Dowel pins are cylinder-shaped tools that are used with fasteners. They are made to connect various workpieces together in order to secure machinery. An efficient tool that could be used to align devices during reassembly is the Stainless Steel External Threaded Dowel Pin. They are connected to the use of socket screws. The stainless steel dowel pin is used primarily because it can withstand shear pressures. Simply put, a fastener like a socket screw is able to handle the tensile loads in a specific application thanks to the stainless steel metric dowel pin.

Precision, grooved, pullout, large, and standard pins are just a few of the types of pins that a manufacturer of stainless steel dowel pins can make accessible on the market. To fasten components and ensure constant alignment, use a standard 316 stainless steel dowel pin with a chamfered end. The pin's chamfered end allows for simple dowel pin insertion. The precise 416 Stainless Steel Dowel Pin, which is specifically created based on hole size, tolerance, and ductility, performs best in interference fit applications.

The Oversized And Hardened Dowel Pin, which is 0.001 inches larger than regular dowel pins, is also known as a press-fit or repair dowel pin. With the use of these pins, the worn-out holes can be expanded to make room for the new pin. The large 18-8 stainless steel dowel pin is said to be the best option for securing into irregular holes or softer materials.

Before buy compare Stainless Steel Dowel Pin price with Monel Fasteners price list

| ISO standard | ISO 7380, ISO 4032, JIS standards, ISO 4017, ISO 4033 |

|---|---|

| BS | BS 6105 |

| Size |

M6, M30, M12, M10, M16, (M45), M4, M8, M2, M24, (M3.5), M33, M20, M42, (M14), M5, M48, (M18), (M27), (M22), M36, M3, M160 and as per need |

| Grade | 4.8, A2-70, A4-80, 8.8, A4, A4-70, A2, 18-8 Stainless Steel, Studr Bolt |

| Length | 3 milimeter - 200 milimeter |

| Stainless Steel Threads: | METRIC, BSF, UNF, UNC, BSW or as per need |

| DIN | DIN 912, DIN 603, DIN 933, DIN 6923, DIN 931, DIN 7981, DIN 970, DIN 934, DIN916, DIN 7985, DIN 7982, DIN 913, B.S. |

| UTS | UNEF, UNS, NPTF, UNC, NPT, UNF |

| Tolerance | +/-0.01 milimeter - +/-0.05milimeter |

| treatment on Surface |

|

| Type | Round/ Pan/ Hex Head/ Oval/ Truss head |

| Standard: |

JIS, IS, ISO, BS, ANSI, DIN, GB, ASTM and all International Standards |

| Head | Pan head, flat head, oval head, hex head, phillips head |

| Head drive: | Slotted, Six-Lobe, Phillips/Slot, Phillips, etc |

| ASTM Standard | As Per ASTM A380M and A380 |

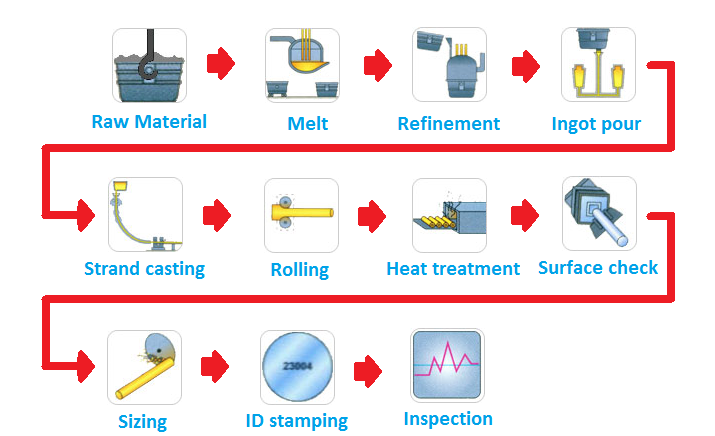

| Manufacturing process | Cold Heading, Heat Treatment, Inspection, Wire Drawing, Packing, Surface Plating, Insert tapping |

| Dowel Pin Manufacturers |

GKW, SPAX® Screws, Kundan, Unbrako, Sundaram Precision, APL, EBY Fastener, Infasco Etc. |

| Certificate provided |

|

| industrial use | Wind tower, Electronic industry, Railway, Construction, Automotive industry, Nuclear power, |

Diameter (Fraction) |

Diameter (Decimal) |

Length (Fraction) |

Length (Decimal) |

Material |

Price in USD $ |

|---|---|---|---|---|---|

1/4 in |

0.2500 in |

1 in |

1.000 in |

Stainless Steel | 1.82 |

1/4 in |

0.2500 in |

1-1/4 in |

1.250 in |

1.82 |

|

1/4 in |

0.2500 in |

1-1/2 in |

1.500 in |

2.37 |

|

1/4 in |

0.2500 in |

3/8 in |

0.375 in |

1.06 |

|

1/4 in |

0.2500 in |

7/16 in |

0.438 in |

1.06 |

|

1/4 in |

0.2500 in |

1/2 in |

0.500 in |

1.32 |

|

1/4 in |

0.2500 in |

9/16 in |

0.563 in |

1.33 |

|

1/4 in |

0.2500 in |

5/8 in |

0.625 in |

1.82 |

|

1/4 in |

0.2500 in |

3/4 in |

0.750 in |

1.82 |

|

1/4 in |

0.2500 in |

7/8 in |

0.875 in |

1.82 |

|

5/16 in |

0.3125 in |

1 in |

1.000 in |

2.23 |

|

5/16 in |

0.3125 in |

1-1/4 in |

1.250 in |

2.28 |

Dowel pins are designed to be used as incredibly precise finding and positioning tools. These sections serve as reference points for other elements of a gathering and are typically inserted into reamed apertures. The use of metal dowel pins can significantly reduce segmental misalignment. A4 and A1 Stainless Steel Dowel Pin are available in our range. Stainless is commonly used to provide precise arrangement in a broad range of designing applications since it can be machined to extremely close resilience tolerances. Dowel Pins may be pressed into the perfect opening because they are made slightly larger than average. Press-fitted dowel pins are less susceptible to vibrational interference.

