (UTW) mm |

|---|---|---|---|---|---|

| 30 | 0.304 - 0.317 | 0.064 - 0.089 | |||

| 29 | o.330 - 0.342 | 0.064 - 0.089 | |||

| 28 | 0.355 - 0.368 | 0.076 - 0.102 | |||

| 27 | 0.406 - 0.419 | 0.089 - 0.115 | 0.064 - 0.089 | ||

| 26 | 0.457 - 0.469 | 0.089 - 0.114 | |||

| 25 | 0.508 - 0.520 | 0.115 - 0.140 | 0.089 - 0.114 | ||

| 24 | 0.558 - 0.571 | 0.114 - 0.140 | 0.089 - 0.114 | 0.051 - 0.102 | |

| 23 | 0.635 - 0.647 | 0.140 - 0.165 | 0.089 - 0.114 | 0.051 - 0.102 | |

| 22 | 0.711 - 0.723 | 0.140 - 0.165 | 0.096 - 0.121 | 0.077 - 0.102 | 0.051 - 0.102 |

| 21 | 0.812 - 0.825 | 0.140 - 0.165 | 0.102 - 0.127 | 0.051 - 0.102 | |

| 20 | 0.901 - 0.914 | 0.108 - 0.165 | 0.108 - 0.134 | ||

| 19 | 1.054 - 1.079 | 0.166 - 0.216 | 0.102 - 0.140 | 0.070 - 0.108 | |

| 18 | 1.257 - 1.282 | 0.191 - 0.241 | 0.127 - 0.165 | 0.083 - 0.121 | 0.051 - 0.102 |

| 17 | 1.460 - 1.485 | 0.177 - 0.229 | 0.115 - 0.152 | 0.083 - 0.127 | 0.057 - 0.102 |

| 16 | 1.638 - 1.663 | 0.204 - 0.254 | 0.127 - 0.165 | 0.096 - 0.133 | 0.070 - 0.121 |

| 15 | 1.816 - 1.841 | 0.204 - 0.254 | 0.127 - 0.165 | 0.096 - 0.134 | 0.070 - 0.121 |

| 14 | 2.082 - 2.133 | 0.216 - 0.292 | 0.165 - 0.229 | 0.114 - 0.165 | 0.076 - 0.134 |

| 13 | 2.387 - 2.438 | 0.267 - 0.343 | 0.191 - 0.267 | ||

| 12 | 2.743 - 2.749 | 0.267 - 0.321 | |||

| 11 | 3.023 - 3.073 | 0.293 - 0.368 | 0.216 - 0.292 | ||

| 10 | 3.378 - 3.429 | 0.318 - 0.394 | 0.216 - 0.292 |

| Tube O.D. (in.) |

Wall Thickness of Tube (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

from cryogenic up to 1400°F

|

|

| Density | ||

| Specific Gravity | ||

| Melting Range |

Inconel 718 Melting Point

| Density | ||

| Specific Gravity | ||

| Melting Range |

Inconel 718 Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 718 | 2.4668 | N07718 | NCF 718 | – | – | – | – |

| Melting Point | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

| DIMENSIONS | WALL | WEIGHT PER | DIMENSIONS | WALL | WEIGHT PER | |

|---|---|---|---|---|---|---|

| (MM) | (MM) | METRE (KG) | (MM) | (MM) | METRE (KG) | |

| 12.7 x 12.7 | 1.20 | 0.44 | 40 x40 | 1.20 | 1.49 | |

| 12.7 x 12.7 | 1.50 | 0.55 | 40 x40 | 1.50 | 1.85 | |

| 15 x 15 | 1.20 | 0.53 | 40 x40 | 2.00 | 2.45 | |

| 15 x 15 | 1.50 | 0.65 | 40 x40 | 3.00 | 3.75 | |

| 20 x 20 | 1.20 | 0.71 | 50 x50 | 1.50 | 2.32 | |

| 20 x 20 | 1.50 | 0.88 | 50 x50 | 2.00 | 3.08 | |

| 20 x 20 | 2.00 | 1.19 | 50 x50 | 3.00 | 4.65 | |

| 25 x 25 | 1.20 | 0.92 | 60 x60 | 2.00 | 3.71 | |

| 25 x 25 | 1.50 | 1.14 | 60 x60 | 3.00 | 5.49 | |

| 25 x 25 | 2.00 | 1.49 | 70 x70 | 3.00 | 6.53 | |

| 25 x 25 | 3.00 | 2.20 | 80 x80 | 2.00 | 4.98 | |

| 30 x 30 | 1.20 | 1.10 | 80 x80 | 3.00 | 7.53 | |

| 30 x 30 | 1.50 | 1.37 | 100 x 100 | 2.00 | 6.40 | |

| 30 x 30 | 2.00 | 1.84 | 100 x 100 | 3.00 | 9.53 | |

| 30 x 30 | 3.00 | 2.72 | ||||

| O.D. INCHES | WALL THICKNESS INCHES | O.D. +/- INCHES |

|---|---|---|

| 1/2" to 1" incl. | .025 to .065 | .005 |

| Over .065 to .134 | .010 | |

| 1 to 1-1/2" incl. | .025 to .065 | .008 |

| Over .065 to .134 | .010 | |

| 1-1/2" to 2" incl. | .025 to .049 | .010 |

| Over .049 to .083 | .011 | |

| Over .083 to .148 | .012 | |

| 2" to 2-1/2" incl. | .032 to .065 | .012 |

| Over .065 to .109 | .013 | |

| Over .109 to .165 | .014 | |

| 2-1/2" to 3-1/2" incl. | .032 to .165 | .014 |

| Over .165 to .220 | .020 | |

| 3-1/2" to 5" incl. | .083 to .165 | .020 |

| Over .165 to .220 | .025 |