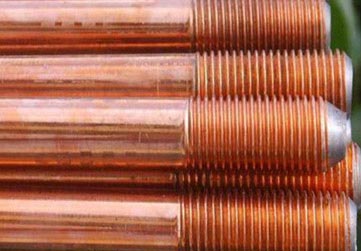

Copper Threaded Rod

The usage of copper, an old metal, is nevertheless important in many modern applications. The qualities of the copper threaded rod make it useful for a variety of applications, including plumbing and the marine sector. Several alloys have used copper as a metal to enhance particular properties. The resistance of solid copper threaded rod to brine or salt water solutions is extremely great. Use of a copper threaded earth rod, specifically, has significant advantages in marine engineering applications.

The threaded copper bond earth rod provides high resistance to seawater as well as anti-biofouling qualities. The accumulation of different types of plants, algae, microbes, or small animals on wet metal surfaces is known as biofouling. Steel or other alloys that are exposed to biofouling in the water may develop structural or other functional flaws. The 8-32 threaded copper rod is an essential component of maritime applications such as shipbuilding, boat construction, and yachting because it possesses inherent anti-biofouling qualities. Additionally, copper has exceptional ductility and malleability, which make it simpler to mould the metal into different forms or create the 3/4 copper threaded rod.

High thermal conductivity or high electrical conductivity may be necessary for some applications, such as power generation and heat exchangers. A threaded copper ground rod, which exhibits excellent conductivity to both heat and electricity, is required for usage in such applications. Some materials, like the 3/8 copper threaded rod, are chosen for their colour and visual appeal even if the choice of a material is predicated on its functionality. The 1/2 copper threaded rod may be taken into consideration for its design appeal due to the metal's extremely distinctive pinkish-orange colour.

| Description | Price list |

|---|---|

| DIN975 DIN 976 Copper Full Thread Stud Bolt Threaded Rods | US $ 0.01-0.5 / Piece |

| Copper-Bonded Steel Ground Rod Threaded or Pointed | US $ 1.9 / Piece |

| Threaded Copper Clad Steel Ground Rod | Min. Order: 500 Pieces |

| Copper Brazing Rod, Copper Threaded Rod | US $ 5-12 / Yard |

| Fully Threaded Copper Threaded Rod |

US $ 0.01-0.5 / Piece |

| Non-Threaded Copper Grounding Rod Earth Rod Earthing Rod | US $ 1.9 / Piece |

| Copper Tapered All Threaded Rod |

US $ 0.5-0.8 / Piece |

| DIN975 Copper All Thread Studs Full Threaded Rod | US $ 1000-1020 / Ton |

| Full Threaded M8 1m Long M10 M12 Copper Thread Bar DIN975 DIN976 All Thread Rods | US $ 0.01-0.5 / Piece |

| Copper C71000 C63000 ASTM A453 660 Class a B C D Threaded Rod with Heavy Hex Nut | US $ 0.01-0.5 / Piece |

Standards |

Designation |

|---|---|

| Thread Requirements | ASME B1.1, UNC & UNF, Class 2A |

| Copper Threaded Rod Coatings | PTFE |

| Production Process | Wire Drawing, Cold Heading, Heat Treatment, Inspection, Packing, Insert tapping, Surface Plating |