|

Diameter

|

1/64” to 1 ½”, 0.4 mm to 114.0 mm

|

|

Length

|

3/32” to 10”, 2.4 mm to 254.0 mm

|

|

Fits

|

Press and slip

|

| Single Shear Strength(PSI) | 40,000 min |

| Double Shear Strength (Lbs.) | 930 |

|

Basic Material |

Fastener Finish |

Rockwell Hardness |

Nominal Diameter |

Fastener Length |

|---|---|---|---|---|

| Stainless Steel | Passivated | C36 | 1/16 in | 1/8 in |

| C36 | 1/16 in | 3/16 in | ||

| C36 | 1/16 in | 1/4 in | ||

| C36 | 1/16 in | 5/16 in | ||

| C36 | 1/16 in | 3/8 in | ||

| C36 | 1/16 in | 7/16 in | ||

| C36 | 1/16 in | 1/2 in | ||

| C36 | 1/16 in | 5/8 in | ||

| C36 | 1/16 in | 3/4 in | ||

| C36 | 1/16 in | 7/8 in | ||

| C36 | 3/32 in | 3/16 in | ||

| C36 | 3/32 in | 1/4 in | ||

| C36 | 3/32 in | 5/16 in | ||

| C36 | 3/32 in | 3/8 in | ||

| C36 | 3/32 in | 7/16 in | ||

| C36 | 3/32 in | 1/2 in |

Parts can be ground, polished, super-finished, passivated, or electroplated depending on the application. After super-finishing the underlying Ra 0.05, we may finish the model's mirror surface.

We have capacity of keeping up measurement precision inside 2 microns.

| Hole Material | Mild Steel in Microns | Hardened Steel in Microns | Aluminium / Zinc / Brass in Microns |

|---|---|---|---|

| Transition Fit | Diameter of Pins Less 5 | Diameter of Pins Less 2 | Diameter of Pins Less 5 |

| Interference Fit | Diameter of Pins Less 25 | Diameter of Pins Less 5 | Diameter of Pins Less 35 |

| Clearance Fit | Diameter of Pins Plus 25-60 | ||

| Dowel Diameter m6 | Nominal Diameter |

|---|---|

| 1.002-1.008 | 1.0 |

| 0.802-0.808 | 0.8 |

| 2.002-2.008 | 2.0 |

| 1.502-1.508 | 1.5 |

| 3.002-3.008 | 3.0 |

| 2.502-2.508 | 2.5 |

| 5.004-5.012 | 5.0 |

| 4.004-4.012 | 4.0 |

| 8.006-8.015 | 8.0 |

| 6.004-6.012 | 6.0 |

| 12.007-12.018 | 12.0 |

| 10.006-10.015 | 10.0 |

| 16.007-16.018 | 16.0 |

| 14.007-14.018 | 14.0 |

| 20.008-20.021 | 20.0 |

A dowel should be pushed into a reamed opening using a hammer made of softer material rather than hammered or driven because of the high hardness of the pin's surface. This prevents the pin from snapping and hurting someone. Alert: When introducing Dowel Pins, safety goggles should always be worn.

| Item | Standard | Diameter | Length |

|---|---|---|---|

| Stainless Steel Dowel Pin | DIN 6325 / ISO 8734 | Ø1.0 | 5mm-12mm |

| Ø1.5 | 6mm-20mm | ||

| Ø2.0 | 6mm-30mm | ||

| Ø2.5 | 6mm-30mm | ||

| Ø3.0 | 6mm-40mm | ||

| Ø4.0 | 8mm-50mm | ||

| Ø5.0 | 10mm-60mm | ||

| Ø6.0 | 12mm-80mm | ||

| Ø8.0 | 15mm-100mm | ||

| Ø10 | 20mm-120mm | ||

| Ø12 | 20mm-150mm | ||

| Ø16 | 25mm-150mm | ||

| Ø20 | 30mm-150mm | ||

| Ø25 | 30mm-160mm | ||

| Ø30 | 50mm-200mm |

| SS 304LN Tapered Dowel Pin | SS 304H Roll Dowel Pin |

| Stainless Steel 304 Dowel Pin | 304L Stainless Steel Metal Dowel Pin |

| Stainless Steel 316H Parallel Dowel Pin | 316Ti Stainless Steel Threaded Dowel Pin |

| Stainless Steel 446 Threaded Dowel Pin | 430Ti Stainless Steel Dowel Pin |

| Stainless Steel 316 Spring Post Dowel Pin | 316L Stainless Steel Grooved Dowel Pin |

| SS 317 Dowel Pin | SS 317L Dowel Pin |

| Stainless Steel 347 Roll Dowel Pin | 347H Stainless Steel Spring Post Dowel Pin |

| Stainless Steel 321 Metal Dowel Pin | 321H Stainless Steel Tapered Dowel Pin |

| Parallel Dowel Pins | Oversized Dowel Pin |

| Metric Steel Dowel Pin | Ground Dowel Pin |

| Undersized Dowel Pin | DFARS Dowel Pin |

| SS 904L Grooved Dowel Pin | SS 409 Parallel Dowel Pin |