| Heads | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc |

Copper Threaded Rod Dimensions |

ASME B18.2.1, B18.3 |

Extra Certificate |

PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified, |

| Neck | Hex, Square, Triangular, Oval & Knurled etc |

Copper Threaded Rod Origin of Melt |

East Europe/Korea/South America/ Japan |

Extra Need |

NACE MR0103 /MR0175 / ISO 15156 Compliance |

Configuration of Threads |

ASME B1.1 2A/3A Inch and B1.13M 6h Metric Coarse Threads |

Origin of Product |

Indian |

Copper Threaded Rod Certification |

As per ASME & ASTM Codes Dual Certified |

necessary need |

Free from Mercury Contamination and Radioactive |

Copper Threaded Rod Wt Per 100′ |

Copper Threaded RodSize |

Copper Threaded Rod Pieces Per Tube |

|---|---|---|

12.03 |

1/4-20 |

50 |

20.01 |

5/16-18 |

35 |

29.06 |

3/8-16 |

25 |

40.06 |

7/16-14 |

17 |

53.09 |

1/2-13 |

12 |

67.06 |

9/16-12 |

10 |

85.02 |

5/8-11 |

8 |

124.09 |

3/4-10 |

5 |

172.04 |

7/8-9 |

4 |

225.06 |

1-8 |

2 |

284.02 |

1 1/8-7 |

1 |

290.09 |

1 1/8-8 |

1 |

357.06 |

1 1/4-7 |

1 |

365.08 |

1 1/4-8 |

1 |

517.08 |

1 1/2-6 |

1 |

539.07 |

1 1/2-8 |

1 |

703.00 |

1 3/4-5 |

1 |

922.00 |

2″-4 1/2 |

1 |

Copper Threaded Rod Thread |

Copper Threaded Rod Weight per metre |

Copper Threaded Rod Strength |

|||

|---|---|---|---|---|---|

Copper Threaded Rod Class 70 |

Copper Threaded Rod Class 80 |

||||

0.02% proof |

UTS |

0.02% proof |

UTS |

||

Kg/m |

kN |

kN |

kN |

kN |

|

M12 |

0.072 |

41.00 |

64.00 |

54.00 |

73.00 |

M16 |

1.031 |

70.07 |

109.09 |

94.02 |

125.06 |

M20 |

2.005 |

110.03 |

171.05 |

147.00 |

196.00 |

M24 |

2.096 |

158.09 |

247.01 |

211.08 |

282.04 |

M27 |

3.083 |

206.06 |

321.03 |

275.04 |

367.02 |

M30 |

4.070 |

252.06 |

392.07 |

336.06 |

448.08 |

M33 |

5.078 |

312.03 |

485.08 |

416.04 |

555.02 |

M36 |

6.084 |

367.07 |

571.09 |

490.02 |

653.06 |

M39 |

8.014 |

439.02 |

683.02 |

585.06 |

780.08 |

M42 |

9.038 |

504.05 |

784.07 |

672.06 |

896.06 |

M45 |

10.090 |

587.07 |

914.02 |

783.06 |

1044.08 |

M48 |

12.032 |

662.09 |

1031.01 |

883.08 |

1178.04 |

M52 |

14.065 |

791.01 |

1230.06 |

1054.08 |

1406.04 |

| Torque Specifications | |||||||

|---|---|---|---|---|---|---|---|

| Bolt Size Inches or # |

Threads Per Inch |

Standard Dry Torque in Inch-Pounds | |||||

| #2 | 56 | 2.5 | 2.6 | ||||

| 64 | 3.0 | 3.2 | |||||

| #3 | 48 | 3.9 | 4.0 | ||||

| 56 | 4.4 | 4.6 | |||||

| #4 | 40 | 5.2 | 5.5 | ||||

| 48 | 6.6 | 6.9 | |||||

| #5 | 40 | 7.7 | 8.1 | ||||

| 44 | 9.4 | 9.8 | |||||

| #6 | 32 | 9.6 | 10.1 | ||||

| 40 | 12.1 | 12.7 | |||||

| #8 | 32 | 19.8 | 20.7 | ||||

| 36 | 22.0 | 23.0 | |||||

| #10 | 24 | 22.8 | 23.8 | ||||

| 32 | 31.7 | 33.1 | |||||

| Bolt Size Inches or # |

Threads Per Inch |

Standard Dry Torque in Inch-Pounds | |||||

| 1/4 | 20 | 75.2 | 78.8 | ||||

| 28 | 94.0 | 99.0 | |||||

| 5/16 | 18 | 132 | 138 | ||||

| 24 | 142 | 147 | |||||

| 3/8 | 16 | 236 | 247 | ||||

| 24 | 259 | 271 | |||||

| 7/16 | 14 | 376 | 393 | ||||

| 20 | 400 | 418 | |||||

| 1/2 | 13 | 517 | 542 | ||||

| 20 | 541 | 565 | |||||

| Bolt Size Inches or # |

Threads Per Inch |

Standard Dry Torque in Inch-Pounds | |||||

| 9/16 | 12 | 682 | 713 | ||||

| 18 | 752 | 787 | |||||

| 5/8 | 11 | 1110 | 1160 | ||||

| 18 | 1244 | 1301 | |||||

| 3/4 | 10 | 1530 | 1582 | ||||

| 16 | 1490 | 1558 | |||||

| 7/8 | 9 | 2328 | 2430 | ||||

| 14 | 2318 | 2420 | |||||

| 1 | 8 | 3440 | 3595 | ||||

| 14 | 3110 | 3250 | |||||

| Bolt Size Inches or # |

Threads Per Inch |

Standard Dry Torque in Foot-Pounds | |||||

| 1 1/8 | 7 | 413 | 432 | ||||

| 12 | 390 | 408 | |||||

| 1 1/4 | 7 | 523 | 546 | ||||

| 12 | 480 | 504 | |||||

| 1 1/2 | 6 | 888 | 930 | ||||

| 12 | 703 | 732 | |||||

Environmental Properties |

|

|---|---|

Resistance Factors 1=Poor 5=Excellent |

|

Fresh Water |

5 |

Flammability |

5 |

Oxidation at 500C |

3 |

Organic Solvents |

5 |

Strong Acid |

2 |

Sea Water |

5 |

UV |

5 |

Strong Alkalis |

5 |

Weak Acid |

4 |

Wear |

5 |

Weak Alkalis |

5 |

Property |

Minimum Value (S.I.) |

Maximum Value (S.I.) |

Units (S.I.) |

Minimum Value (Imp.) |

Maximum Value (Imp) |

Units (Imp.) |

|---|---|---|---|---|---|---|

Atomic Volume (average) |

0.00071 |

0.00073 |

m3/kmol |

433.0268 |

445.0473 |

in3/kmol |

Density |

8.093 |

8.094 |

Mg/m3 |

557.0482 |

558.0106 |

lb/ft3 |

Energy Content |

100 |

130 |

MJ/kg |

10833.09 |

14084 |

kcal/lb |

Bulk Modulus |

130 |

145 |

GPa |

18.08549 |

21.00305 |

106 psi |

Compressive Strength |

45 |

330 |

MPa |

6.05267 |

47.08625 |

ksi |

Ductility |

0.004 |

0.05 |

0.004 |

0.05 |

NULL |

|

Elastic Limit |

45 |

330 |

MPa |

6.05267 |

47.08625 |

ksi |

Endurance Limit |

70 |

140 |

MPa |

10.01526 |

20.03053 |

ksi |

Fracture Toughness |

40 |

100 |

MPa.0m1/2 |

36.04019 |

91.00047 |

ksi.0in1/2 |

Hardness |

400 |

1150 |

MPa |

58.00151 |

166.0793 |

ksi |

Loss Coefficient |

3.05e-005 |

0.0002 |

3.05e-005 |

0.0002 |

NULL |

|

Modulus of Rupture |

45 |

330 |

MPa |

6.05267 |

47.08625 |

ksi |

Poisson’s Ratio |

0.034 |

0.035 |

0.034 |

0.035 |

NULL |

|

Shear Modulus |

44 |

49 |

GPa |

6.038166 |

7.010685 |

106 psi |

Tensile Strength |

210 |

390 |

MPa |

30.04579 |

56.05647 |

ksi |

Young’s Modulus |

121 |

133 |

GPa |

17.05496 |

19.029 |

106 psi |

Glass Temperature |

K |

°F |

||||

Latent Heat of Fusion |

200 |

210 |

kJ/kg |

85.09841 |

90.02833 |

BTU/lb |

Maximum Service Temperature |

350 |

400 |

K |

170.033 |

260.033 |

°F |

Melting Point |

1320 |

1355 |

K |

1916.033 |

1979.033 |

°F |

Minimum Service Temperature |

0 |

0 |

K |

-459.067 |

-459.067 |

°F |

Specific Heat |

372 |

388 |

J/kg.0K |

0.0287875 |

0.0300257 |

BTU/lb.0F |

Thermal Conductivity |

147 |

370 |

W/m.0K |

275.0189 |

692.0652 |

BTU.0ft/h.0ft2.0F |

Thermal Expansion |

16.08 |

17.09 |

10-6/K |

30.024 |

32.022 |

10-6/°F |

Breakdown Potential |

MV/m |

V/mil |

||||

Dielectric Constant |

NULL |

|||||

Resistivity |

1.082 |

4.09 |

10-8ohm.0m |

1.082 |

4.09 |

10-8 ohm.0m |

Material designation |

COMPOSITION %

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Element

|

Pb

|

Ag

|

Cu

|

O

|

Bi

|

P

|

Other elements (see note)

|

||||

Symbol |

Number

|

Total

|

Excluding

|

||||||||

Cu-ETP |

CW004A

|

minimum

maximum |

0,005 |

99,90(1)

|

0,040(2) |

0,0005 |

0,03 |

Ag. O

|

|||

Cu-FRHC |

CW005A

|

minimum

maximum |

99,90(1)

|

0,040(2) |

0,04 |

Ag. O

|

|||||

Cu-OF |

CW008A

|

minimum

maximum |

0,005 |

99,95(1)

|

-(3) |

0,0005 |

0,03 |

Ag.

|

|||

CuAg 0,04 |

CW0011A

|

minimum

maximum |

0,03

0,05 |

Balance

|

0,040 |

0,0005 |

0,03 |

Ag. O

|

|||

CuAg 0,07 |

CW0012A

|

minimum

maximum |

0,06

0,08 |

Balance

|

0,040 |

0,0005 |

0,03 |

Ag. O

|

|||

CuAg 0,10 |

CW0013A

|

minimum

maximum |

0,08

0,12 |

Balance

|

0,040 |

0,0005 |

0,03 |

Ag. O

|

|||

CuAg 0,04P |

CW0014A

|

minimum

maximum |

0,03

0,05 |

Balance

|

-(3) |

0,0005 |

0,001

0,007 |

0,03 |

Ag. P

|

||

CuAg 0,07P |

CW0015A

|

minimum

maximum |

0,06

0,08 |

Balance

|

-(3) |

0,0005 |

0,001

0,007 |

0,03 |

Ag. P

|

||

CuAg 0,10P |

CW0016A

|

minimum

maximum |

0,08

0,12 |

Balance

|

-(3) |

0,0005 |

0,001

0,007 |

0,03 |

Ag. P

|

||

CuAg 0,04(OF) |

CW0017A

|

minimum

maximum |

0,03

0,05 |

Balance

|

-(3) |

0,0005 |

0,0065 |

Ag. O

|

|||

CuAg 0,07(OF) |

CW0018A

|

minimum

maximum |

0,06

0,08 |

Balance

|

-(3) |

0,0005 |

0,0065 |

Ag. O

|

|||

CuAg 0,10(OF) |

CW0019A

|

minimum

maximum |

0,08

0,12 |

Balance

|

-(3) |

0,0005 |

0,0065 |

Ag. O

|

|||

Cu-PHC |

CW0020A

|

minimum

maximum |

0,005 |

99,95(1)

|

-(3) |

0,0005 |

0,001

0,006 |

0,03 |

Ag. P

|

||

Cu-HCP |

CW0021A

|

minimum

maximum |

0,005 |

99,95(1)

|

-(3) |

0,0005 |

0,002

0,007 |

0,03 |

Ag. P

|

||

| Canada, Philippines, Malaysia, Singapore | Copper Coated Thread Ground Rod |

| Romania, Europe, Japan, Malaysia | Copper Clad Steel Rod |

| Malaysia, Sweden, Colombia, China | Copper Thread Rod Full Thread M20X500 Brass/Copper Thread Rod |

| Los Alamos -Mexico, Malaysia, Taiwan, Philippines | Thread Copper Coated Ground Rod |

| NY 12203 (USA), Singapore, South Korea, Malaysia | Threaded Copperbond Steel Ground Rod 250microns |

| Philippines, Dammam -KSA, Indonesia, Belgium | Copper Drill Connecting Threaded Rod |

| Europe, Qatar, France, Thailand | Cheap Threaded Driving Tip for 3/4" Copper Rod |

| Thailand, Czechia, Germany, Malaysia | Copper Internal Threaded Grounding Rods Earthing Rod |

| Bangladesh, Malaysia, USA, Finland | Hollow Threaded Copper Rods |

| Kuwait, South Africa, Saudi Arabia (KSA), Brazil | Custom CNC Machining Hollow/ Threaded Copper Rods |

| Singapore, Bahrain, South Africa | 3/8-16 X 6" Zinc Plated Threaded Rod Studs Atr Full Thread Steel |

| , UK, Philippines, Australia, Nigeria | Galvanized copper Threaded Rod |

| Hong Kong, Oman, Malaysia, UAE | DIN 975 Copper Threaded Rod with Coarse Thread |

| , Iran, Chile, Italy, Singapore | Hollow Threaded Copper Rods |

| Norway, United Arab Emirates (UAE), Turkey, Malaysia | DIN All Size Copper Threaded Rod |

| Russia, Netherlands, Malaysia, Dubai | Copper DIN975 Full Threaded Rod |

| Ellington -United States, Canada, UK | 0.25"-20 Copper Threaded Coarse Rod 110 72" Length |

| Malaysia, Netherlands, Turkey, Norway | 0.25"-20 Copper Threaded Coarse Rod 110 36" Length |

| United Arab Emirates (UAE), South Korea | 0.5"-13 Copper Threaded Coarse Rod 110 36" Length |

| Spain, Mexico, UK, Egypt, Brazil | 0.3125"-18 Copper Threaded Coarse Rod 110 36" Length |

| USA, Malaysia, Finland, Bangladesh | 0.3125"-18 Copper Threaded Coarse Rod 110 72" Length |

| Philippines, Canada, Romania | 0.625"-11 Copper Threaded Coarse Rod 110 36" Length |

| France, Qatar, Thailand, Europe | 0.75"-10 Copper Threaded Coarse Rod 110 36" Length |

| Mexico, Egypt, Spain, UK | High Strength Hardened Copper Threaded Rod All Thread Plain |